Preparation of organic-inorganic composite solar cell based on perovskite-nano germanium particles

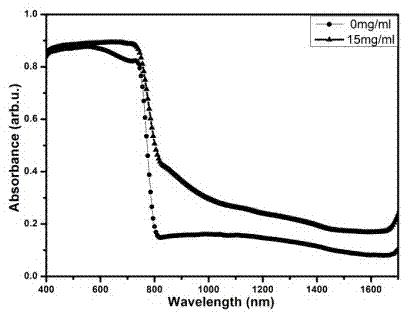

A solar cell, inorganic composite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problem of perovskite solar cells' poor long-wavelength light absorption coefficient capability, inability to effectively absorb and utilize long-wavelength sunlight, and inability to guarantee successful performance. The large-area uniformity of the film can be improved to improve the carrier transport capacity, realize large-scale industrial production, and improve the long-wave response range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

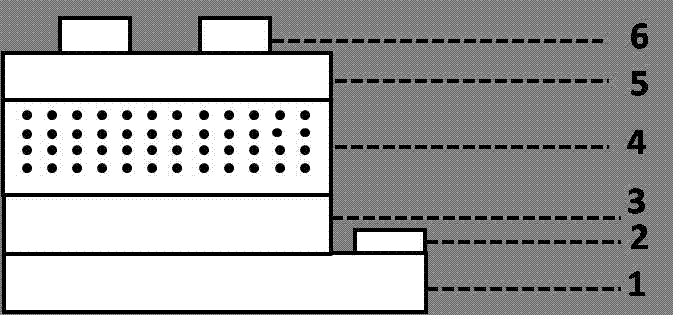

[0018] Such as figure 1 As shown, it is a schematic diagram of the battery structure obtained based on the preparation method of the perovskite-nano germanium particle organic-inorganic composite solar cell in the specific embodiment of the present invention, and the solar cell includes:

[0019] (1) Fluorine-doped tin dioxide (FTO) conductive glass 1;

[0020] (2) TiO 2 The electron transport layer 3 is spin-coated on the FTO conductive glass 1;

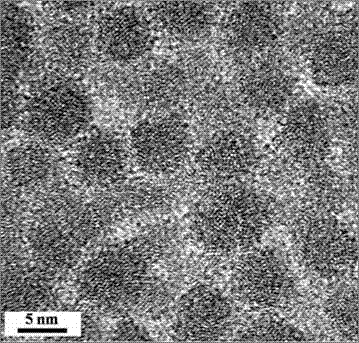

[0021] (3) Perovskite-nano-germanium particle composite active layer 4, ultrasonically sprayed on TiO 2 On the electron transport layer 3;

[0022] (4) P3HT organic polymer hole transport layer 5, spin-coated on the perovskite-nano-germanium particle composite active layer 4;

[0023] (5) The metal electrodes 2 and 6 are deposited on the FTO conductive glass 1 and the hole transport layer 5 respectively.

[0024] The specific preparation and preparation process of an organic-inorganic composite solar cell device based on perovs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com