A method for the directional preparation of low-viscosity and ultra-low-viscosity alginate by enzymatic method based on ion regulation

An ultra-low viscosity, alginate technology, applied in chemical recovery, fermentation and other directions, can solve the problems of water consumption, poor molecular weight uniformity, etc., and achieve the effect of simple process, strong continuity and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Raw material pretreatment: take 100kg of dried kelp and soak in 1000L of water to remove impurities, then fix the color in 100L of 0.5% formaldehyde solution for 2 hours, and then wash off the surface formaldehyde with water;

[0032] (2) Digestion: Digest the raw material in 2000L of 6% sodium bicarbonate solution for 3.5 hours at 60°C with stirring;

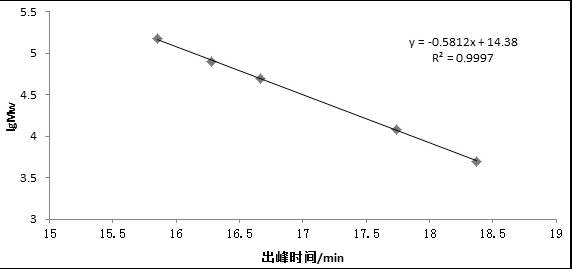

[0033] (3) Regulation of enzyme activity: KCl, NaCl and BaCl 2 Add the solution to the crude enzyme solution of alginate lyase so that the final concentrations are 150mmol / L, 500mmol / L and 5mmol / L respectively, and incubate at a constant temperature of 30°C for 20min, so as to realize the synthesis of the three monomeric enzymes of alginate lyase Enzyme activity regulation.

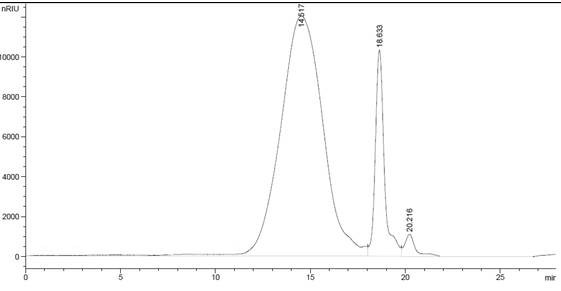

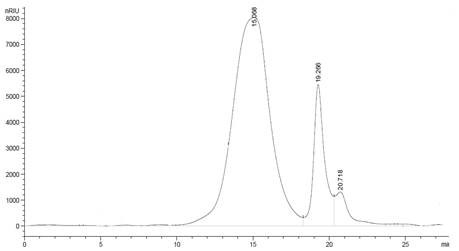

[0034] (4) Enzyme hydrolysis and filtration: Add 2000L of water to the alkali-treated digestive solution for preliminary dilution, add 10% hydrochloric acid after cooling to room temperature to adjust the pH to 6, and place them in membrane bio...

Embodiment 2

[0040] (1) Raw material pretreatment: Soak 30kg of dried macroalgae in 300L of water for 3 hours to remove impurities, fix the color in 30L of 0.5% formaldehyde solution for 4 hours, and wash off the surface formaldehyde with water;

[0041] (2) Digestion: Digest the raw material in 450L of 6% sodium bicarbonate solution for 2 hours at 65°C with stirring;

[0042] (3) Regulation of enzyme activity: KCl, NaCl and BaCl 2 Add the solution to the crude enzyme solution of alginate lyase so that the final concentrations are 200mmol / L, 450mmol / L and 2.5mmol / L respectively, and incubate at a constant temperature of 30°C for 30min, so as to realize the three monomeric enzymes of alginate lyase Control enzyme activity.

[0043] (4) Enzymolysis: Add 300L of water to the alkali-treated digestive solution for initial dilution, add 10% hydrochloric acid after cooling to room temperature to adjust the pH to 7, place them in membrane bioreactors with a molecular weight cut-off of 40kDa, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com