Preparation method of photocuring type superhydrophobic composite film

A composite membrane and super-hydrophobic technology, applied in the coating and other directions, can solve the problems of unfavorable promotion and implementation, high cost of preparation process, and high requirements for process accuracy, and achieve good hydrophobic effect, simple operation process, and enhanced anti-detachment strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

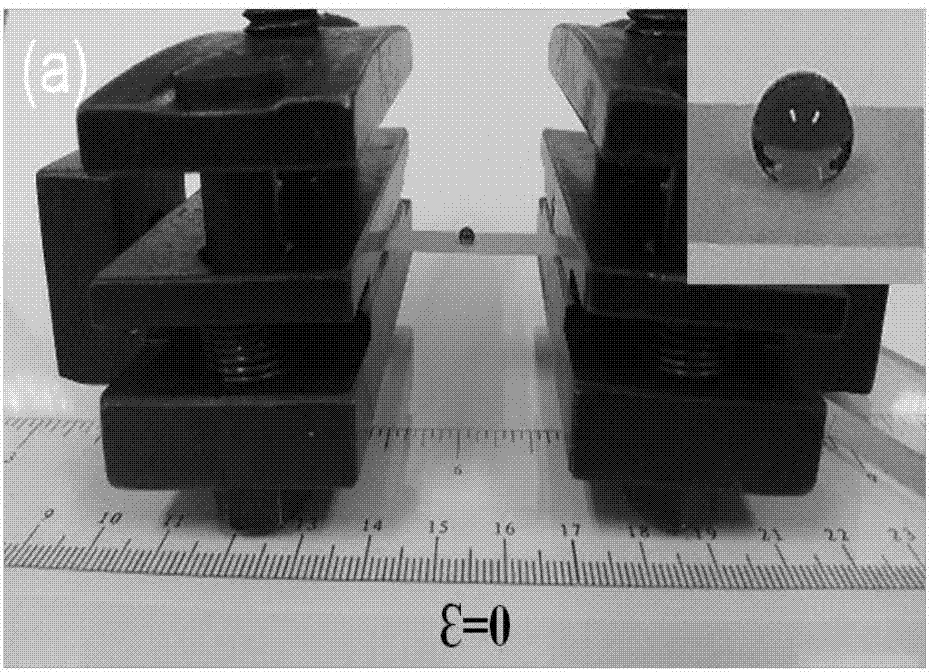

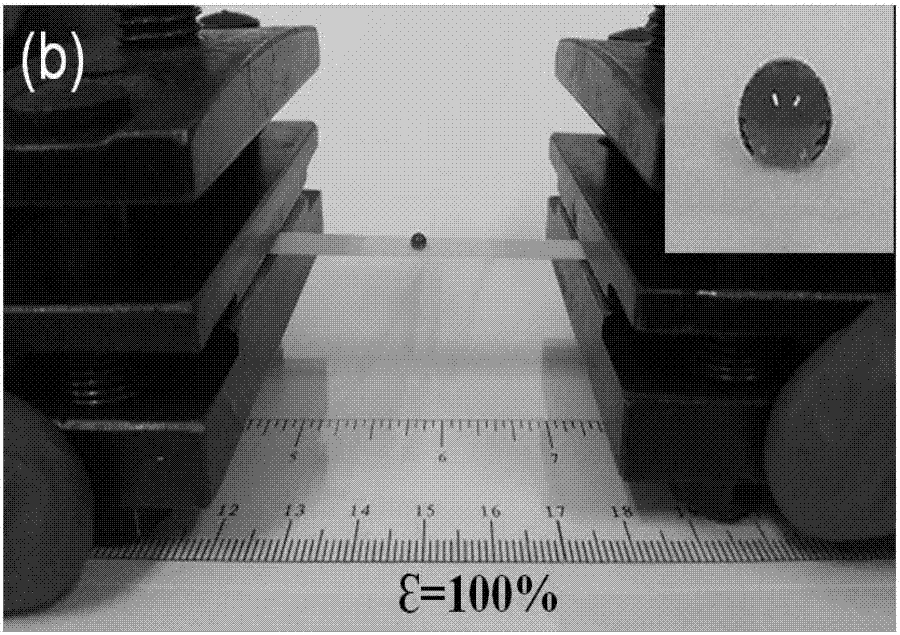

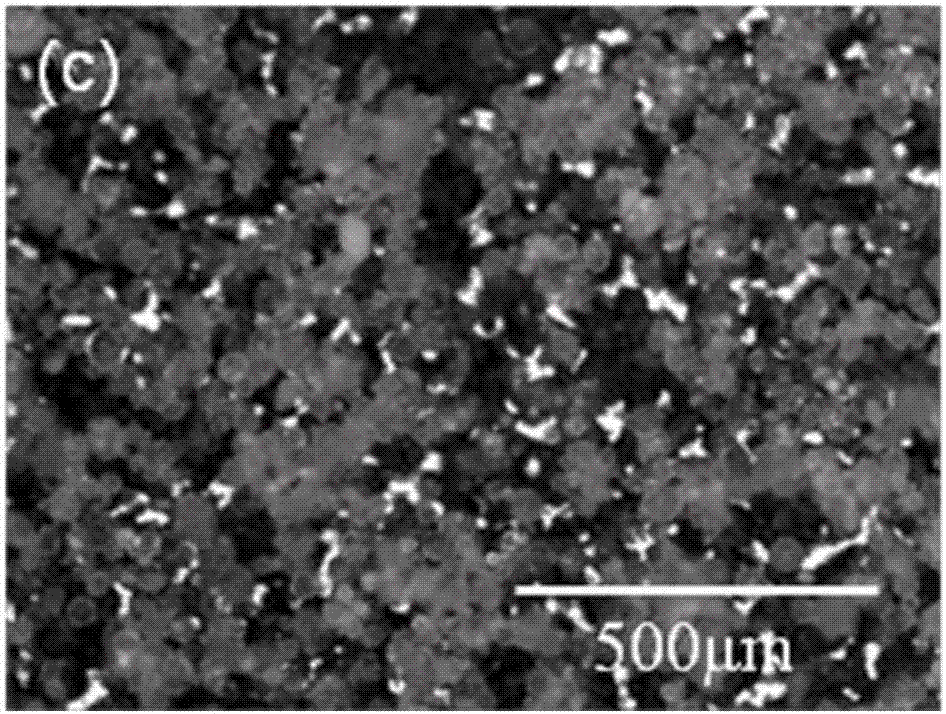

[0042] Urethane acrylate prepolymer and photoinitiator 1173 were weighed according to the mass ratio of 98:2, after stirring and ultrasonic (5min) mixing evenly, poured into the tetrafluoroethylene mold, at 223mW / cm 2 The pre-cured elastic substrate was prepared by irradiating under ultraviolet light for 1 s. Weigh the silicone rubber, mercaptosiloxane, and photoinitiator 1173 according to a certain mass ratio, add a certain amount of n-hexane, stir and dissolve to make a solution, then add a certain amount of hydrophobic nano-silica, and ultrasonicate for 30 minutes after stirring. Prepare a suspension; the mass fractions of silicone rubber, mercapto silicone, photoinitiator, silicon dioxide and n-hexane in the suspension are: 5%, 0.6%, 0.05%, 4%, 90.35%, respectively. The suspension was sprayed on the pre-cured elastic substrate and irradiated with ultraviolet light for 30 s to prepare a superhydrophobic elastic composite film.

Embodiment 2

[0044] Urethane acrylate prepolymer and photoinitiator 184 were weighed according to the mass ratio of 95:5, after stirring and ultrasonic (5min) mixing evenly, poured into the tetrafluoroethylene mold, at 223mW / cm 2 The pre-cured elastic substrate was prepared by irradiating with ultraviolet light for 20s. Weigh the silicone rubber, mercaptosiloxane, and photoinitiator 1173 according to a certain mass ratio, add a certain amount of n-hexane, stir and dissolve to make a solution, then add a certain amount of hydrophobic nano-silica, and ultrasonicate for 30 minutes after stirring. Prepare a suspension; the mass fractions of silicone rubber, mercapto silicone, photoinitiator, silicon dioxide and n-hexane in the suspension are: 5%, 0.8%, 0.05%, 3.8%, and 90.35%, respectively. The suspension was sprayed on the pre-cured elastic substrate and irradiated with ultraviolet light for 50 s to prepare a superhydrophobic elastic composite film.

Embodiment 3

[0046] Urethane acrylate prepolymer and photoinitiator TPO were weighed according to the mass ratio of 97:3, after stirring and ultrasonic (5min) mixing evenly, poured into the tetrafluoroethylene mold, at 223mW / cm 2 The pre-cured elastic substrate was prepared by irradiating under ultraviolet light for 1 s. Weigh silicone rubber, mercaptosiloxane, and photoinitiator 1173 according to a certain mass ratio, add a certain amount of n-hexane, stir and dissolve to make a solution, and then add a certain amount of hydrophobic micron and nanometer silica (1:1 ), stirred and ultrasonicated for 30 minutes to make a suspension; the mass fractions of silicone rubber, mercaptoorganosilicon, photoinitiator, silicon dioxide and n-hexane in this suspension were: 7%, 1.1%, 0.2%, respectively. 5.5%, 86.2%. The suspension was sprayed on the pre-cured elastic substrate and irradiated with ultraviolet light for 60 s to prepare a superhydrophobic elastic composite film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com