A Spectral Beam Combining Device Using a Reflective Film-Coated Transmission Grating to Realize Two Diffractions

A technology of transmission grating and reflective film coating, which is applied in the direction of laser devices, semiconductor laser devices, devices for controlling laser output parameters, etc., can solve the problems of increasing adjustment accuracy and difficulty, reducing beam combining efficiency, increasing crosstalk, etc., and achieves compact structure and stability, increase beam combining efficiency, increase the effect of diffraction ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

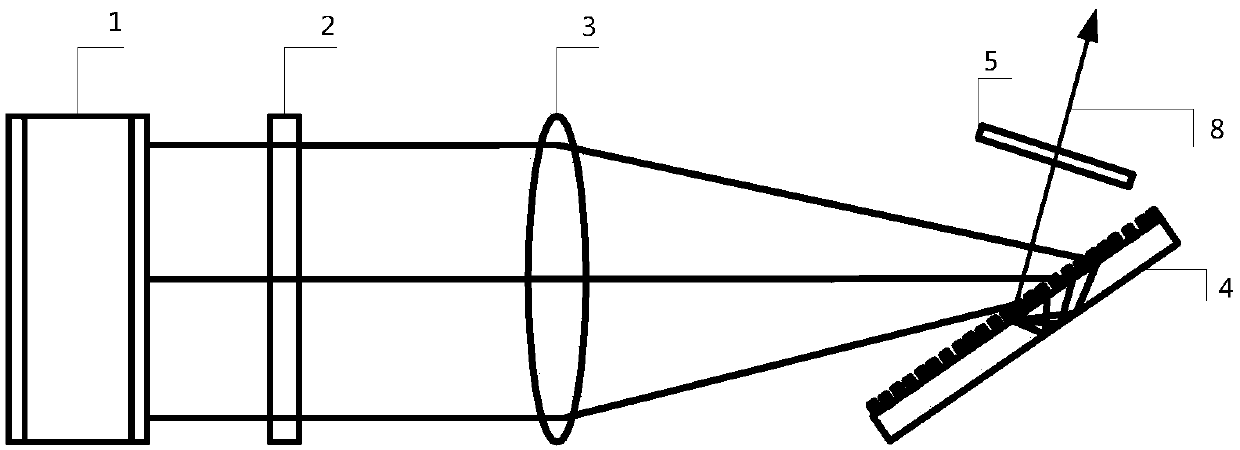

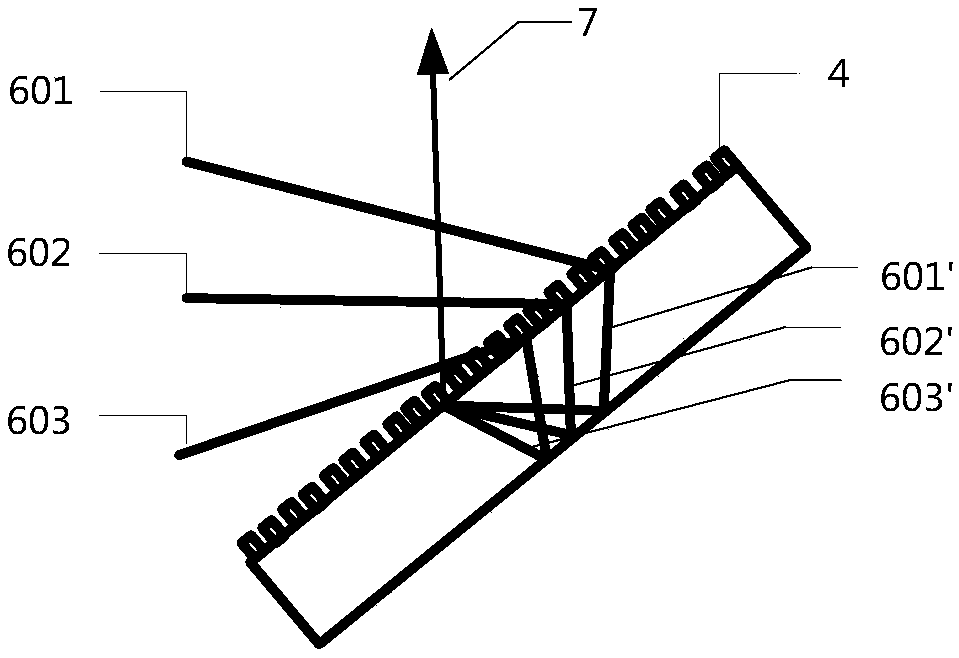

[0032] The present invention utilizes the grating and the reflector to realize the spectral beam combining device of two times of diffraction compressed spectral width. The specific realization process is as follows:

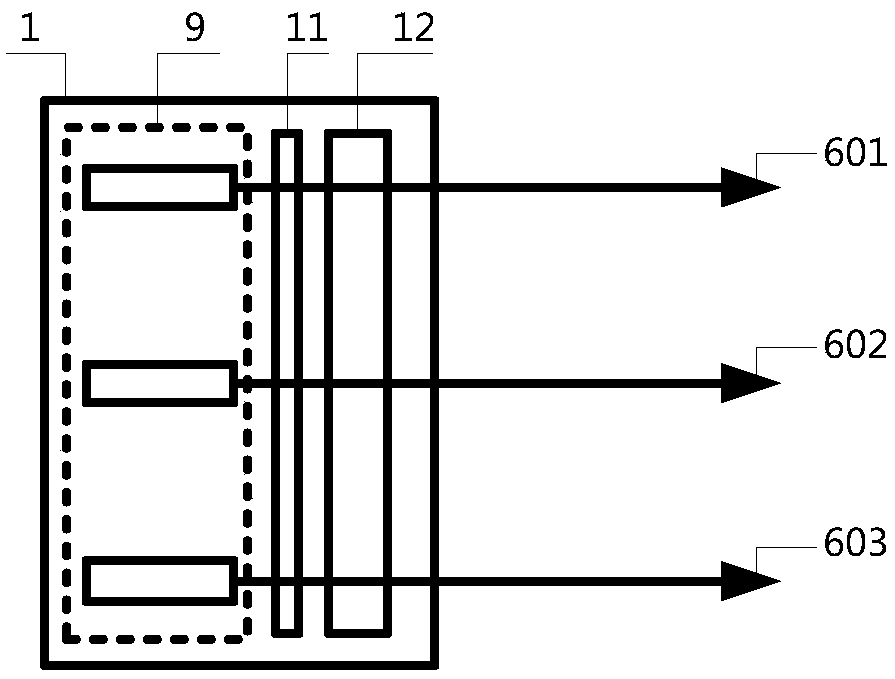

[0033]The central wavelength of the semiconductor laser light source 1 is 940nm, including 19 light-emitting units. The fast-axis divergence angle of a single light-emitting point beam is 35°, and the slow-axis divergence angle is 7°. The divergence angle of the fast axis is compressed to about 0.5° after the cylindrical lens array 13, and the divergence angle of the slow axis is compressed to about 4° after passing through the slow axis collimating cylindrical lens 2. The front cavity of the laser array is coated with an anti-reflection film, and the reflectivity of the cavity surface is less than 0.5%. The back cavity is coated with a high-reflection film, and the reflectivity of the cavity surface is greater than 99%.

[0034] Assuming that the diffraction or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com