Synthesis method of 1,2-diphenoxyethane thermosensitive sensitizer

A diphenoxyethane heat-sensitive sensitizer and a technology of a synthesis method, which are applied in the first field, can solve problems such as high difficulty in industrialization, long reaction time, and large investment in equipment, and achieve short reaction time, easy conditions, and easy raw materials. The effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

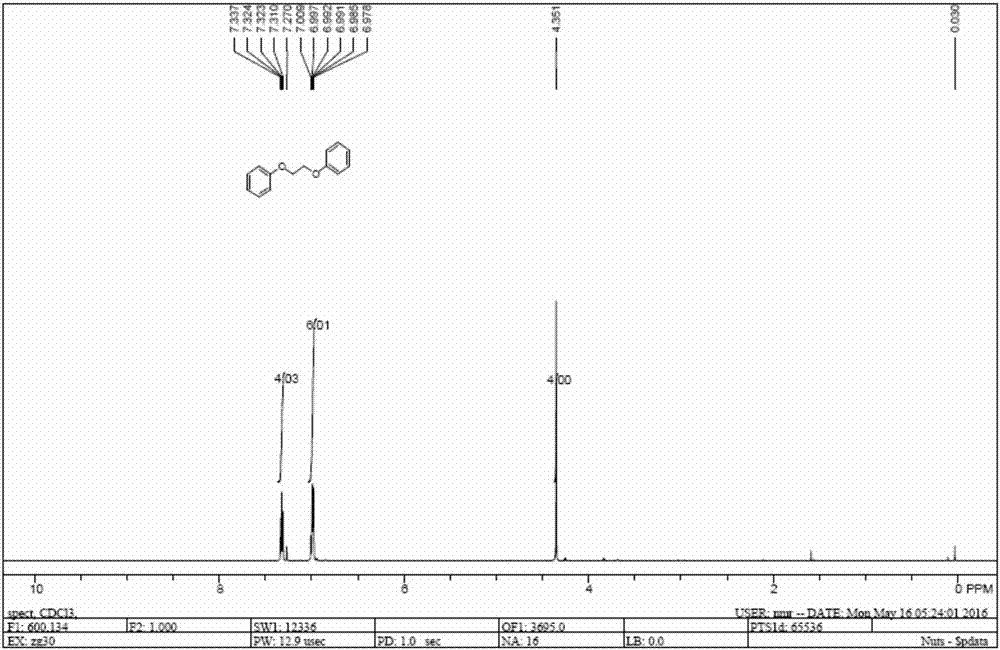

[0019] Present embodiment 1, the synthetic route of 2-diphenoxyethane thermal sensitizer is as follows:

[0020]

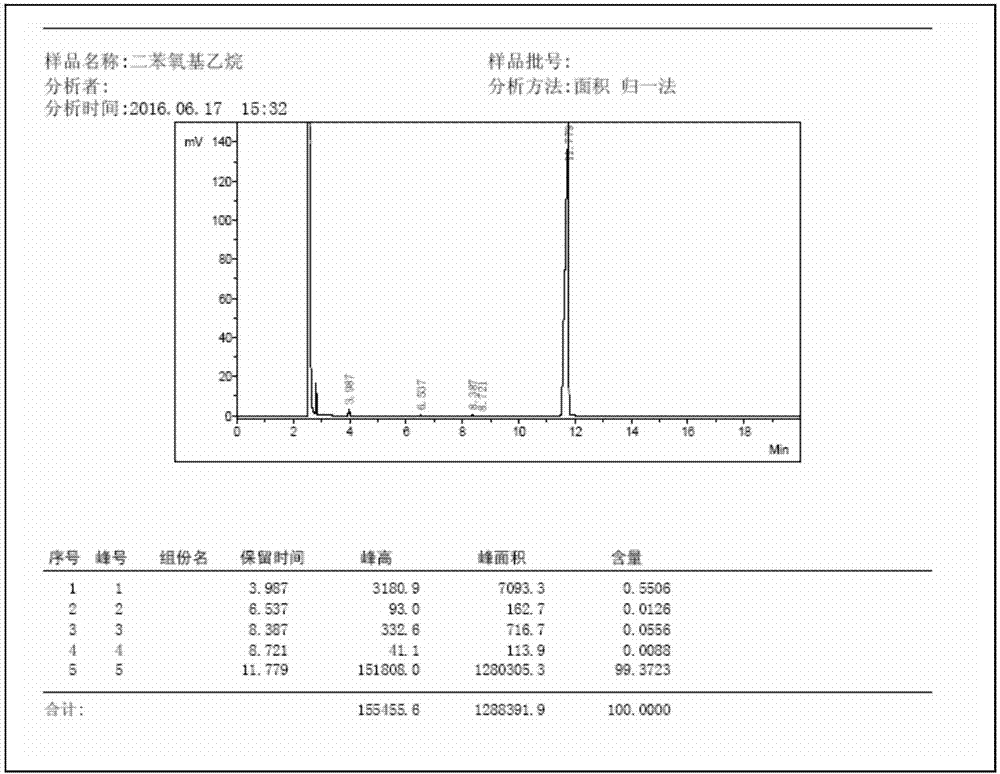

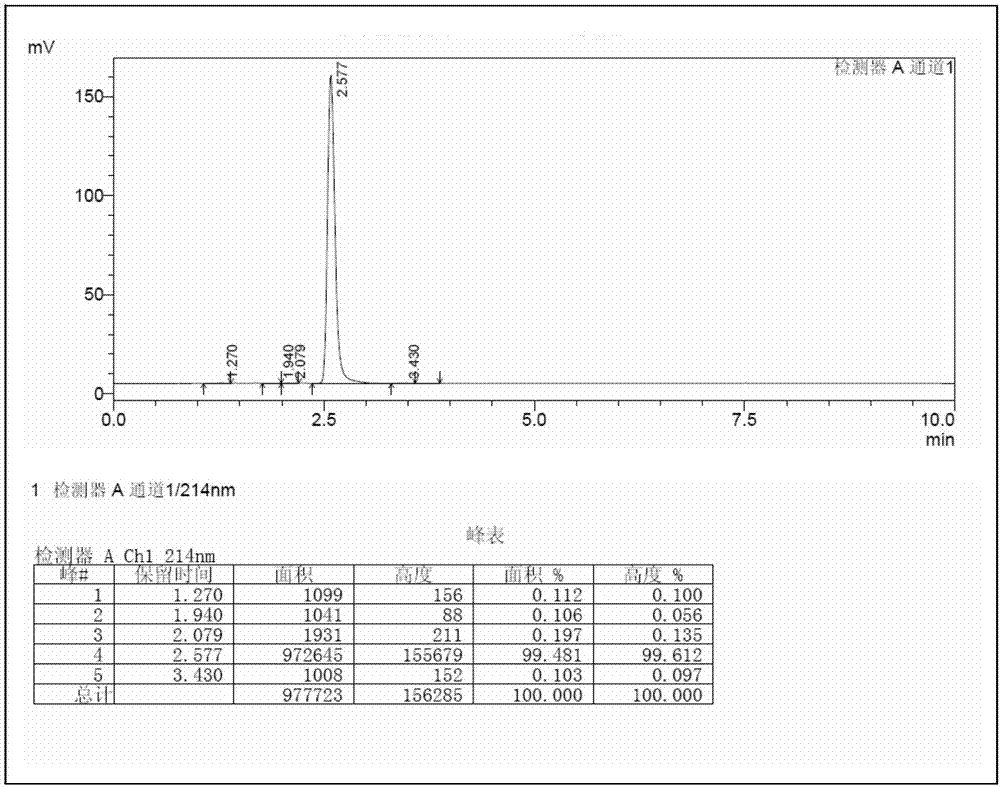

[0021] Add 100kg of melted phenol and 420kg of dichloroethane into the reactor, heat up to 85°C and reflux, slowly add 161kg of 1,8-diazabicyclo[5.4.0]undec-7-ene (DBU) dropwise, After dropping, react for 3 hours, the gas phase detection phenol reaction is complete, and the reaction product is 2-chlorophenetole; Dichloroethane is distilled off under reduced pressure, and 1,8-diazabicyclo[5.4.0]undec-7 -ene (DBU) 161kg, heat up to 130°C, add 100kg of phenol dropwise, follow up and detect that the reaction of 2-chlorophenetole is complete, stop adding phenol dropwise, cool down to 100°C, add 100kg of water, stir for 1h, let go of the water phase, and then add the organic phase Add 100kg of water, stir for 1h, slowly cool down, solids are precipitated, filter, and the filter cake is recrystallized with ethanol to obtain 408kg of white crystals, the yield is 89.82%...

Embodiment 2

[0026] Present embodiment 1, the synthetic route of 2-diphenoxyethane thermal sensitizer is as follows:

[0027]

[0028] Add 100kg of melted phenol and 420kg of dichloroethane into the reactor, heat up to 85°C and reflux, slowly add 1,4-diazabicyclo[2.2.2]octane (DABCO) 119kg dropwise, After reacting for 3 hours, the phenol reaction was detected by the gas phase, and the reaction product was 2-chlorophenetole; the dichloroethane was distilled off under reduced pressure, and 1,4-diazabicyclo[2.2.2]octane (DABCO) 119kg was added , raise the temperature to 130°C, add 100kg of phenol dropwise, track and detect that the reaction of 2-chlorophenetole is complete, stop the dropwise addition of phenol, cool down to 100°C, add 100kg of water, stir for 1h, let go of the water phase, add 100kg of water to the organic phase, stir for 1h, Slowly lower the temperature, solids are precipitated, filtered, and the filter cake is recrystallized with ethanol to obtain 391kg of white crystals...

Embodiment 3

[0030] Present embodiment 1, the synthetic route of 2-diphenoxyethane thermal sensitizer is as follows:

[0031]

[0032] Add 100kg of melted phenol and 420kg of dichloroethane into the reaction kettle, raise the temperature to 85°C and reflux, slowly add 138kg of N,N-diisopropylethylamine (DIPEA) dropwise, and react for 4 hours, and detect the phenol by gas phase The reaction is complete, and the reaction product is 2-chlorophenetole; the dichloroethane is distilled off under reduced pressure, and 138kg of N,N-diisopropylethylamine (DIPEA) is added, the temperature is raised to 130°C, and 100kg of phenol is added dropwise. Detect that the reaction of 2-chlorophenetole is complete, stop adding phenol dropwise, cool down to 100°C, add 100kg of water, stir for 1h, let go of the water phase, add 100kg of water to the organic phase, stir for 1h, cool down slowly, solids are precipitated, filter, and use as a filter cake Recrystallization from ethanol gave 332kg of white crystal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com