Preparation method of high-hardness wear-resistant super-hydrophobic concrete

A super-hydrophobic, high-hardness technology, applied in the manufacture of tools, ceramic molding machines, etc., can solve the problems of easy adhesion of microorganisms, poor freeze-thaw resistance, and easy corrosion of steel bars, and achieve simple process steps, improved hardness and wear resistance performance, excellent anti-icing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Take 50g of PO42.5 ordinary Portland cement, 50g of fine sand, 25ml of water, and 0.3g of fluorosilane, put them in a mixer and stir for 60min at a stirring speed of 250r / min to form cement slurry.

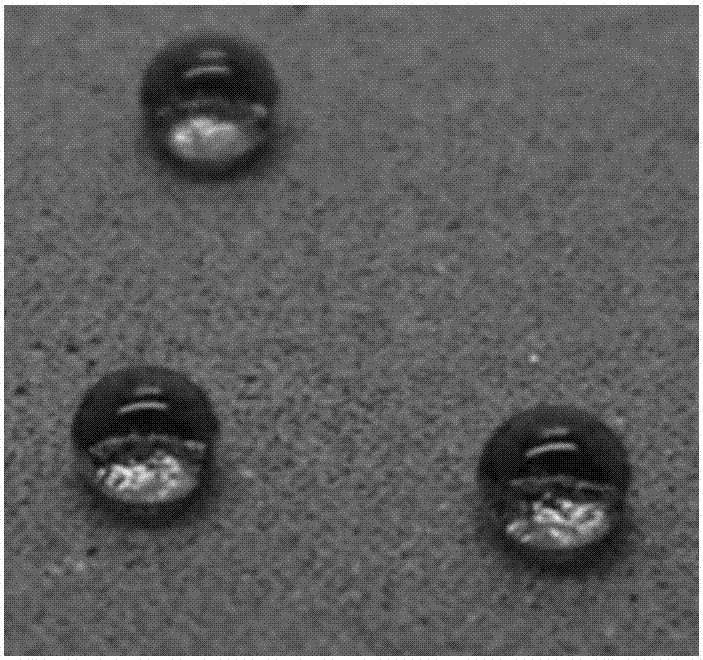

[0027] (2) Pour the cement slurry after mixing into a plastic petri dish, paste the 80-mesh red copper mesh on the lower surface of the wooden board with a pressure of 10Pa with strong double-sided adhesive, and cover the lower surface of the wooden board covered with copper mesh on the mold superior. After being naturally air-dried, remove the board to obtain a superhydrophobic concrete block with a water contact angle of 158±0.8° and a rolling angle of 6.1±1.2° (such as figure 1 , figure 2 , image 3 shown).

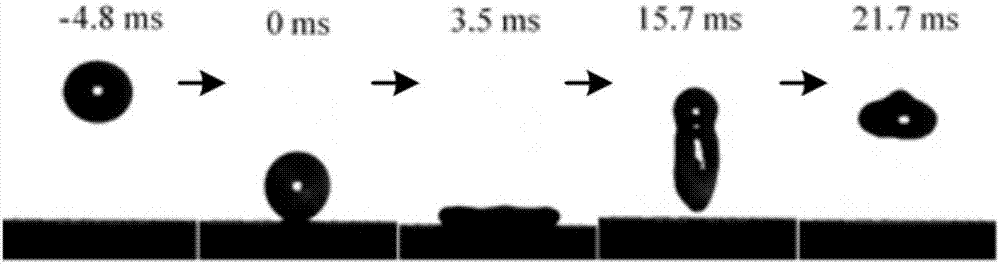

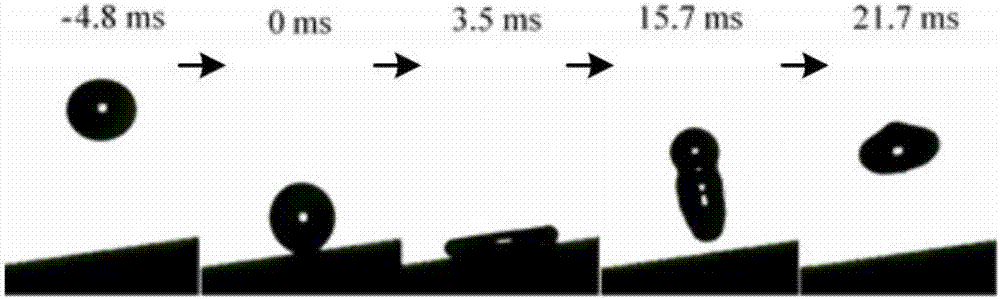

[0028] (3) In order to verify the anti-freezing rain and anti-icing performance of the super-hydrophobic concrete block, the super-hydrophobic concrete block and the ordinary concrete block were placed in the environmental chamber with an inclination of 30°,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com