Laying hen feed for producing calcium-rich and zinc-rich nutritional eggs and preparation method of feed

A layer feed and high-zinc technology, applied in animal feed, animal feed, additional food elements, etc., can solve the problems of shortened laying cycle, lower laying rate of laying hens, and failure to achieve good results, so as to be easily absorbed and utilized , Improve the effect of the chicken house environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

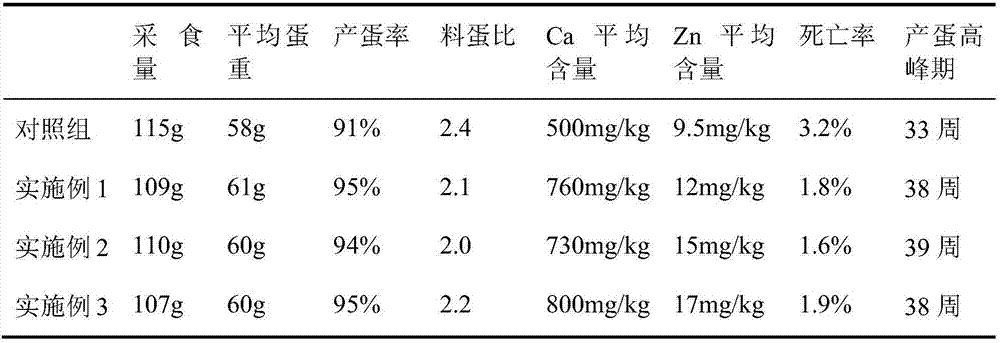

Examples

Embodiment 1

[0038] This embodiment prepares a kind of laying hen feed.

[0039] The feed preparation process is as follows: crush the layer feed base material, add water to prepare, mix well → microwave treatment for disinfection and sterilization → inoculate 0.2% Bacillus cereus and 160mg / kg Bacillus megaterium at 80°C, ventilate and ferment for 24 hours → complete the fermentation , cool down to 37°C, add 110g / kg calcium lactate, 3g / kg zinc gluconate, 0.1% glycyl glutamine, 0.5% high nucleic acid yeast hydrolyzate, mix thoroughly → pack into bags.

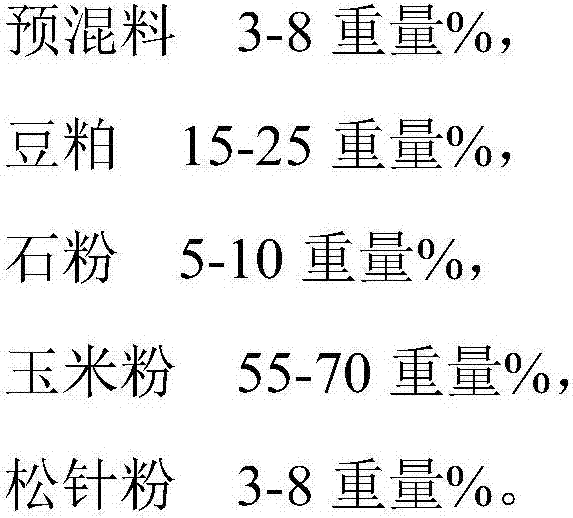

[0040] The laying hen feed base material comprises: 5% of premixed material; 19% of soybean meal; 8% of stone powder; 63% of corn flour; and 5% of pine needle powder.

Embodiment 2

[0042] This embodiment prepares a kind of laying hen feed.

[0043]The feed preparation process is as follows: crush the feed base material for laying hens, add water to prepare, mix well → microwave treatment for disinfection and sterilization → inoculate 0.15% Bacillus cereus and 200mg / kg Bacillus megaterium at a high temperature of 75°C, ventilate and ferment for 24 hours → complete fermentation , cool down to 25°C, add 115g / kg calcium lactate, 3.5g / kg zinc gluconate, 0.08% glycyl glutamine, 0.4% high nucleic acid yeast hydrolyzate, mix well → pack into bags.

[0044] The laying hen feed base material comprises: 5% of premixed material; 19% of soybean meal; 8% of stone powder; 63% of corn flour; and 5% of pine needle powder.

Embodiment 3

[0046] This embodiment prepares a kind of laying hen feed.

[0047] The feed preparation process is as follows: crush the layer feed base material, add water to prepare, mix well → microwave treatment for disinfection and sterilization → inoculate 0.4% Bacillus cereus and 120mg / kg Bacillus megaterium at 85°C, ventilate and ferment for 24 hours → complete fermentation , cool down to 37°C, add 120g / kg calcium lactate, 4g / kg zinc gluconate, 0.2% glycyl glutamine, 0.3% high nucleic acid yeast hydrolyzate, mix thoroughly → pack into bags.

[0048] The laying hen feed base material comprises: 5% of premixed material; 19% of soybean meal; 8% of stone powder; 63% of corn flour; and 5% of pine needle powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com