A preparation method of cemented carbide nano-particle size powder and high-performance sintered bulk material

A cemented carbide block and bulk material technology, applied in the field of new materials and new powder metallurgy, can solve the problems of uneven particle size distribution, many powder crystal defects, difficult to obtain nanocrystals, etc., to improve the densification rate and reduce the grain boundary. Distortion energy, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Violet tungsten (WO 2.72 ), micron-scale cobalt oxide (Co 3 o 4 ) and vanadium oxide (V 2 o 5 ) and graphene mixture as raw material, according to the requirements of Co content (Co content 10wt%) in the final prepared cemented carbide bulk material, the above raw materials are mixed in proportion and ball milled, the ball milling medium is deionized water, the ball milling speed 400r / min, the ball milling time is 150h, the ball-to-material ratio is 15:1, and the mixed powder after ball milling is dried in a vacuum drying oven.

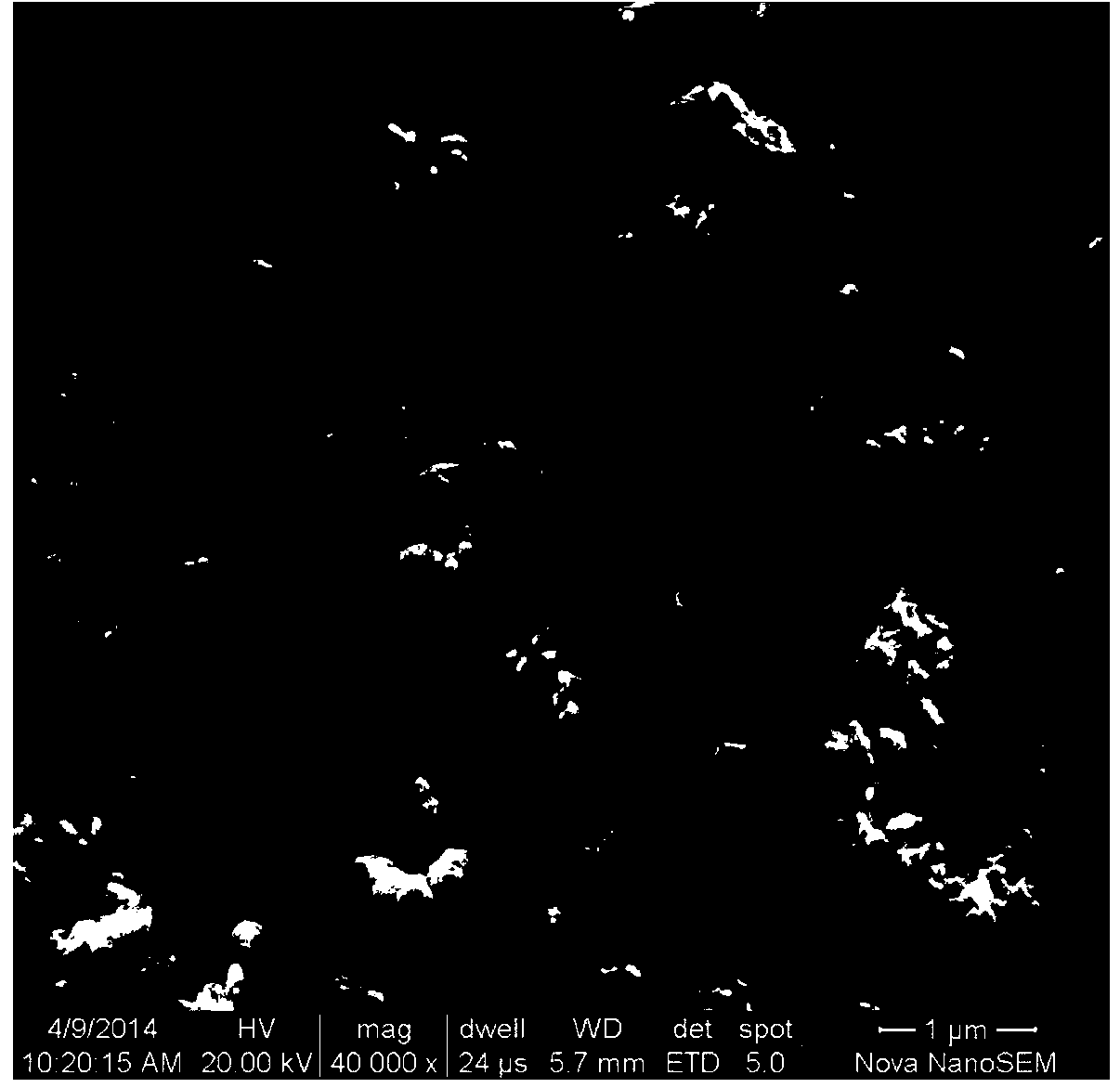

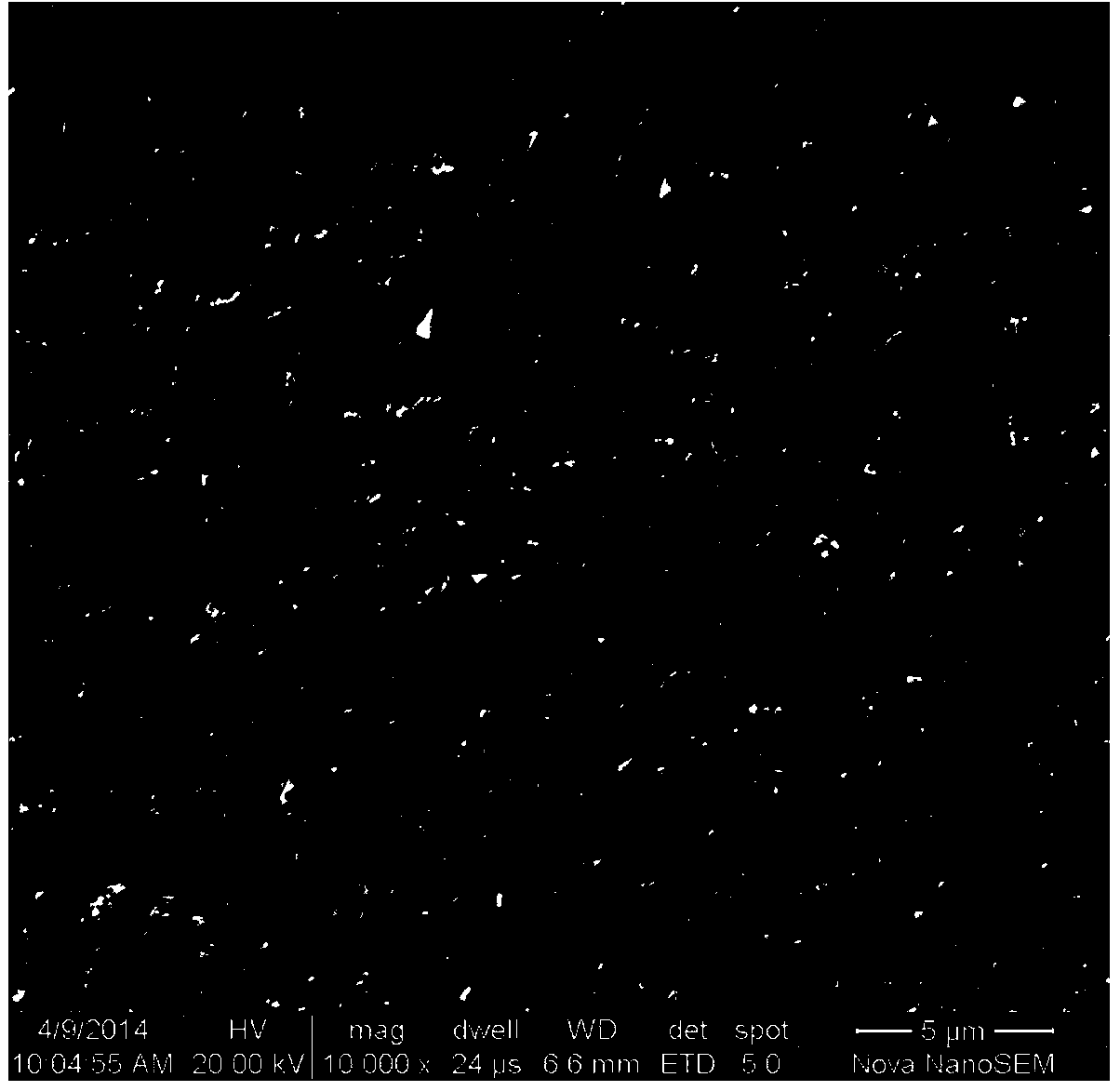

[0023] The mixed powder after ball mill drying was cold-pressed into a billet, and placed in a furnace with flowing argon for reduction and carbonization reactions. The reaction temperature was 850°C, the heating rate was 10°C / min, and the holding time was 3h. The particle size of WC-Co-VC powder particles, its morphology see figure 1 .

[0024] The WC-Co-VC (above V 2 o 5 The added amount of VC is all converted into VC, and the mass pe...

Embodiment 2

[0026] Violet tungsten (WO 2.72 ), micron-scale cobalt oxide (Co 3 o 4 ) and vanadium oxide (V 2 o 5 ) and carbon nanotubes as raw materials, according to the requirements of the Co content in the final prepared cemented carbide bulk material (Co content 12wt%), the above raw materials are mixed in proportion and ball milled, the ball milling medium is deionized water, ball milling The rotation speed is 500r / min, the ball milling time is 100h, the ball-to-material ratio is 10:1, and the mixed powder after ball milling is put into a vacuum drying oven for drying.

[0027] The mixed powder after ball mill drying was cold-pressed into a billet, and placed in a furnace with flowing argon for reduction and carbonization reactions. The reaction temperature was 900°C, the heating rate was 15°C / min, and the holding time was 2h. Particle size of WC-Co-VC powder particles.

[0028] The WC-Co-VC powder (above-mentioned V 2 o 5 The added amount of VC is all converted into VC, and t...

Embodiment 3

[0030] Violet tungsten (WO 2.72 ), micron-scale cobalt oxide (Co 3 o 4 ) and vanadium oxide (V 2 o 5 ) with graphene and carbon nanotubes as raw materials, according to the requirements of Co content in the final prepared cemented carbide bulk material (Co content 8wt%), the above raw materials are mixed in proportion and ball milled, and the ball milling medium is deionized water, the ball milling speed is 600r / min, the ball milling time is 50h, the ball-to-material ratio is 5:1, and the mixed powder after ball milling is put into a vacuum drying oven for drying.

[0031] The mixed powder after ball mill drying was cold-pressed into a billet, and placed in a furnace fed with flowing argon for reduction and carbonization reactions. The reaction temperature was 1000°C, the heating rate was 20°C / min, and the holding time was 1h. Particle size of WC-Co-VC powder particles.

[0032] The WC-Co-VC powder (above-mentioned V 2 o 5 The added amount of VC is all converted into VC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com