Production method of high-performance aluminum alloy rod

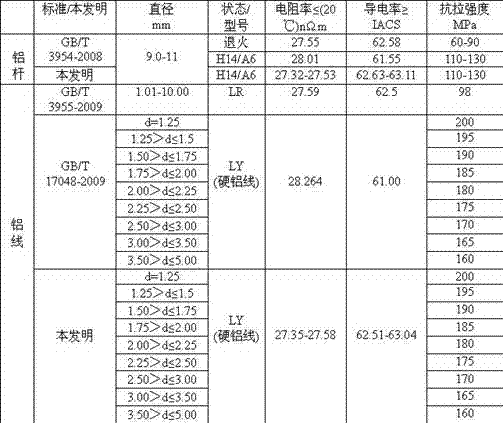

A technology for aluminum alloy rods and production methods, applied in the direction of conductive materials, conductive materials, cable/conductor manufacturing, etc., can solve the problems of high wire construction and operation requirements, affecting aluminum alloy cables, failing to meet the index requirements, etc., to achieve The effect of improving mechanical properties, simplifying the production process, increasing production efficiency and qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] Embodiment: a kind of production method of high-performance aluminum alloy rod, comprises the following steps:

[0029] Step 1. Use Al99.70 and Al99.85 remelted aluminum ingots in combination, put them into an aluminum melting furnace for smelting, and control the temperature of the molten aluminum in the furnace to ≤760°C, where Al99.70 aluminum ingots account for 20-40%, and Al99. The proportion of 85 aluminum ingots is 60~80%;

[0030] Step 2. Transfer the smelted aluminum liquid obtained in step 1 to the holding furnace, stir evenly, and then take samples for rapid analysis with a direct-reading spectrometer to detect the contents of Al, Si, Fe, Mn, Cr, Ti, and V in the solution;

[0031] Step 3: Add aluminum-boron master alloy and aluminum-cerium rare-earth master alloy to the molten aluminum after smelting, control the temperature of the molten aluminum in the holding furnace at 740±10°C, stir manually and electromagnetically for 20 minutes, and obtain alloy alumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com