Steel for ship and preparation method of steel

A technology for steel and hull, applied in the field of steel for hull and its preparation, can solve the problems of insufficient impact toughness, low welding performance, poor corrosion resistance, etc., and achieve the goal of improving strength, good mechanical strength, and preventing grain boundary and dislocation migration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

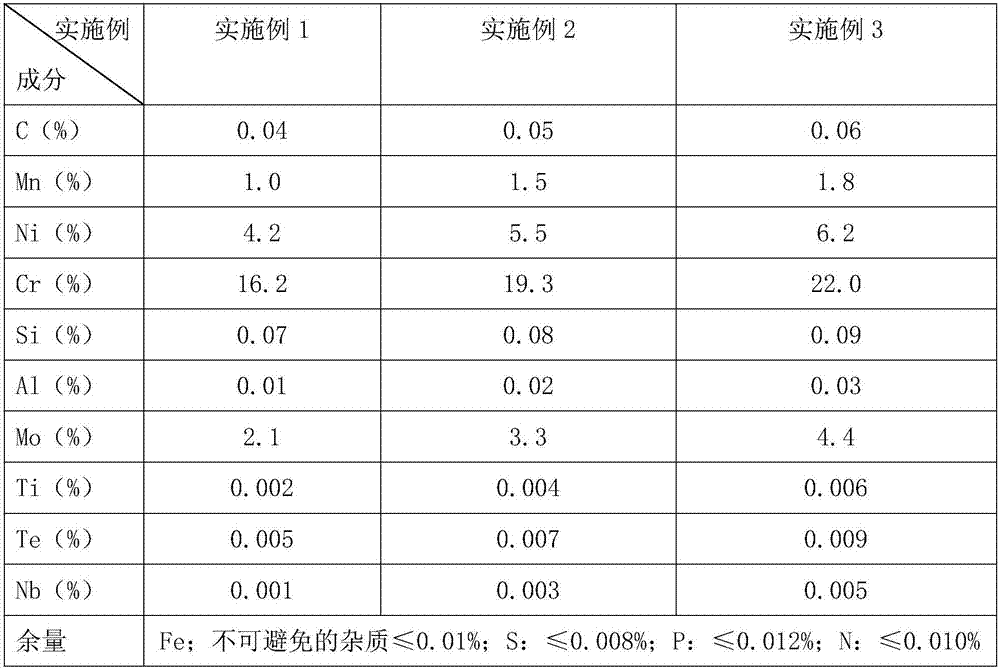

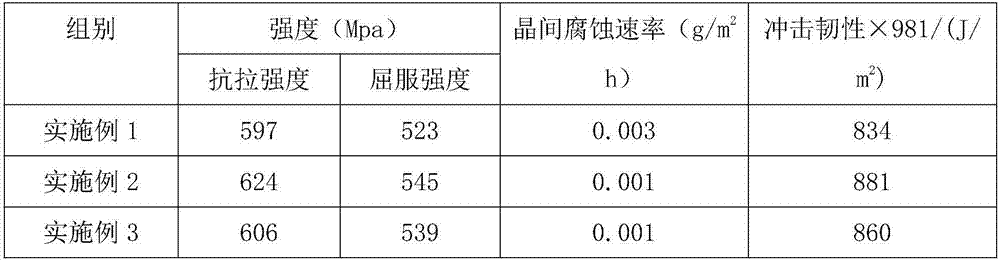

Embodiment 1

[0028] The above-mentioned preparation method of steel for a hull is carried out according to the following steps:

[0029] (1) Put industrial raw materials ferromanganese, ferrochrome, ferromolybdenum, ferronickel, limestone, dolomite and silicon carbide in an electric furnace for smelting, control the composition of the mother liquor in the electric furnace within the above percentage content, and control the temperature of the molten steel at 1520°C;

[0030] (2) Transfer the released mother liquor to the argon-oxygen refining furnace for oxygen blowing decarburization, nitrogen blowing and composition adjustment (regulated according to the above table 1);

[0031] (3) Cast molten steel into ingots at 1640°C;

[0032] (4) Forging the above-mentioned ingot at 1080° C. into a steel product, and then further hot-rolling it into a 1 mm steel plate;

[0033] (5) Finally, the rolled steel plate is subjected to solid solution and quenching treatment, and the temperature of soluti...

Embodiment 2

[0035] The above-mentioned preparation method of steel for a hull is carried out according to the following steps:

[0036] (1) Put industrial raw materials ferromanganese, ferrochrome, ferromolybdenum, ferronickel, limestone, dolomite and silicon carbide in an electric furnace for smelting, control the composition of the mother liquor in the electric furnace within the above percentage content, and control the temperature of the molten steel at 1600°C;

[0037] (2) Transfer the released mother liquor to the argon-oxygen refining furnace for oxygen blowing decarburization, nitrogen blowing and composition adjustment (regulated according to the above table 1);

[0038] (3) Cast molten steel into ingots at 1700°C;

[0039] (4) Forging the above-mentioned ingot at 1120° C. into steel, and then further hot-rolling it into a 3mm steel plate;

[0040] (5) Finally, the rolled steel plate is subjected to solid solution and quenching treatment, and the temperature of solution treatmen...

Embodiment 3

[0042] The above-mentioned preparation method of steel for a hull is carried out according to the following steps:

[0043] (1) Put the industrial raw materials ferromanganese, ferrochrome, ferromolybdenum, ferronickel, limestone, dolomite and silicon carbide in an electric furnace for smelting, control the composition of the mother liquor in the electric furnace within the above percentage content, and control the temperature of molten steel out of the furnace at 1680°C;

[0044] (2) Transfer the released mother liquor to the argon-oxygen refining furnace for oxygen blowing decarburization, nitrogen blowing and composition adjustment (regulated according to the above table 1);

[0045] (3) Cast molten steel into ingots at 1760°C;

[0046] (4) Forging the above-mentioned ingot at 1080-1160° C. into steel, and then further hot-rolling it into a 5 mm steel plate;

[0047] (5) Finally, the rolled steel plate is subjected to solid solution and quenching treatment, and the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com