Method for preparing single-phase SmCo7 nanocrystalline alloy block material without doping elements

A technology of nanocrystalline alloys and bulk materials, which is applied in the field of preparation of single-phase SmCo7 nanocrystalline alloy bulk materials, can solve problems such as few research reports.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

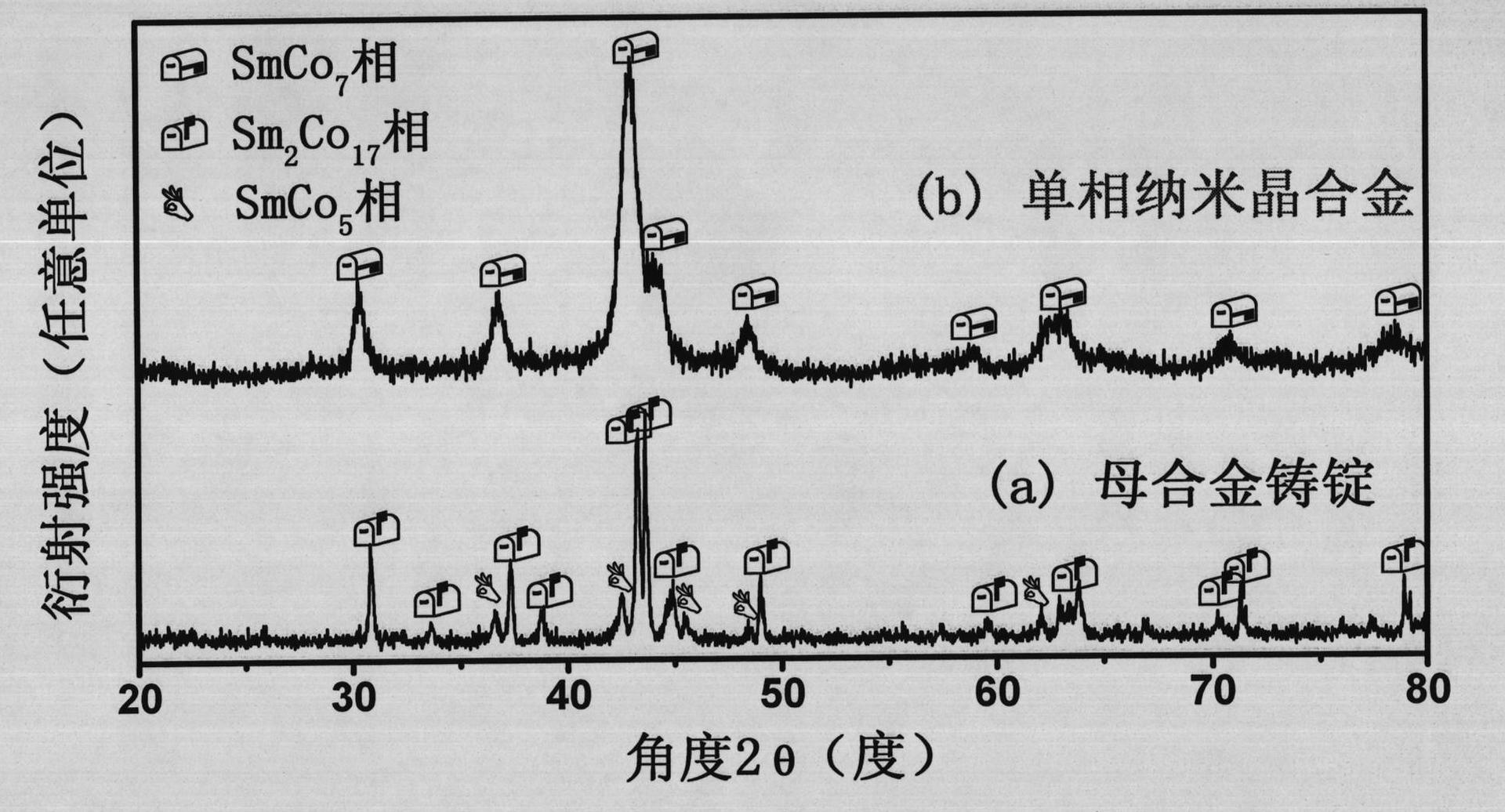

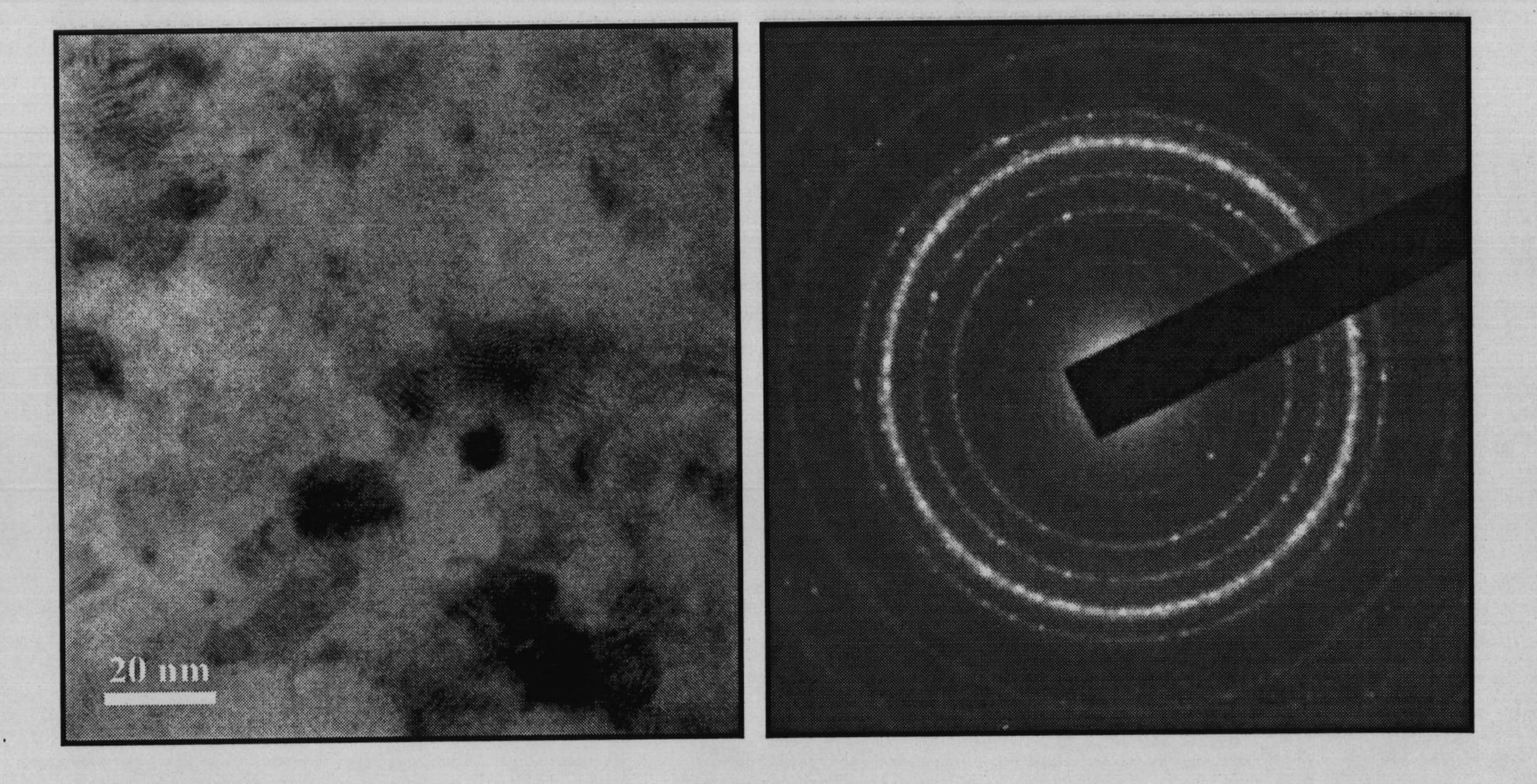

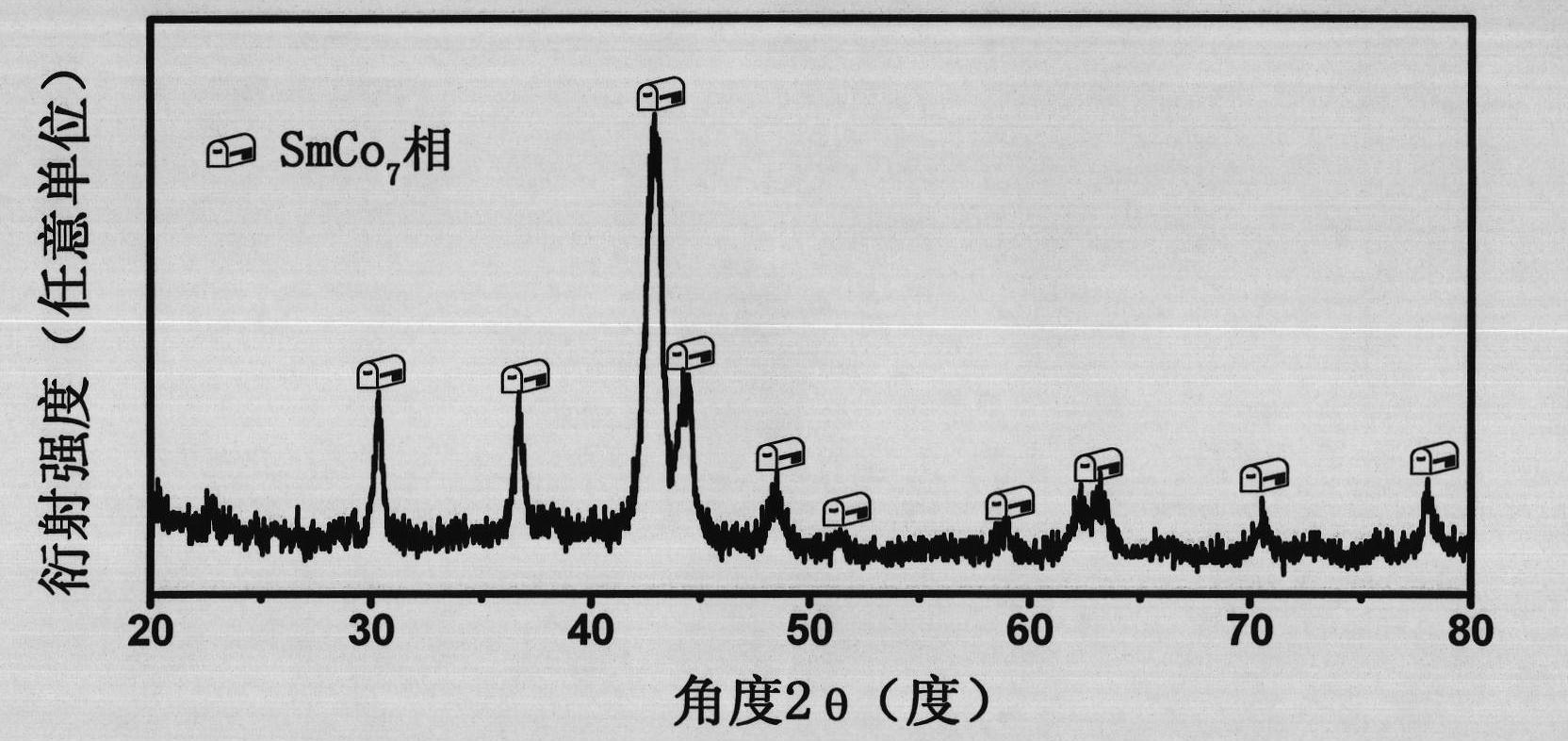

[0022] (1) Mix the metal Sm cut into thin strips and the granular metal Co powder according to the mass ratio of 26.7:73.3, put them into a mold and press them into a block, and put the block into a cold-wall magnetic levitation eddy current induction furnace. The nominal composition of SmCo was prepared by smelting in a copper crucible 7 The alloy ingot is remelted for more than 3 times, and the nominal composition is SmCo 7 master alloy ingot;

[0023] (2) Break the master alloy ingot into powder particles smaller than 500 μm, put the crushed powder particles into a ball mill tank according to the ball mass ratio of 25:1, the speed of ball milling is 400r / min, and the ball milling time is 25 hours , to obtain a completely amorphous alloy powder;

[0024] (3) The amorphous powder obtained by ball milling is put into a cemented carbide mold under the protection of argon and pre-pressed, and then sent to a spark plasma sintering equipment for sintering and densification. The ...

Embodiment 2

[0028] (1) Mix the metal Sm cut into thin strips and the granular metal Co powder according to the mass ratio of 26.7:73.3, put them into a mold and press them into a block, and put the block into a cold-wall magnetic levitation eddy current induction furnace. The nominal composition of SmCo was prepared by smelting in a copper crucible 7 The alloy ingot is remelted for more than 3 times, and the nominal composition is SmCo 7 master alloy ingot;

[0029] (2) Break the master alloy ingot into powder particles smaller than 500 μm, put the crushed powder particles into a ball mill tank according to the mass ratio of ball to material of 25:1, the speed of ball milling is 700r / min, and the ball milling time is 10 hours , to obtain a completely amorphous alloy powder;

[0030] (3) The amorphous powder obtained by ball milling is put into a cemented carbide mold under the protection of argon and pre-pressed, and then sent to a spark plasma sintering equipment for sintering and dens...

Embodiment 3

[0034] (1) Mix the metal Sm cut into thin strips and the granular metal Co powder according to the mass ratio of 26.7:73.3, put them into a mold and press them into a block, and put the block into a cold-wall magnetic levitation eddy current induction furnace. The nominal composition of SmCo was prepared by smelting in a copper crucible 7 The alloy ingot is remelted for more than 3 times, and the nominal composition is SmCo 7 master alloy ingot;

[0035] (2) Break the master alloy ingot into powder particles smaller than 500 μm, put the crushed powder particles into a ball mill tank according to the mass ratio of ball to material of 25:1, the speed of ball milling is 500r / min, and the ball milling time is 20 hours , to obtain a completely amorphous alloy powder;

[0036] (3) The amorphous powder obtained by ball milling is put into a cemented carbide mold under the protection of argon and pre-pressed, and then sent to a spark plasma sintering equipment for sintering and dens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com