Low-fat crisp seasoning powder and preparation method thereof

A brittle, flour product technology, applied in the direction of food ingredients as gelling agent, function of food ingredients, food forming, etc., can solve problems such as potential harm, high salt body, high oil, etc., to increase the amount of dietary fiber , Crispy taste, the effect of reducing the amount of lipids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

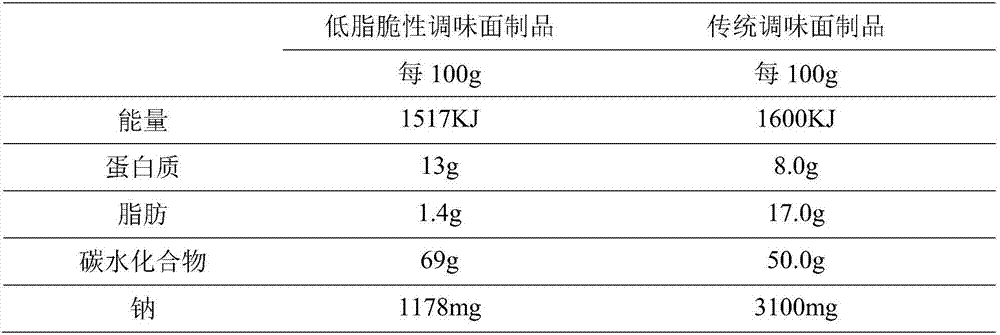

Examples

preparation example Construction

[0022] Another aspect of the present invention provides a kind of preparation method of described low-fat brittle seasoning noodle product, and this preparation method comprises the steps:

[0023] (1) Flour mixing: fully mix wheat flour, soybean fiber powder, inulin, konjac powder, salt and water;

[0024] (2) Twin-screw extrusion expansion: the mixed material obtained in step (1) is put into a twin-screw extrusion extruder for extrusion expansion to obtain a primary billet;

[0025] (3) Slitting and cooling: Slitting and cooling the primary billets in turn;

[0026] (4) Secondary puffing with low pressure difference: performing low-pressure secondary puffing on the cooled primary billet, and vacuum heating and dehydration to obtain puffed billets with a honeycomb structure;

[0027] (5) Grinding and seasoning: grind white sugar, monosodium glutamate, dried chili powder and Chinese prickly ash and mix uniformly to obtain seasoning, then fully vibrate and mix the seasoning wi...

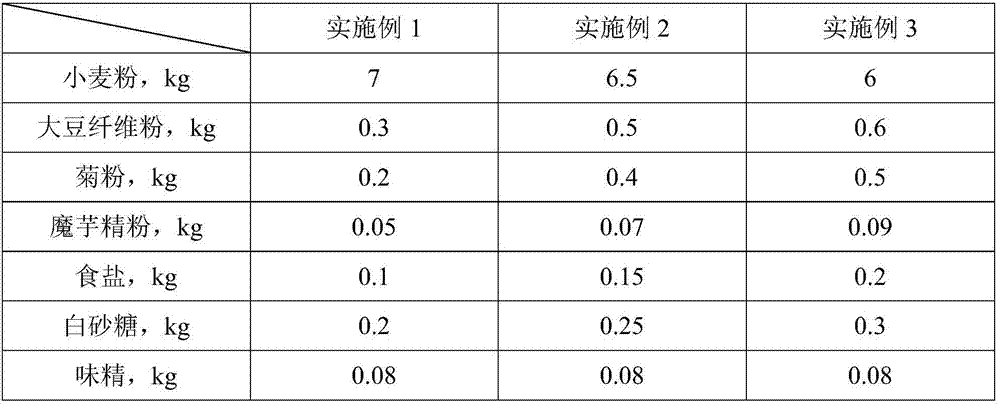

Embodiment 1

[0039] The preparation method of the low-fat brittle seasoning noodle product of the present embodiment is:

[0040] (1) Flour mixing: get a certain amount of wheat flour, soybean fiber powder, inulin, konjac fine powder, salt and water and fully mix;

[0041] (2) Twin-screw extrusion puffing: put the mixed material obtained in step (1) into the sleeve of the twin-screw extrusion puffing machine, open the water valve of the twin-screw extrusion puffing machine, and push through the screw and unload the mold The heating effect makes the dough in a high pressure state up to 6MPa and a high temperature of about 190°C. The dough is extruded through the die mouth, the pressure suddenly drops, the water evaporates rapidly, and the dough expands accordingly. Due to the loss of water, a large amount of heat is taken away, so that the temperature of the dough suddenly drops to about 60-80 ° C, so that the dough is solidified and shaped, and obtained primary billet;

[0042] (3) Slitt...

Embodiment 2

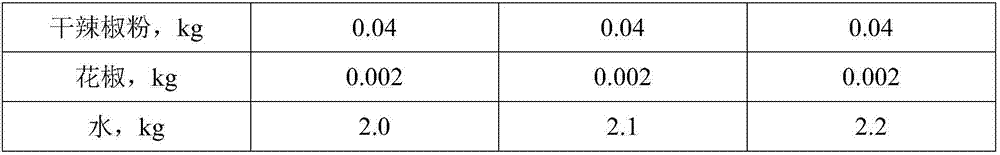

[0048] The preparation method of this example is the same as that of Example 1. The amount of raw materials used in this example is shown in Table 1, and the properties of the prepared product are shown in Table 3 and Table 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com