A kind of electromagnetic shielding film and preparation method thereof

A technology of electromagnetic shielding film and conductive adhesive, applied in the fields of magnetic field/electric field shielding, electrical components, conductive adhesives, etc., can solve the problems of heavy metal pollution, unable to meet the requirements of ultra-high frequency signal shielding, poor reliability and heat resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

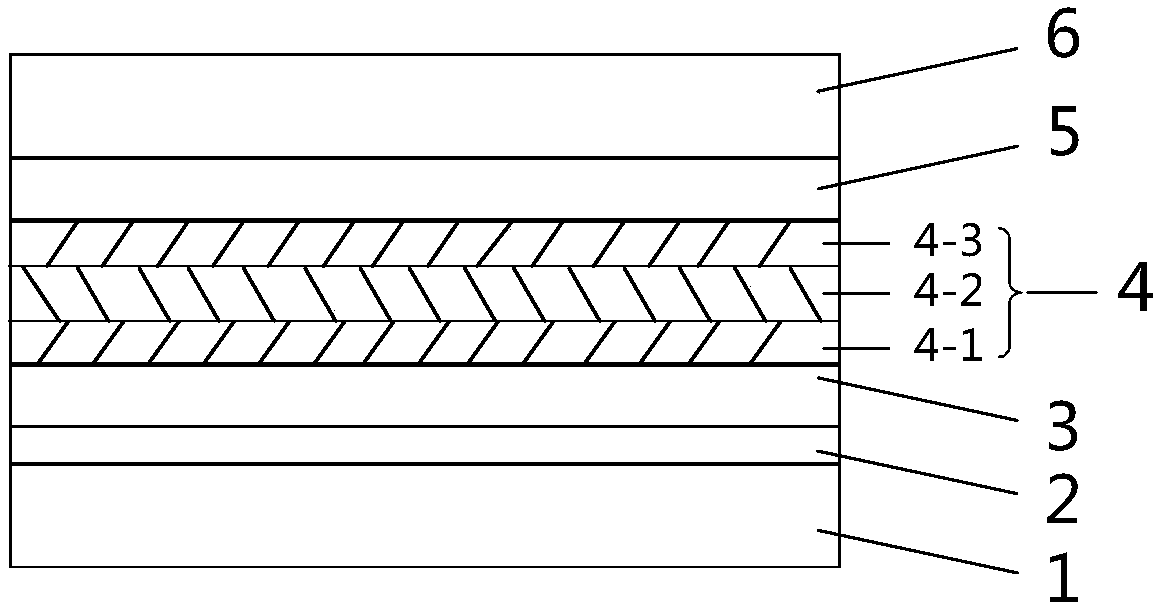

[0073] The present invention also provides a preparation method of the electromagnetic shielding film described in the above technical solution, comprising the following steps:

[0074] a) coating a release liquid on the surface of the carrier layer and drying to form a release layer;

[0075] b) coating an insulating material on the surface of the release layer and drying to form an insulating layer;

[0076] c) sequentially sputtering a metal bottom layer on the surface of the insulating layer, evaporating a metal functional layer, and sputtering a metal protective layer to form a metal layer;

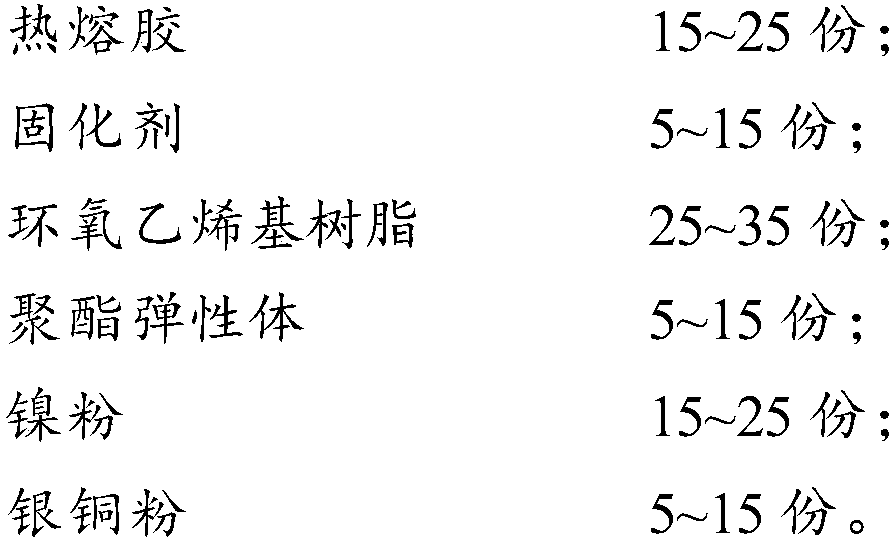

[0077] d) coating conductive glue on the surface of the metal layer to form a conductive glue layer;

[0078] e) Attaching a protective film on the surface of the conductive adhesive layer to form a protective film layer.

[0079] Wherein, the types, thicknesses and sources of the carrier layer, the release layer, the insulating layer, the metal layer, the conductive adhesive layer...

Embodiment 1

[0091] 1) Provide a roll of PET film with a thickness of 50 μm and a width of 550 mm (length 200 meters), and use a comma knife coater to coat the release liquid on the surface of the PET roll film to form a coating with a thickness of less than 1 μm , bake and dry at 150°C for 3 minutes to form a release layer;

[0092] Preparation of the release liquid used: Mix 30 parts of HDPE plastic pellets with 70 parts of PMA solvent and grind them into nano-scale by a mill to form a release liquid;

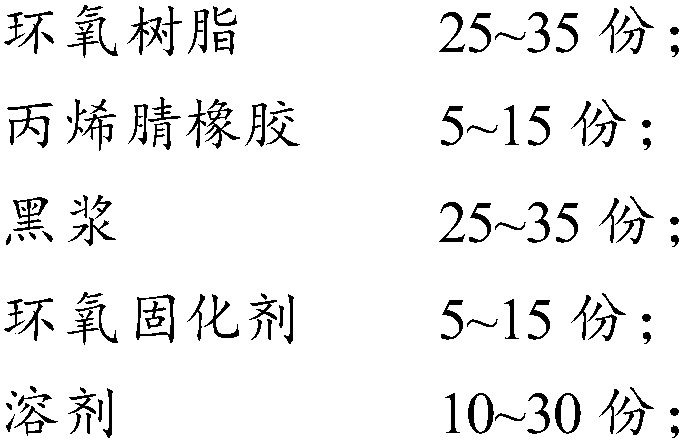

[0093] 2) Coat the insulating material on the surface of the release layer by using a comma scraper coating method, control the thickness of the insulating material between 2 and 10 μm, and form an insulating layer after drying;

[0094] Preparation of insulating materials used: 30 parts of E-44 epoxy resin (provided by Jinan Baorui Resin Chemical Co., Ltd.), 10 parts of acrylonitrile rubber (provided by Shandong Zixiang Chemical Industry Co., Ltd.), 8501 black paste (provided by Risheng ...

Embodiment 2

[0100] 1) Provide a roll of PET film with a thickness of 75 μm and a width of 550 mm (length 200 meters), and use a comma knife coater to coat the release liquid on the surface of the PET roll film to form a coating with a thickness of less than 1 μm , bake and dry at 160°C for 2 minutes to form a release layer;

[0101] Preparation of the release liquid used: Mix 30 parts of HDPE plastic pellets with 70 parts of PMA solvent and grind them into nano-scale by a mill to form a release liquid;

[0102] 2) Coat the insulating material on the surface of the release layer by using a comma scraper coating method, control the thickness of the insulating material between 2 and 10 μm, and form an insulating layer after drying;

[0103] Preparation of insulating materials used: 70 parts of PI ink (provided by Huizhou Jiaqi Coating Co., Ltd.) with model number F8812, 2 parts of PI906 epoxy curing agent (provided by Huizhou Jiaqi Coating Co., Ltd.) and 28 parts of 8501 black paste parts, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com