Pretreatment method of tea leaves in black tea processing

A technology for green tea and black tea, which is applied in the field of green tea pretreatment for black tea processing, can solve the problems of affecting the appearance and taste of tea leaves, long rolling time, long fermentation time, etc., achieves good viewing value and taste, and shortens rolling time. and fermentation time, the effect of shortening the cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

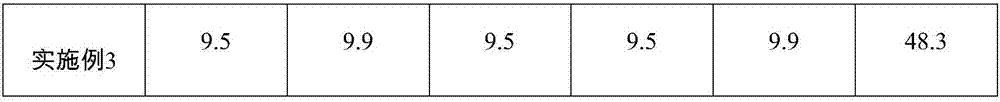

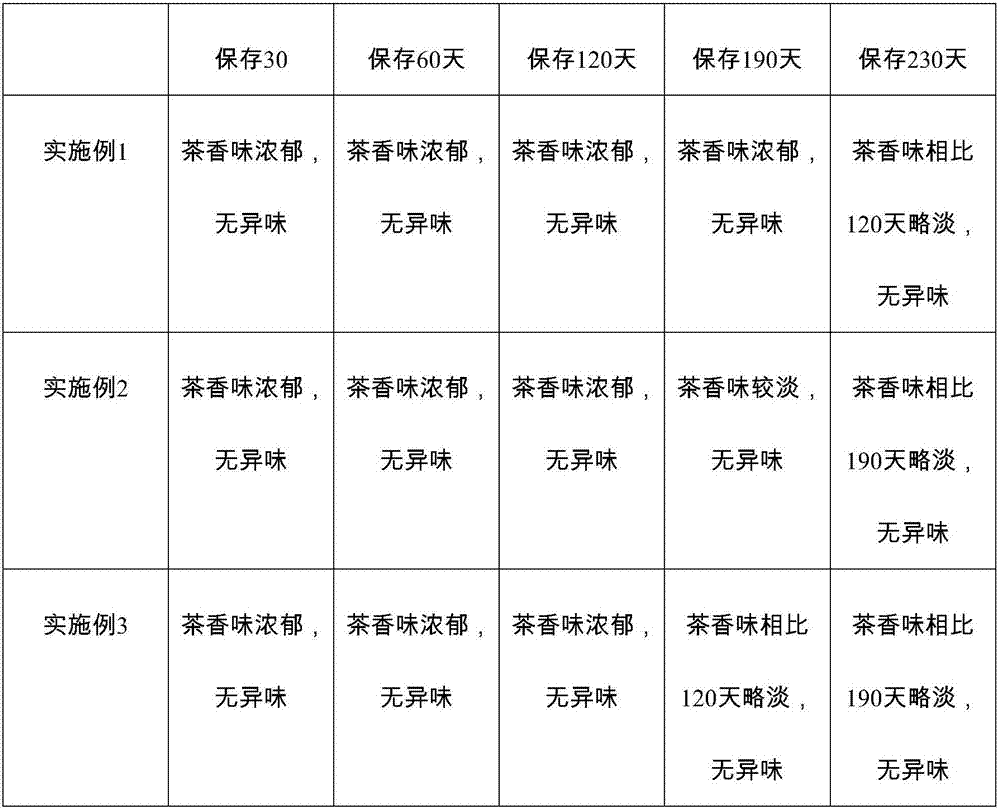

Embodiment 1

[0044] Pick non-polluting tea greens as raw materials, and put them in baskets or baskets with good air permeability to keep them fluffy and ventilated; spread them under natural wind until the leaves become soft and the water content drops to 50%; the tea greens are withered at low temperature for 4 hours , the temperature is -3°C; then the green tea is put into a kneading machine for low-temperature rolling, the temperature is 7°C, the time is 10 minutes, and the pressurization method is light-heavy-light; the green tea after kneading is put into automatic fermentation In the machine, the fermentation temperature is kept at 28°C, the humidity is 70%, and the fermentation lasts for 1 hour; the fermented black tea is dried at a temperature of 90°C for 25 minutes; The temperature of Pei Tixiang is 100°C, the baking time is 2 hours, and the moisture content of black tea is 8%. It is sealed in a special black tea storage bag and stored in a dark place.

Embodiment 2

[0046] Pick non-polluting tea greens as raw materials, and put them in baskets or baskets with good air permeability to keep them fluffy and ventilated; spread them under natural wind until the leaves become soft and the water content drops to 55%; the tea greens are withered at low temperature for 6 hours , the temperature is -10°C; then the green tea is put into a kneading machine for low-temperature rolling, the temperature is 5°C, the time is 15 minutes, and the pressurization method is light-heavy-light; the green tea after kneading is put into automatic fermentation In the machine, the fermentation temperature is kept at 25°C, the humidity is 80%, and the fermentation duration is 1.2h; the fermented black tea is dried at a temperature of 100°C; the dried black tea is roasted to enhance the aroma. The temperature is 105°C, the baking time is 1.5 hours, and the moisture content of black tea is 7%. It is sealed with a special black tea storage bag and stored in shading.

Embodiment 3

[0048]Pick non-polluting tea greens as raw materials, and put them in baskets or baskets with good air permeability to keep them fluffy and ventilated; spread them under natural wind until the leaves become soft and the water content drops to 70%; the tea greens are withered at low temperature for 7 hours , the temperature is -20°C; then the green tea is put into the automatic fermentation machine, the fermentation temperature is kept at 30°C, the humidity is 95%, and the fermentation duration is 2h; the fermented black tea is dried at a temperature of 110°C for 25 Minutes; the dried black tea is roasted to enhance the aroma, the temperature of the roasting is 100°C, the roasting time is 2 hours, and the moisture content of the black tea is 6%; it is sealed with a special black tea storage bag and stored in shading.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com