Preparation method and application of polyethylene film

A technology of polyethylene film and ethylene, applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of additive overflow and affect the application of films, etc., achieve the improvement of space-time yield and heat removal ability , the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

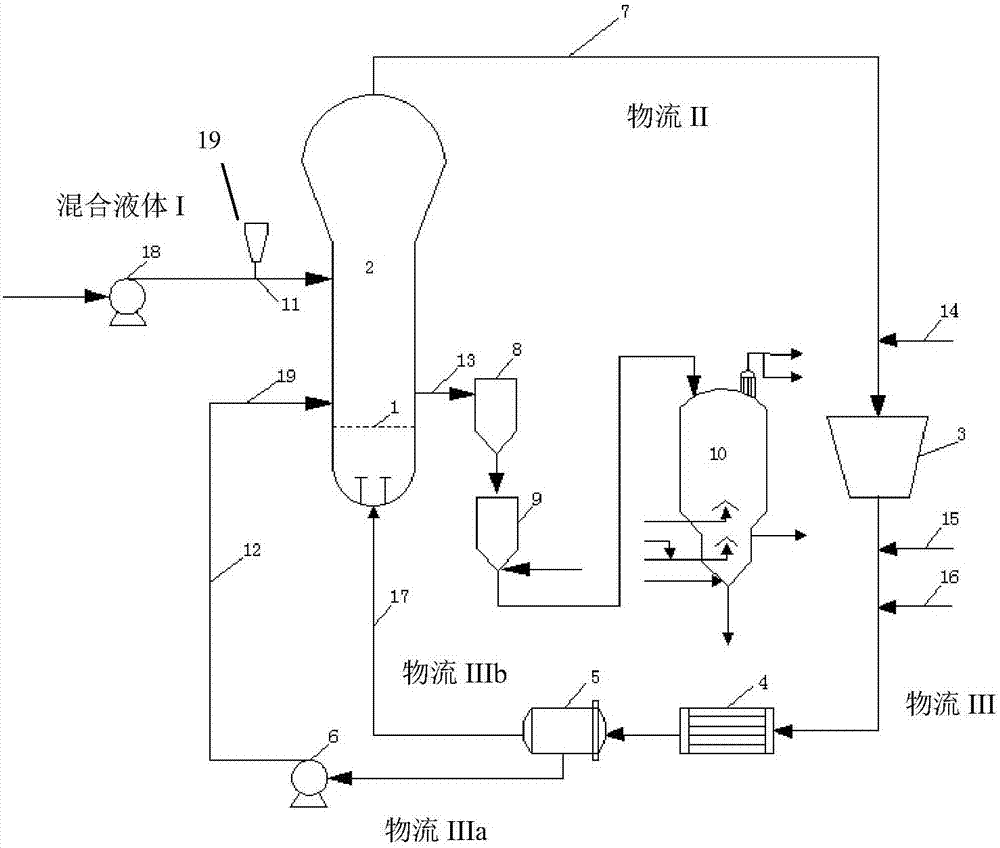

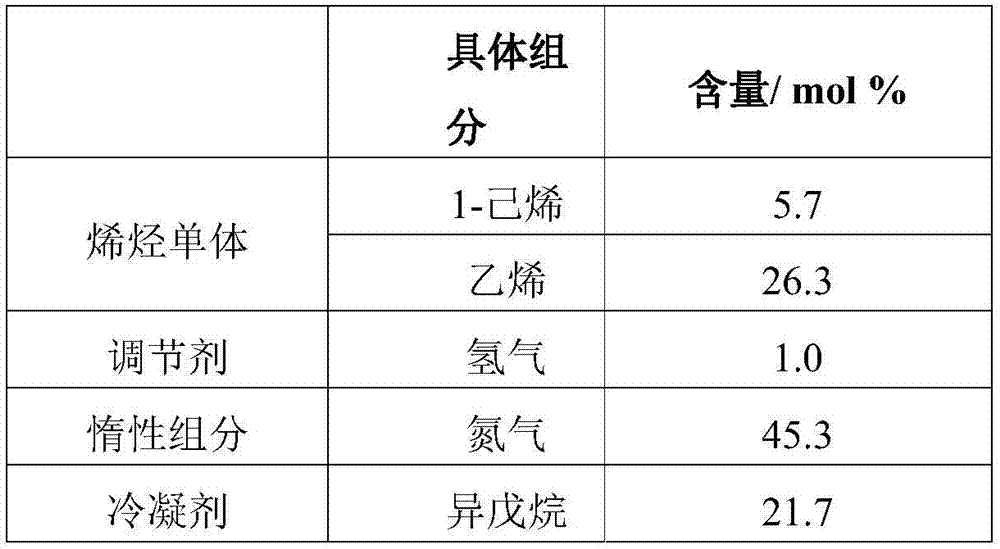

[0085] This embodiment adopts the TiCl supported by magnesium chloride 3 Main catalyst (main catalyst feed rate 2.18kg / h), Ziegler-Natta catalyst with triethylaluminum as cocatalyst. Wherein, the molar ratio of the main catalyst and the co-catalyst is 3.11 in terms of Ti / Al. Reaction flow see figure 1 .

[0086] The mass flow rate of mixed liquid I is 1.8 t / h, accounting for 0.42% of the mass flow rate of stream II. In the mixed liquid I, the alkane isopentane content accounts for 50% by weight of the mixed liquid (the molar content is 49%), and the olefin content accounts for 50% by weight of the mixed liquid (the molar content is 51%). The content of 1-hexene accounts for 45.1% by weight of the mixed liquid (the molar content is 38.5%). Mixed liquid I also contained 200 ppm of triethylaluminum cocatalyst.

[0087] The superficial fluidization gas velocity in the reactor was 0.75 m / s. The pressure of the reactor was 2.1 MPa, and the temperature was 89°C.

[0088] After...

Embodiment 2

[0095] This embodiment adopts the TiCl supported by magnesium chloride 3 Main catalyst (loading capacity is 1.75kg / h), Ziegler-Natta catalyst with triethylaluminum as cocatalyst. Wherein, the molar ratio of the main catalyst and the co-catalyst is 3.11 in terms of Ti / Al. Reaction flow see figure 1 .

[0096] The mass flow rate of mixed liquid I is 1.3t / h, accounting for 0.30% of the mass flow rate of stream II. In the mixed liquid I, the alkane isopentane content accounts for 45% by weight of the mixed liquid (the molar content is 35%), and the olefin content accounts for 55% by weight of the mixed liquid (the molar content is 65%), wherein the ethylene content accounts for 45% by weight of the mixed liquid (the molar content is 65%). 8.8% by weight (mole content is 17.8%), 1-butene content accounts for 46.2% by weight of the mixed liquid) (molar content is 47.2%), also contains 180ppm triethylaluminum cocatalyst in the mixed liquid.

[0097] The superficial fluidization g...

Embodiment 3

[0106] This embodiment adopts the TiCl supported by magnesium chloride 3 It is a Ziegler-Natta catalyst (feed amount of the main catalyst is 2.03kg / h), and triethylaluminum is used as a cocatalyst. Wherein, the molar ratio of the main catalyst and the co-catalyst is 3.11 in terms of Ti / Al. Reaction flow see figure 1 .

[0107] The mass flow rate of mixed liquid I is 1.7t / h, accounting for 0.37% of the mass flow rate of stream II. In the mixed liquid I, the alkane n-hexane content accounts for 25% by weight of the mixed liquid (the molar content is 25%), and the olefin content accounts for 75% by weight of the mixed liquid (the molar content is 75%), wherein the ethylene content accounts for 7.8% by weight of the mixed liquid. % by weight (23.8% in molar content), the content of 1-octene accounts for 67.2% by weight (51.2% in molar content) of the mixed liquid, and the mixed liquid also contains 180ppm of triethylaluminum cocatalyst.

[0108] The superficial fluidization ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com