Polyether-ether-ketone modified composite material and manufacturing method thereof

A composite material and polyether ether ketone technology, which is applied in the field of polyether ether ketone modified composite material and its manufacture, can solve the problem of high cost of pure polyether ether ketone material, unattainable temperature resistance and wear resistance, and narrow application range. and other problems, to achieve the effect of improving tensile strength, improving heat aging resistance and tensile strength, and expanding application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

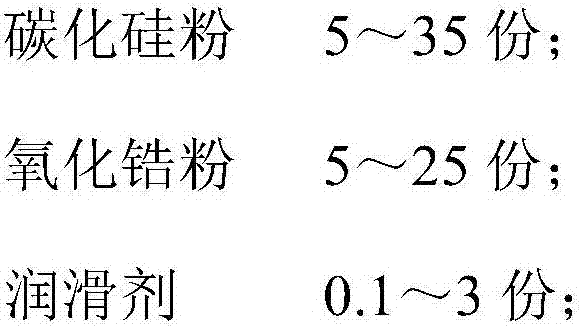

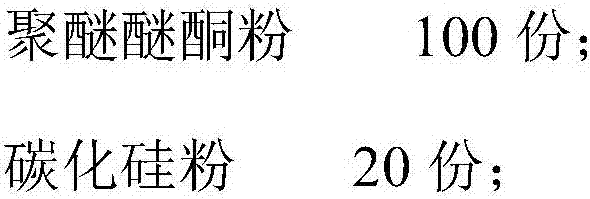

[0026] Embodiment 1 Polyetheretherketone modified composite material includes the following components in parts by mass:

[0027]

[0028]

[0029] The melt viscosity of the polyetheretherketone powder was randomly measured to be 100 Pa·s.

[0030] Embodiment 1 Preparation method of polyether ether ketone modified composite material:

[0031] §1 Drying: put the polyether ether ketone powder, the silicon carbide powder, and the zirconia powder into a dehumidification drying box and dry at 160°C for 4 hours;

[0032] §2 Mixing: Put the dried polyether ether ketone powder, the dried silicon carbide powder, the dried zirconia powder and the lubricant polysiloxane into a high-mixer in sequence, First mix at a low speed for 1 minute, then mix at a high speed for 15 minutes at a temperature of 105°C, and then discharge to obtain a mixed ingredient;

[0033] §3 Extrusion molding: Pass the mixed ingredients through a twin-screw extruder, melt extrude, and cool to obtain a produ...

Embodiment 2

[0035] Example Dipolyether ether ketone modified composite material, including the following components in parts by mass:

[0036]

[0037] The melt viscosity of the polyetheretherketone powder was randomly measured to be 605 Pa·s.

[0038] The preparation method of embodiment dipolyether ether ketone modified composite material:

[0039] §1 Drying: put the polyether ether ketone powder, the silicon carbide powder, and the zirconia powder into a dehumidification drying box and dry at 160°C for 4 hours;

[0040] §2 Mixing: Put the dried polyether ether ketone powder, the dried silicon carbide powder, the dried zirconia powder and the lubricant polysiloxane into a high-mixer in sequence, First mix at a low speed for 1 minute, then mix at a high speed for 20 minutes at a temperature of 115°C, and then discharge to obtain a mixed ingredient;

[0041] §3 Extrusion molding: Pass the mixed ingredients through a twin-screw extruder, melt extrude, and cool to obtain a product. In...

Embodiment 3

[0043] Example Tripolyetheretherketone modified composite material, including the following components in parts by mass:

[0044]

[0045] The melt viscosity of the polyetheretherketone powder was randomly measured to be 300 Pa·s.

[0046] The preparation method of embodiment tripolyetheretherketone modified composite material:

[0047] §1 Drying: put the polyether ether ketone powder, the silicon carbide powder, and the zirconia powder into a dehumidification drying box and dry at 160°C for 4 hours;

[0048] §2 Mixing: Put the dried polyether ether ketone powder, the dried silicon carbide powder, the dried zirconia powder and the lubricant polysiloxane into a high-mixer in sequence, First mix at a low speed for 1 minute, then mix at a high speed for 15 minutes at a temperature of 110°C, and then discharge to obtain a mixed ingredient;

[0049] §3 Extrusion molding: Pass the mixed ingredients through a twin-screw extruder, melt extrude, and cool to obtain a product. In t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Degree of sulfonation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com