Preparation method of multiple-mineral-matter vitamin preparation

A vitamin preparation and mineral technology, which is applied in the field of nutritional health food, can solve the problems of easy appearance of black spots, reduced content, and impact on product quality, etc., and achieves promotion of human metabolism, enhanced stability, and good coating effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] A preparation method of multi-mineral vitamin preparation, comprising the following steps:

[0020] 1) Vitamin D pretreatment: mix microcrystalline cellulose and 3% HPMC solution to make 10-mesh pellets, dilute the vitamin D oil solution with 95% alcohol 100:1 and spray on the pellets until the pellets fully absorb the vitamin D to saturated state, dry for use;

[0021] 2) Preparation of vitamin D-embedded granules: use purified water as solvent, mix coating agent A with water evenly to make a coating solution with a solid content of 15%, coat the pellets that have absorbed vitamin D, and dry until use;

[0022] 3) Pretreatment of divalent manganese ions: the divalent manganese is manganese sulfate, after mixing microcrystalline cellulose and manganese sulfate in a mass ratio of 2:1, mixture A is obtained, and further mixture A and binder 3% HPMC The solutions were mixed to make 10-mesh pellets, which were dried for later use;

[0023] 4) Preparation of divalent mang...

Embodiment 1

[0032] A multi-mineral vitamin preparation and a preparation method thereof, the specific preparation steps are as follows:

[0033] 1) Vitamin D pretreatment: Mix microcrystalline cellulose and 3% HPMC solution at a mass ratio of 3.5:1 to make 10-mesh pellets, dilute the vitamin D oil solution with 95% alcohol 100:1 and spray on the pellets After the pellets fully absorb vitamin D to a saturated state, dry it for use;

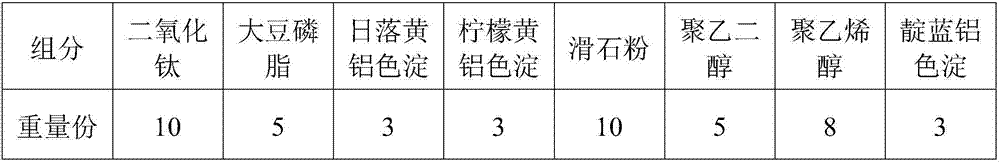

[0034] 2) Preparation of vitamin D embedding granules: use purified water as a solvent, mix coating agent A and water evenly to make a coating solution with a solid content of 15%, at an air inlet temperature of 60°C, and a tablet bed temperature of 38-42 Under the conditions of ℃, atomization pressure 2.0bar, coating pan speed 5rpm, and coating solution flow rate 80-100g / min, the vitamin D-absorbed pellets were coated and dried for use. The composition of coating agent A is shown in Table 1 Shown:

[0035] The composition of table 1 coating agent A

[0036...

Embodiment 2

[0044] A multi-mineral vitamin preparation and a preparation method thereof, the specific preparation steps are as follows:

[0045] 1) Vitamin D pretreatment: Mix microcrystalline cellulose and 3% HPMC solution at a mass ratio of 3.8:1 to make 10-mesh pellets, dilute the vitamin D oil solution with 95% alcohol 100:1 and spray on the pellets After the pellets fully absorb vitamin D to a saturated state, dry it for use;

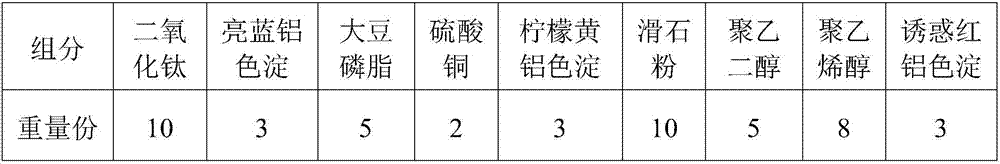

[0046] 2) Preparation of vitamin D embedding granules: use purified water as a solvent, mix coating agent A and water evenly to make a coating solution with a solid content of 15%, at an air inlet temperature of 60°C, and a tablet bed temperature of 38-42 Under the conditions of ℃, atomization pressure 2.0bar, coating pan speed 5rpm, and coating solution flow rate 80-100g / min, the vitamin D-absorbed pellets were coated and dried for use. The composition of coating agent A is shown in Table 1 Shown:

[0047] The composition of table 1 coating agent A

[0048...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com