Spicy sauce and preparation method thereof

A technology of chili sauce and chili powder, which is applied in the direction of food ingredients as antioxidants, food ingredients containing oil, food ingredients containing gas, etc., can solve problems such as poor product preservation effect, unbalanced nutrition of hot sauce, and excessive formula of hot sauce. , to achieve the effect of bright color, better seasoning effect and sufficient fresh and spicy taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

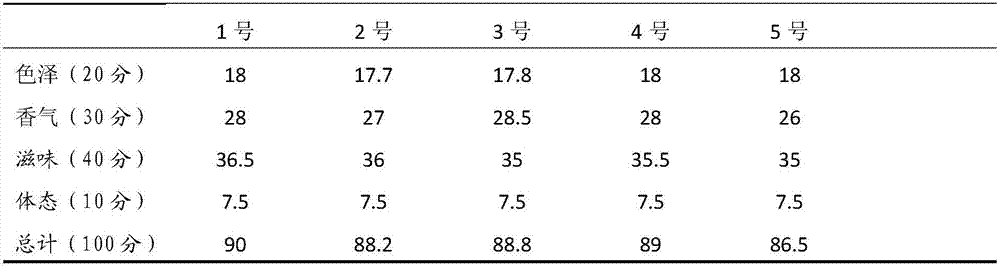

Embodiment 1

[0079] A kind of fragrant hot sauce, it adopts the hydrogen-filled sealing package, and it comprises following components by weight: 125 parts of edible vegetable oils, 75 parts of bean paste, 23 parts of chili powder, 15 parts of sesame seeds, 15 parts of perilla leaf fragments, 6 parts of Douchi, 7.5 parts of fresh ginger, 9 parts of garlic, 3 parts of green pepper powder, 2 parts of pepper, 18 parts of kelp residue, 21 parts of edible salt, 7.5 parts of honey, 6 parts of steamed fish sauce, 2 parts of rose water , 2 parts of jasmine dew and 4 parts of spice extract;

[0080] The edible vegetable oil is made of sesame oil, the chili powder is made by drying and crushing Guizhou peppercorns, the green pepper powder is made by crushing fresh Sichuan South Road peppercorns, and the honey is made of nectar;

[0081] The perilla leaf pieces are chopped to 1cm 2 Below, the particle diameter of described fresh ginger powder, garlic powder and kelp residue is controlled below 5mm, ...

Embodiment 2

[0101] A kind of spicy sauce, which adopts hydrogen-filled sealed packaging, and comprises the following components in parts by weight: 100 parts of edible vegetable oil, 60 parts of bean paste, 15 parts of chili powder, 10 parts of sesame seeds, 10 parts of perilla leaf fragments, 4 parts 1 part fermented soya bean, 5 parts fresh minced ginger, 6 parts minced garlic, 2 parts minced green pepper, 1 part pepper, 12 parts kelp residue, 16 parts edible salt, 5 parts honey, 4 parts steamed fish soy sauce, 1 part rose water , 1 part jasmine dew and 2 parts spice extract;

[0102] The edible vegetable oil is made of peanut oil, the chili powder is made by drying and crushing Guizhou pepper, the green pepper powder is made by crushing fresh Sichuan South Road pepper, and the honey is honey;

[0103] The perilla leaf pieces are chopped to 1cm 2 Below, the particle diameter of described fresh ginger powder, garlic powder and kelp residue is controlled below 5mm, and the particle diame...

Embodiment 3

[0123] A kind of fragrant hot sauce, it adopts the hydrogen-filled sealed package, and it comprises the following components in parts by weight: 150 parts of edible vegetable oil, 90 parts of bean paste, 30 parts of chili powder, 20 parts of sesame seeds, 20 parts of perilla leaf fragments, 8 parts of Douchi, 10 parts of fresh ginger, 12 parts of garlic, 4 parts of green pepper powder, 3 parts of pepper, 24 parts of kelp residue, 26 parts of edible salt, 10 parts of honey, 8 parts of steamed fish soy sauce, 3 parts of rose water , 3 parts of jasmine dew and 6 parts of spice extract;

[0124] The edible vegetable oil is made of sunflower oil, the chili powder is made by drying and crushing Guizhou peppercorns, the green pepper powder is made by crushing fresh Sichuan South Road peppercorns, and the honey is made of nectar;

[0125] The perilla leaf pieces are chopped to 1cm 2 Below, the particle diameter of described fresh ginger powder, garlic powder and kelp residue is contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vitality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com