High-temperature direct-injection dispersion ink and preparation method thereof

A technology of dispersing ink and high temperature, applied in ink, dyeing method, textile and papermaking, etc., can solve the problems of high requirements for preparation of additives, complex preparation process, high cost, etc., and achieves no secondary pollution, preparation steps Simple, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

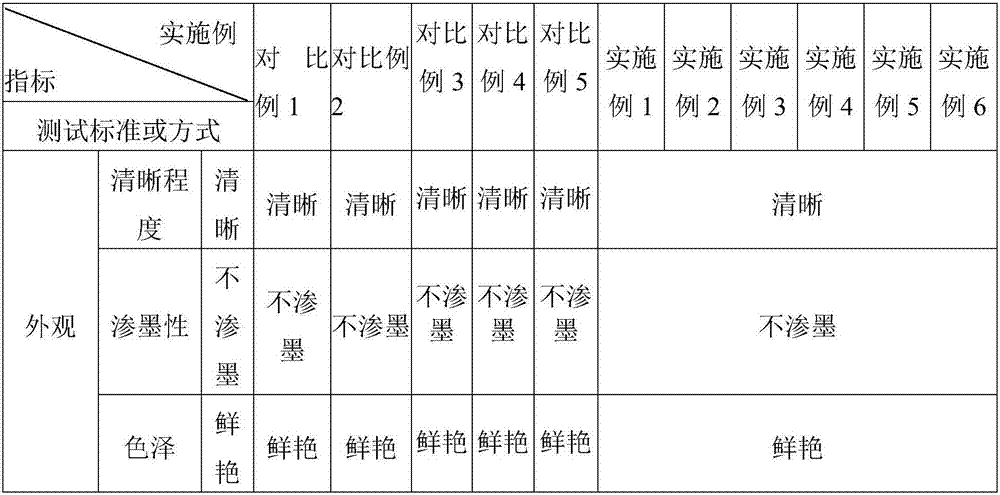

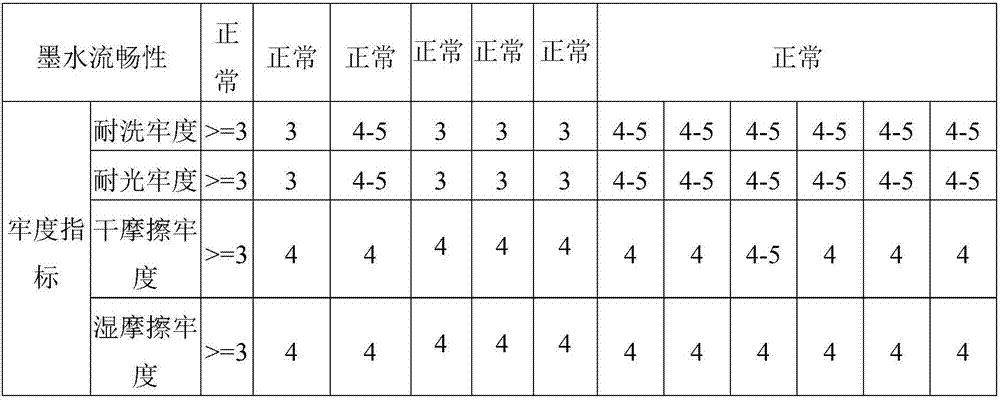

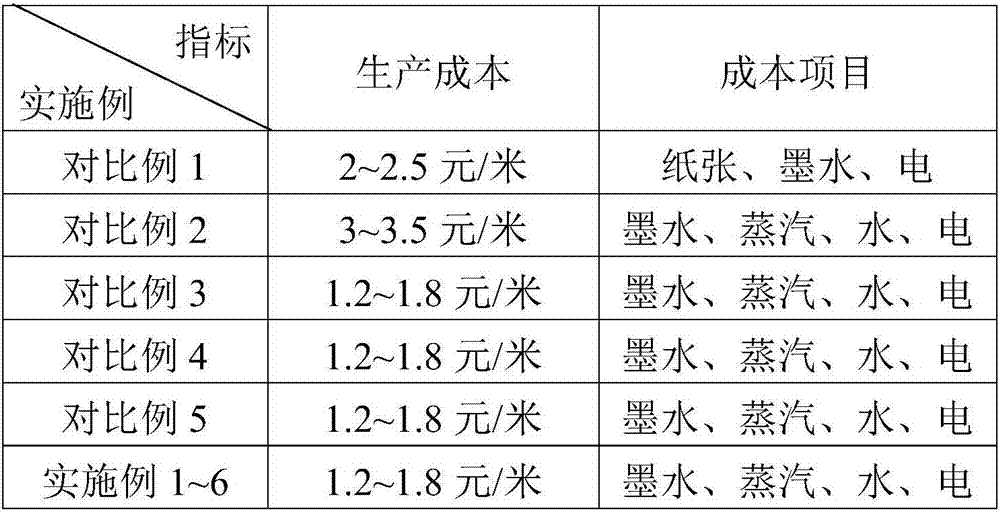

Examples

Embodiment 1

[0050] Embodiment 1 Preparation and Application of High Temperature Direct Injection Disperse Red Ink

[0051] 1. Preparation of high-temperature direct-injection disperse red ink

[0052] Put 40 parts of high temperature disperse red dye 54 into the reaction kettle, add 40 parts of ethylene glycol, 50 parts of water, 2 parts of surfactant Surfynol 465, 0.3 parts of isothiazolinone, 0.5 parts of triethanolamine and 4 parts of ethylenediamine , after stirring at a speed of 60 rpm for 2 hours, filter with a filter membrane (PP membrane) with a pore size of 0.22 μm, and the obtained filtrate is the high-temperature direct-injection disperse red ink.

[0053] 2. Application of high temperature direct injection disperse red ink obtained in step 1

[0054] The specific usage method is:

[0055] (1) Printing: The above-mentioned high-temperature direct-injection disperse red ink is used for direct inkjet printing in an industrial digital textile printing machine (namely, the Starli...

Embodiment 2

[0058] Embodiment 2 Preparation and Application of High Temperature Direct Injection Dispersed Green Ink

[0059] 1. Preparation of High Temperature Direct Injection Dispersed Green Ink

[0060] Put 45 parts of high-temperature disperse green dye 19 into the reaction kettle, add 45 parts of glycerol, 55 parts of water, 2 parts of surfactant Surfynol 465, 0.3 part of isothiazolinone, 0.5 part of dimethylethanolamine and 4 parts of ethyl alcohol After diamine was stirred at a speed of 60 rpm for 2 hours, it was filtered through a filter membrane (PP membrane) with a pore size of 0.22 μm, and the obtained filtrate was high-temperature direct-injection dispersion green ink.

[0061] 2. Application of the high-temperature direct-injection disperse green ink obtained in step 1

[0062] The specific usage method is:

[0063] (1) Printing: The above-mentioned high-temperature direct-injection disperse green ink is used for direct inkjet printing in industrial digital textile printin...

Embodiment 3

[0066] Embodiment 3 Preparation and Application of High Temperature Direct Injection Dispersed Blue Ink

[0067] 1. Preparation of high-temperature direct-injection disperse blue ink

[0068] Put 50 parts of high temperature disperse blue dye 87 into the reaction kettle, add 50 parts of ethylene glycol, 60 parts of water, 3 parts of surfactant Surfynol 465, 0.3 parts of isothiazolinone, 0.5 parts of triethanolamine and 5 parts of ethylenediamine , after stirring at a speed of 60 rpm for 2 hours, filter with a filter membrane (PP membrane) with a pore size of 0.22 μm, and the obtained filtrate is high-temperature direct-injection disperse blue ink.

[0069] 2. Application of the high-temperature direct-injection disperse blue ink obtained in step 1

[0070] The specific usage method is:

[0071] (1) Printing: The above-mentioned high-temperature direct-injection disperse blue ink is used for direct ink-jet printing in industrial digital textile printing machines (i.e. Xinggua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com