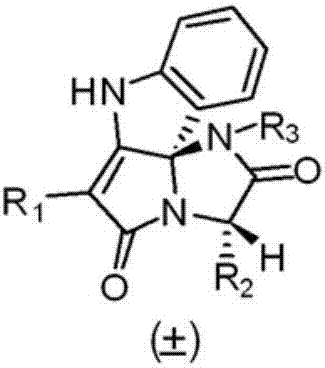

Preparation method of spiroindoline compound

A technology for indoline spiro and ring compounds, which is applied in the field of rapid preparation of indoline spiro compounds, achieving the effects of short synthesis route, high atom utilization rate and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

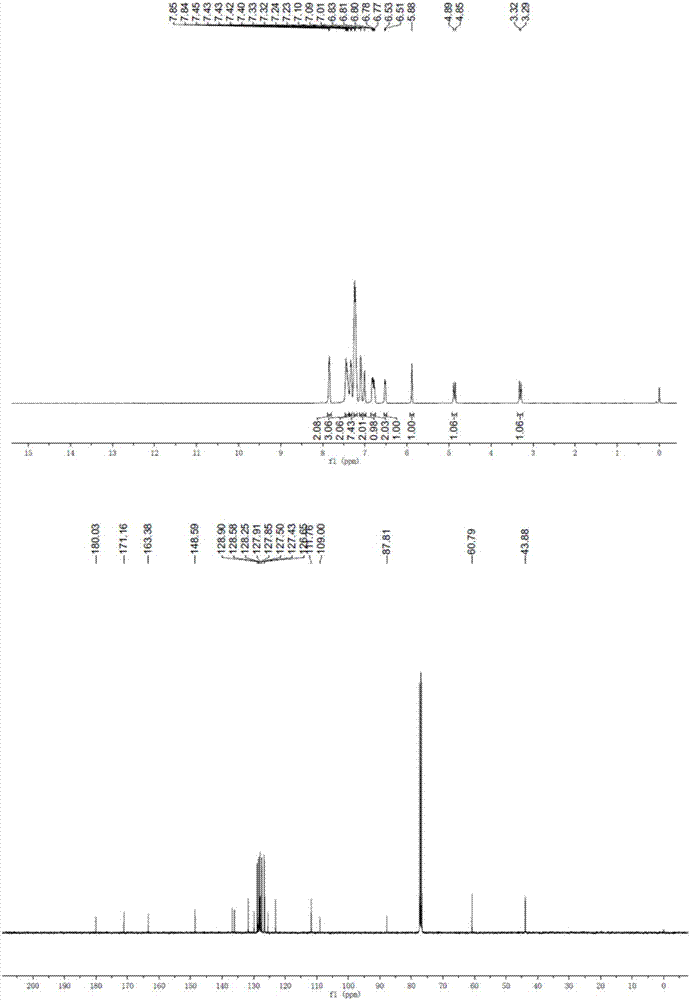

Embodiment 1

[0044] where R 1 is aryl, R 2 is aryl, R 3 is an alkyl group, namely (±)-1-benzyl-3,6-diphenyl-1 H -imidazo[1',2':1,2]pyrrolo[3,2- b ]indole-2,5(3 H , 7 H )-diketone synthesis, the specific steps are as follows:

[0045] In a microwave reaction tube of 10 ml size, the 3-amino-1 H - Indole-1-carboxylate tert-butyl ester (1.0 mmol) and benzaldehyde (1.0 mmol) were dissolved in 2.0 mL of methanol solution, followed by benzoylformic acid (1.0 mmol) and benzylisocyanate (1.0 mmol) was added to the solution one by one, the reaction solution was stirred overnight at room temperature, and then the isocyanate was detected by thin-layer chromatography. If there was no remaining isocyanine raw material, the solution was dried with nitrogen, and then dissolved in 10% TFA / DCE (5 mL). In the microwave 100 o After reacting with C for 10 minutes, the reaction mixture was diluted with ethyl acetate (15 ml), washed with saturated sodium carbonate solution and sodium chloride solution ...

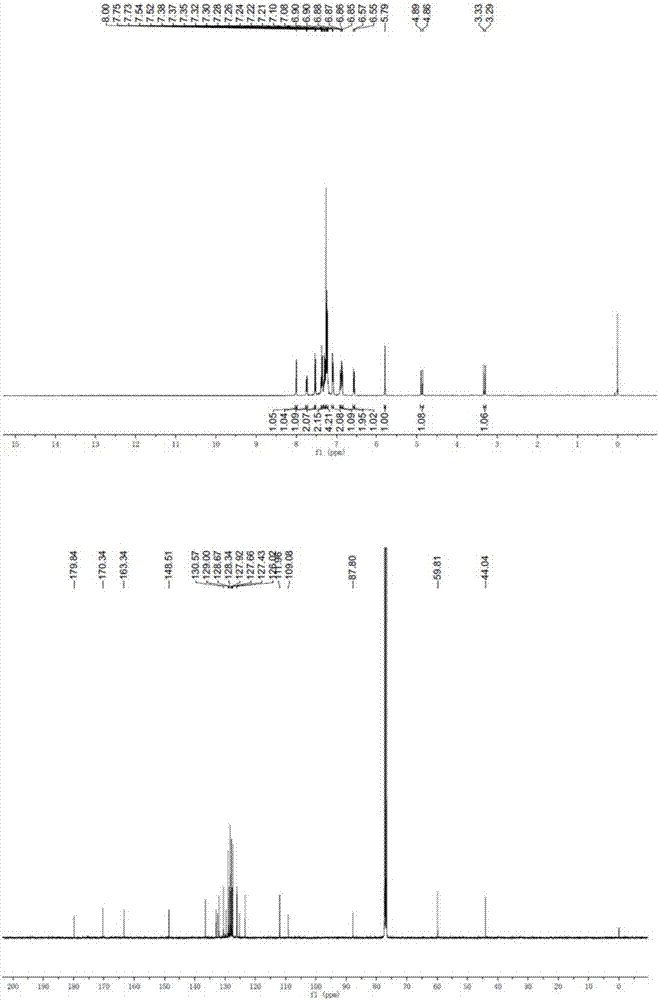

Embodiment 2

[0048] where R 1 is aryl, R 2 is aryl, R 3 is an alkyl group, namely (±)-1-benzyl-3-(3,4-dichlorophenyl)-6-phenyl-1 H -imidazo[1',2':1,2]pyrrolo[3,2- b ] indole-2,5 (3 H , 7 H )-diketone synthesis, the specific steps are as follows:

[0049] In a microwave reaction tube of 10 ml size, the 3-amino-1 H -Indole-1-carboxylate tert-butyl ester (1.0 mmol) and 3,4-dichlorobenzaldehyde (1.0 mmol) were dissolved in 2.0 mL of methanol solution, and then benzoylformic acid (1.0 mmol ) and benzyl isocyanide (1.0 mmol) were sequentially added to the solution, the reaction solution was stirred overnight at room temperature, and then the isocyanate was detected by thin-layer chromatography. If there was no remaining isocyanine raw material, the solution was dried with nitrogen, and Redissolve in 10% TFA / DCE (5 mL). In the microwave 100 o After reacting with C for 10 minutes, the reaction mixture was diluted with ethyl acetate (15 ml), washed with saturated sodium carbonate solution ...

Embodiment 3

[0052] where R 1 is aryl, R 2 is aryl, R 3 is an alkyl group, namely (±)-1-benzyl-3-(4-methoxyphenyl)-6-phenyl-1 H -imidazo[1',2':1,2]pyrrolo[3,2- b ]indole-2,5(3 H , 7 H )-diketone synthesis, the specific steps are as follows:

[0053] In a microwave reaction tube of 10 ml size, the 3-amino-1 H -Indole-1-carboxylate tert-butyl ester (1.0 mmol) and 4-methoxybenzaldehyde (1.0 mmol) were dissolved in 2.0 mL of methanol solution, followed by benzoylformic acid (1.0 mmol) and benzyl isocyanide (1.0 mmol) were sequentially added to the solution, the reaction solution was stirred overnight at room temperature, and then the isocyanate was detected by thin-layer chromatography. If there was no remaining isocyanine raw material, the solution was dried with nitrogen, and then Dissolve in 10% TFA / DCE (5 mL). In the microwave 100 o After reacting with C for 10 minutes, the reaction mixture was diluted with ethyl acetate (15 ml), washed with saturated sodium carbonate solution and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com