Preparation method of lithium battery diaphragm, lithium battery diaphragm and lithium ion battery

A lithium battery diaphragm and diaphragm technology, which is applied in the direction of separators/films/diaphragms/spacers, secondary batteries, battery pack components, etc., can solve the contradiction between high electron conductivity and mechanical properties, weak cycle stability, Low temperature conductivity and other issues, to achieve the effect of good battery cycle performance, good thermal dimensional stability, and high air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

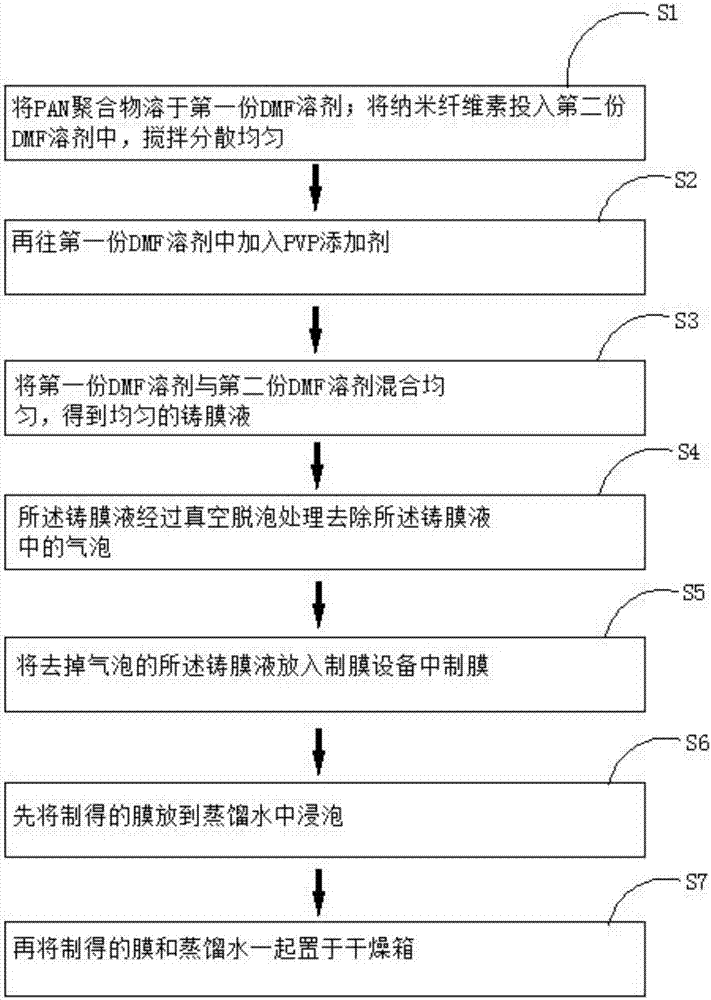

Method used

Image

Examples

specific Embodiment

[0029] Optimize the above scheme, remove ionized water in the coagulation bath, and control the temperature of the coagulation bath at 65°C. The purpose of removing ionized water is to prevent harmful impurities from affecting the purity of the diaphragm. A coagulation bath with a relatively high temperature facilitates more dispersion during stirring. Quickly and evenly.

[0030] To further optimize the above scheme, the film-making equipment can use a glue leveler, or a coating machine can be used to make a film by coating.

[0031] To further optimize the above scheme, the stirring in step S3 needs to be stirred for 2 hours, so that the dispersion can be more uniform. The high-speed stirring in step S4 needs to use a mixer, and the speed of the mixer is controlled between 8000 ~ 12000r / min, generally using more than 10000r / min Rotational speed for better dispersion.

[0032] Further optimize the above-mentioned scheme, the concentration scope of PAN (polyacrylonitrile) polym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com