Method of manufacturing single-phase Sm2Co17 nanocrystalline block body material

A technology of bulk materials and nanocrystals, applied in polycrystalline material growth, crystal growth, single crystal growth, etc., can solve the problems of few research reports on nanocrystal bulk materials, and achieve strong controllability of technical parameters, The grain boundary area is pure and free, and the effect of inhibiting long-range diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

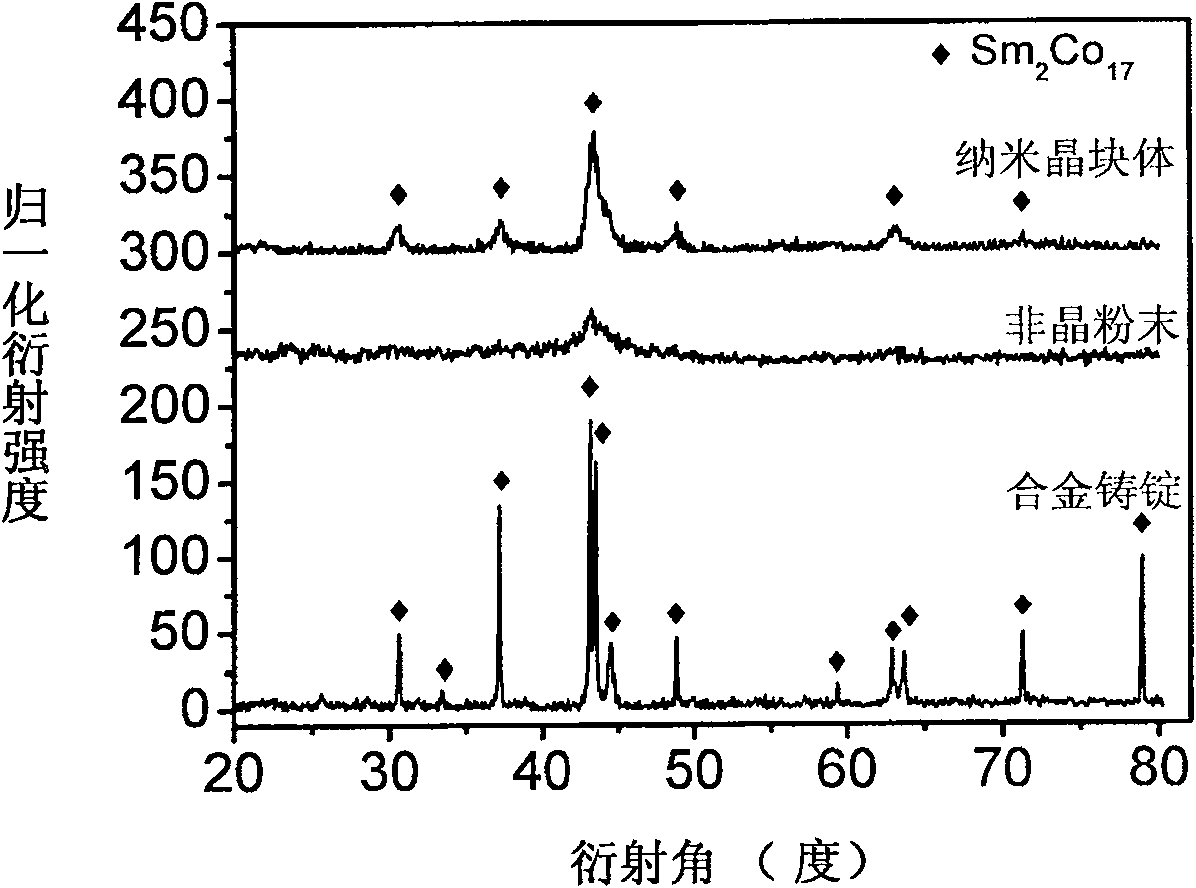

[0023] 1) Mix the small metal Sm and Co according to the mass ratio of 23.1%:76.9%, so that the Co raw material is wrapped around the Sm raw material. CuCr25 alloy prepared by smelting method", High Voltage Apparatus, No. 37, Volume 2, Page 14) the same vacuum induction melting procedure to prepare Sm 2 co 17 Alloy ingots, the alloy ingots are remelted twice;

[0024] 2) Put Sm 2 co 17 The alloy ingot is crushed and ground into powder particles smaller than 500 μm, and the powder particles are put into a ball mill pot according to the ratio of ball to material mass ratio of 10:1, and ball milled for 20 hours to obtain a completely amorphous alloy powder;

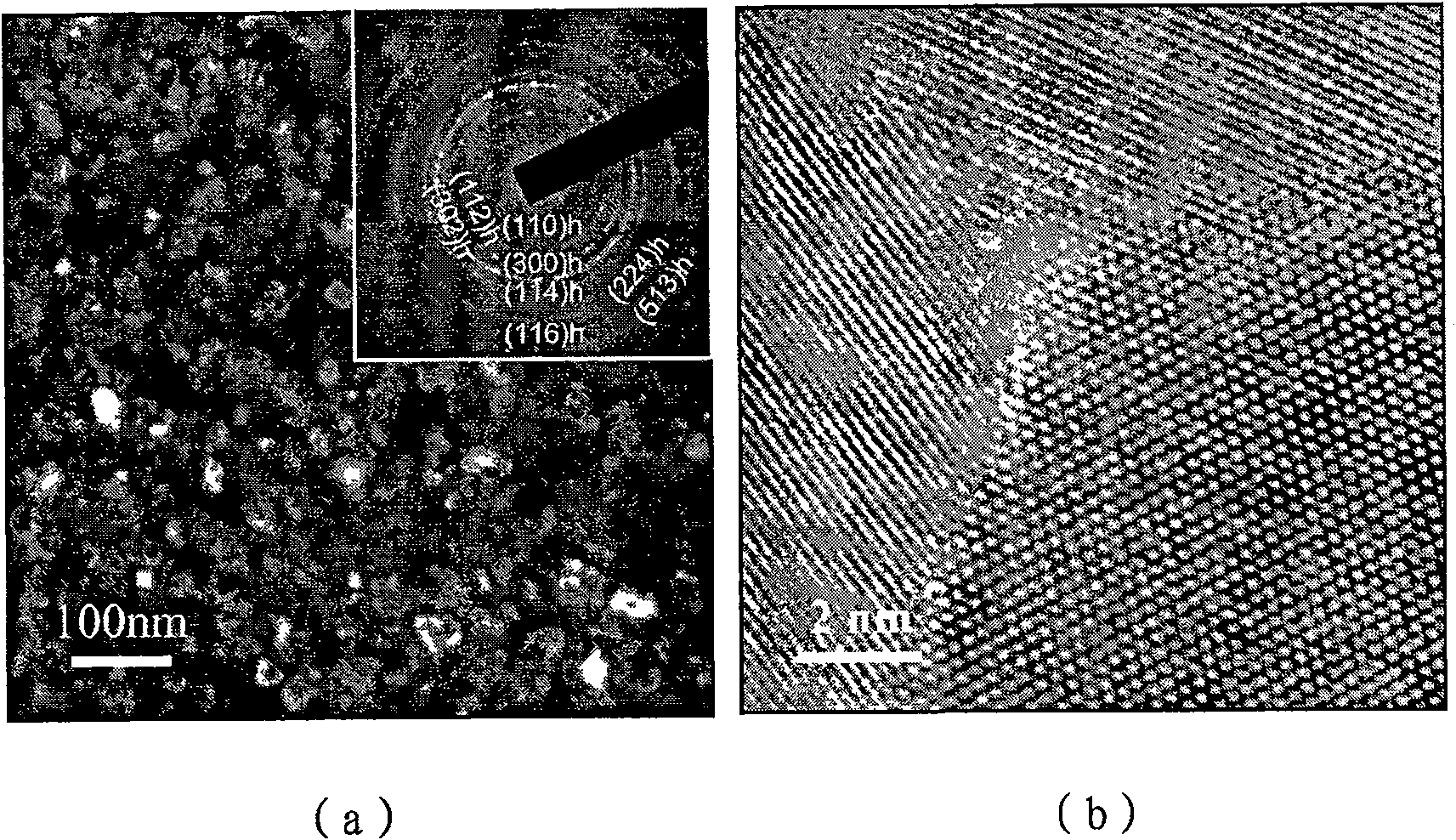

[0025] 3) Put the amorphous alloy powder into the cemented carbide mold under the protection of argon and cold press it into the spark plasma sintering equipment for sintering and densification. The following process parameters are adopted: the final sintering temperature is 700°C, The speed is 50°C / min, the sintering pr...

Embodiment 2

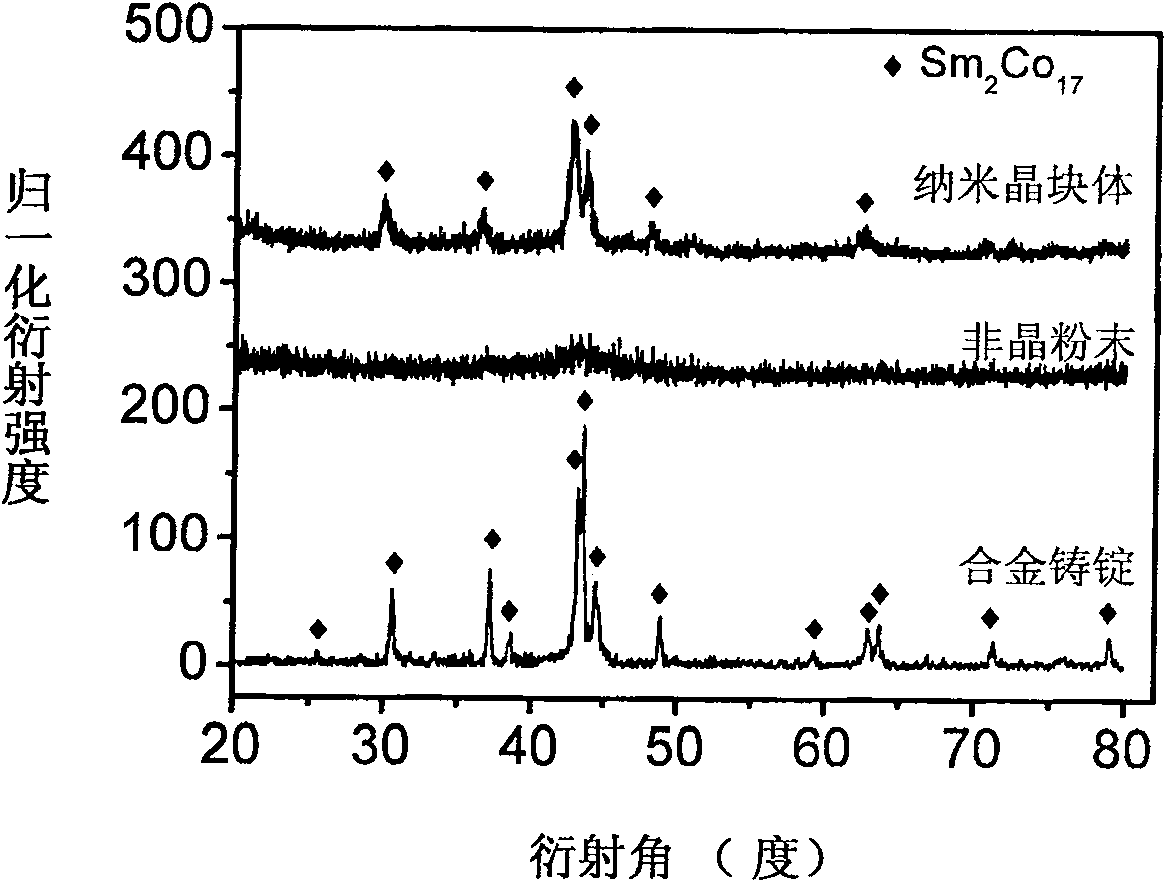

[0028] 1) Mix the small metal Sm and Co according to the mass ratio of 23.1%:76.9%, so that the Co raw material is wrapped around the Sm raw material. CuCr25 alloy prepared by smelting method", High Voltage Apparatus, No. 37, Volume 2, Page 14) the same vacuum induction melting procedure to prepare Sm 2 co 17 Alloy ingots, the alloy ingots are remelted three times;

[0029] 2) Put Sm 2 co 17 The alloy ingot is crushed and ground into powder particles smaller than 500 μm, and the powder particles are put into a ball mill jar according to the ratio of ball to material mass ratio of 20:1, and ball milled for 10 hours to obtain a completely amorphous alloy powder;

[0030] 3) Put the amorphous alloy powder into the cemented carbide mold under the protection of argon and cold press it into the spark plasma sintering equipment for sintering and densification. The following process parameters are adopted: the final sintering temperature is 800°C, The rate is 100°C / min, the sinter...

Embodiment 3

[0033] 1) Mix the small metal Sm and Co according to the mass ratio of 23.1%:76.9%, so that the Co raw material is wrapped around the Sm raw material. CuCr25 alloy prepared by smelting method", High Voltage Apparatus, No. 37, Volume 2, Page 14) the same vacuum induction melting procedure to prepare Sm 2 co 17 Alloy ingots, the alloy ingots are remelted 4 times;

[0034] 2) Put Sm 2 co 17 The alloy ingot is crushed and ground into powder particles smaller than 500 μm, and the powder particles are put into a ball mill pot according to the ratio of ball to material mass ratio of 12:1, and ball milled for 15 hours to obtain a completely amorphous alloy powder;

[0035] 3) Put the amorphous alloy powder into the cemented carbide mold under the protection of argon and cold press it into the spark plasma sintering equipment for sintering and densification. The following process parameters are adopted: the final sintering temperature is 750°C, The rate is 80°C / min, the sintering pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com