A processing method and system for laser-induced graphene micro-nano structure

A technology of laser induction and processing method, which is applied in the direction of chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of unsatisfactory processing accuracy and failure to break through the diffraction limit of processing beams, so as to facilitate rapid processing, High-precision and high-resolution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

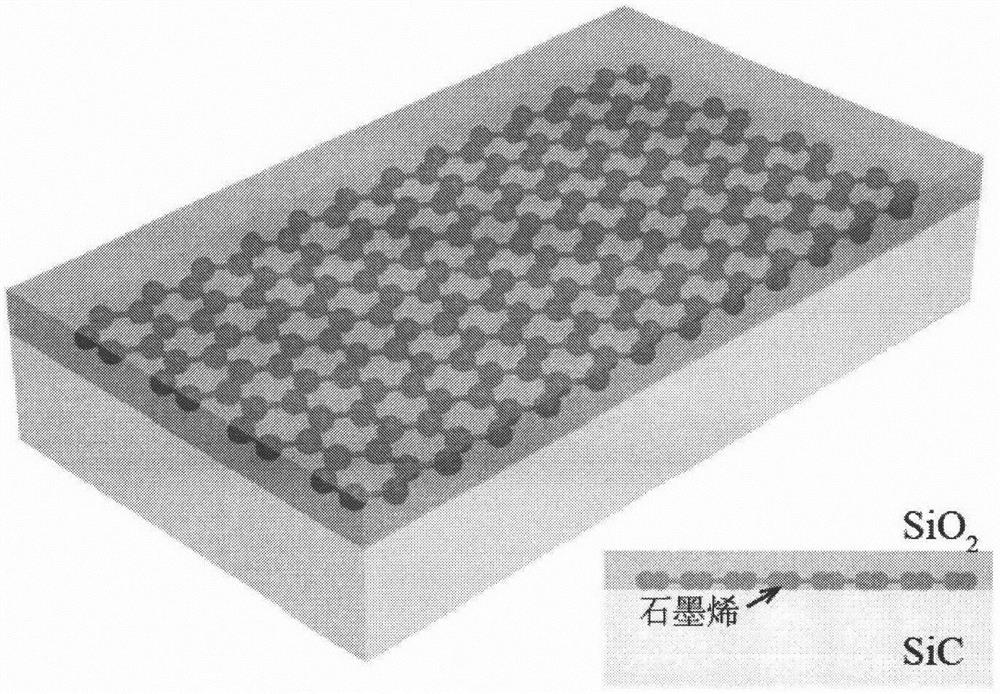

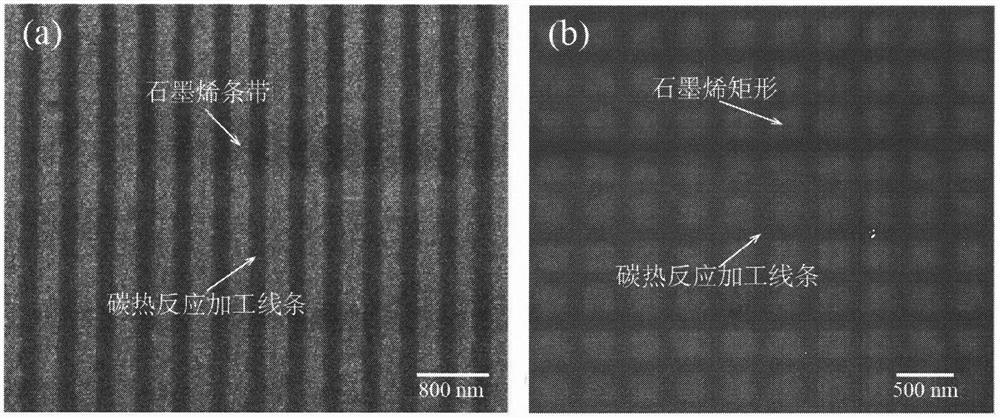

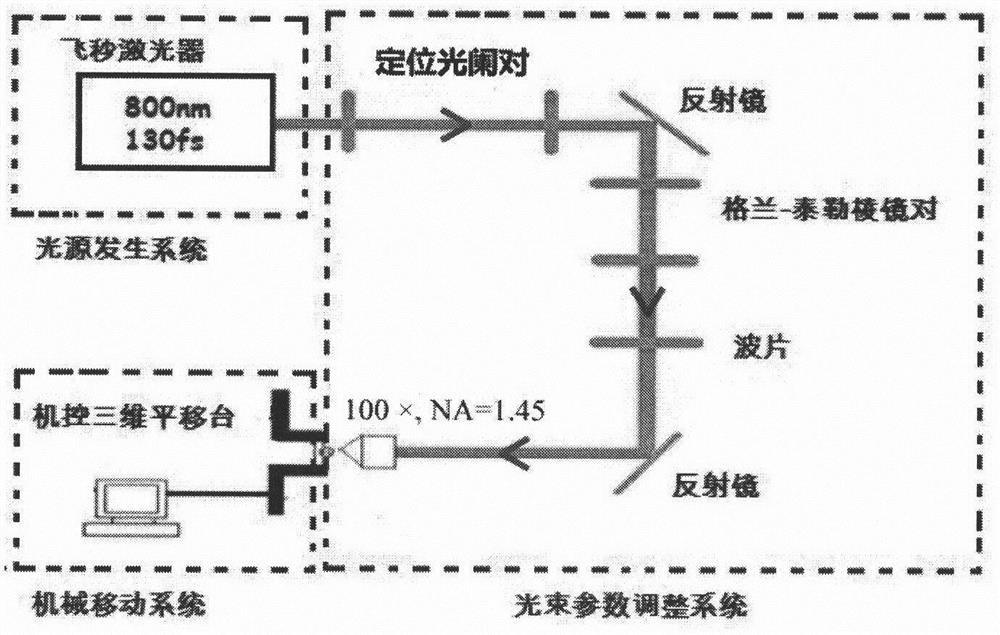

[0035] For the present invention, adopt wavelength 800nm, repeat frequency 1000Hz, the blue titanium sapphire femtosecond laser system of pulse width 130fs; Adopt the microscopic objective lens focusing that magnification is 100 times, numerical aperture 1.45; On machine-controlled precise three-dimensional translation platform; The oxide-graphene-substrate material sandwich structure sample is processed with a one-dimensional grid structure and a two-dimensional rectangular structure; the specific optical path diagram is as follows image 3 As shown, the ultrashort laser pulse emitted by the femtosecond laser first passes through two positioning apertures to block stray light and ensure the propagation direction of the beam. After changing the propagation direction through the reflector, it passes through a pair of Glan-Taylor prisms. By adjusting the angle between the crystal axes of the two Glan-Taylor prisms, the transmitted laser power can be accurately adjusted in real ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com