Electric aluminium

A technology of anodizing aluminum and titanium dioxide, applied in the field of anodizing aluminum, can solve problems such as insufficient performance and insufficient tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

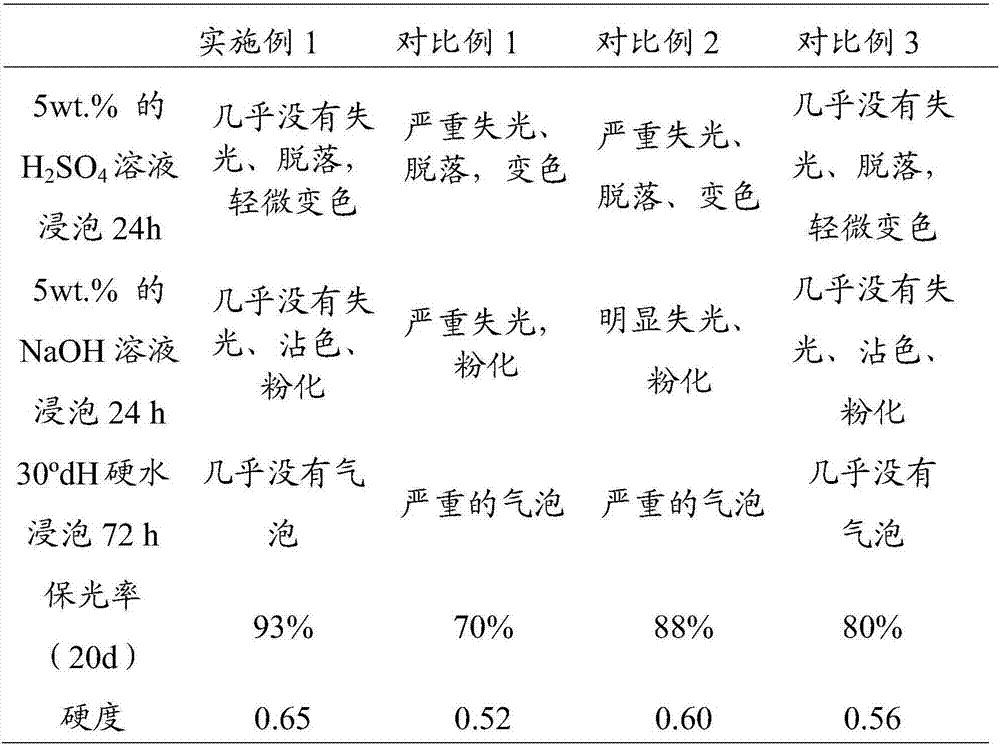

Examples

preparation example Construction

[0035] The present invention also provides a preparation method of electrochemical aluminum, comprising the following steps:

[0036] S100, providing the base film;

[0037] S200, coating the release layer on the base film, the coating speed is 80m / min, the coating temperature is 100°C, and the dry coating amount is 0.2~1.0g / m 2 ;

[0038] S300, coating the color layer on the release layer, the coating speed is 100m / min, the coating temperature is 120°C, and the dry coating amount is 0.6~1.2g / m 2 ;

[0039] S400, vacuum aluminum plating on the base film coated with release layer and color layer, the aluminum plating speed is 80m / min, and the dry coating amount is 0.2~0.5g / m 2 ;as well as

[0040]S500, coating the product obtained by vacuum aluminum plating with an adhesive layer, the coating speed is 100m / min, the coating temperature is 110°C, and the dry coating amount is 0.6-1.2g / m 2 .

Embodiment 1

[0042] Components:

[0043] Base film: select the gram weight as 18g / m 2 , PET (polyethylene terephthalate) with a thickness of 12u is the base film layer.

[0044] Water-based release layer: 2.5 parts of ethylene vinyl acetate copolymer modified polypropylene wax, 3 parts of modified oxidized polyethylene wax with silicon hydroxyl group, 0.1 part of silicone defoamer, 25 parts of ethanol, 25 parts of deionized water;

[0045] Water-based color layer: 25 parts of water-based acrylic emulsion, 8 parts of water-based magenta, 10 parts of modified cellulose, 5 parts of alumina-coated titanium dioxide (particle size 60nm), 0.2 parts of silicone defoamer, 35 parts of deionized water;

[0046] Water-based adhesive layer: 25 parts of water-based acrylic resin, 5 parts of water-based terpene resin, 5 parts of fumed silica (particle size 70nm), 30 parts of deionized water, and 0.3 parts of silicone defoamer.

[0047] preparation:

[0048] Add 25 parts of ethanol and 25 parts of deio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com