Carbon fiber base gradient composite anode material for manganese electrodeposition and preparing method of material

A technology of composite anode and anode material, applied in electrodes, electrolytic coatings, metal material coating processes, etc., can solve the problems of increasing impurities in cathode products, poor corrosion resistance of anodes, and reducing product quality, etc., to improve electrical conductivity and Corrosion resistance, improved oxidation resistance and thermal shock resistance, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

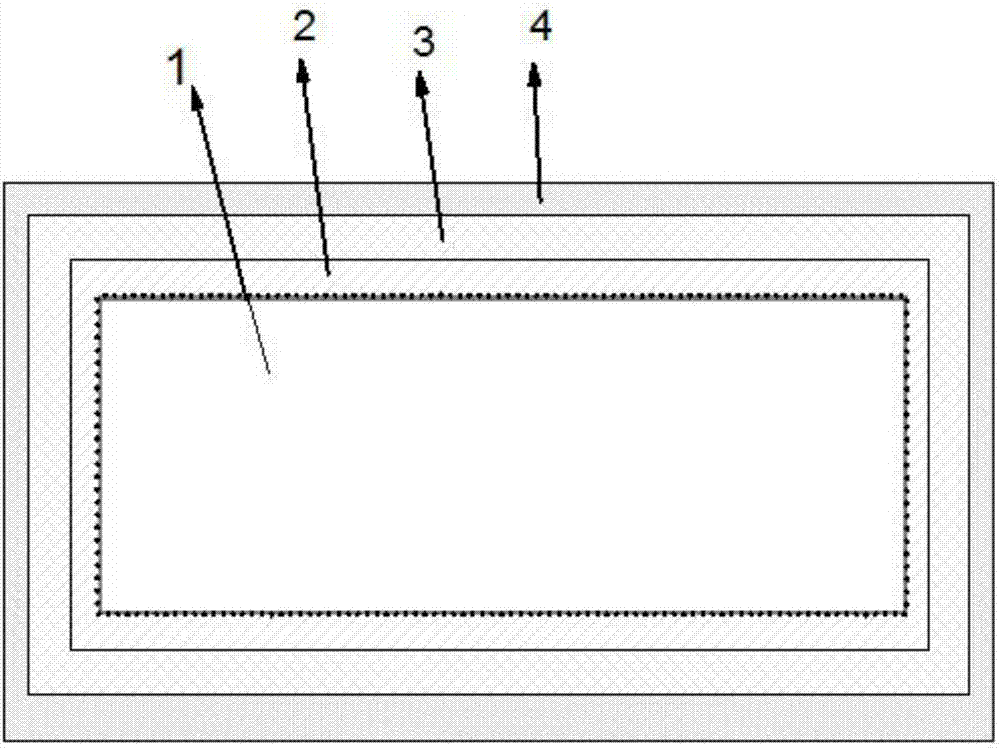

[0028] Such as figure 1 As shown, the carbon fiber-based gradient composite anode material for manganese electrowinning of the present invention includes a carbon fiber matrix 1, and the α-PbO compounded on the surface of the carbon fiber matrix that introduces nano-graphene particles 2 Composite coating 2, composite in α-PbO 2 The introduction of SiO on the surface of composite coating 2 2 Granular β-PbO 2 Composite coating 3, covered in β-PbO 2 The introduction of RuO on the surface of composite coating 3 2 Granular β-MnO 2 Composite coating4.

[0029] α-PbO described in this example 2 The composition of graphene particles in composite coating 2 is 2wt%, β-PbO 2 SiO in Composite Coating 3 2 Particle composition is 3.5 wt%, β-MnO 2 RuO in Composite Coating 4 2 The particle composition was 15% by weight. The total thickness of composite anode material is 8mm, the thickness of carbon fiber matrix is 4.8mm, α-PbO 2 Composite coating thickness is 0.5mm, β-PbO 2 Com...

Embodiment 2

[0039] The structure of the carbon fiber-based gradient composite anode material for manganese electrowinning in this embodiment is the same as that in Embodiment 1. The α-PbO 2 The composition of graphene particles in composite coating 2 is 1.57wt%, β-PbO 2 SiO in Composite Coating 3 2 Particle composition is 5wt%, β-MnO 2 RuO in Composite Coating 4 2 The particle composition was 10 wt%. The total thickness of composite anode material is 13mm, the thickness of carbon fiber matrix is 11mm, α-PbO 2 Composite coating thickness is 0.3mm, β-PbO 2 Composite coating thickness is 0.5mm, β-MnO 2 Composite coating thickness is 0.2mm.

[0040] The preparation method of carbon fiber-based gradient composite anode material for manganese electrowinning is as follows:

[0041] (1) Firstly, the carbon fiber matrix 1 is degummed, and under the protection of nitrogen or argon, it is heated at 700-800°C to increase the active specific surface of the carbon fiber, and at the same time ...

Embodiment 3

[0049] The structure of the carbon fiber-based gradient composite anode material for manganese electrowinning in this embodiment is the same as that in Embodiment 1. The α-PbO 2 The composition of graphene particles in composite coating 2 is 4wt%, β-PbO 2 SiO in Composite Coating 3 2 Particle composition is 2.01wt%, β-MnO 2 RuO in Composite Coating 4 2 The particle composition was 25% by weight. The total thickness of composite anode material is 4mm, the thickness of carbon fiber matrix is 3mm, α-PbO 2 Composite coating thickness is 0.1mm, β-PbO 2 Composite coating thickness is 0.39mm, β-MnO 2 Composite coating thickness is 0.01mm.

[0050] The preparation method of carbon fiber-based gradient composite anode material for manganese electrowinning is as follows:

[0051] (1) Firstly, the carbon fiber matrix 1 is degummed, and under the protection of nitrogen or argon, it is heated at 600-700°C to increase the active specific surface of the carbon fiber, and at the sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com