De-sensitizing toothpaste and preparation method thereof

A technology for desensitizing toothpaste and peach gum, applied in dentistry, pharmaceutical formulations, allergic diseases, etc., can solve the problems of decreased desensitization effect, general desensitization effect, poor persistence of desensitization effect, etc., to improve the removal of bad breath. performance, good adhesion, improved durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

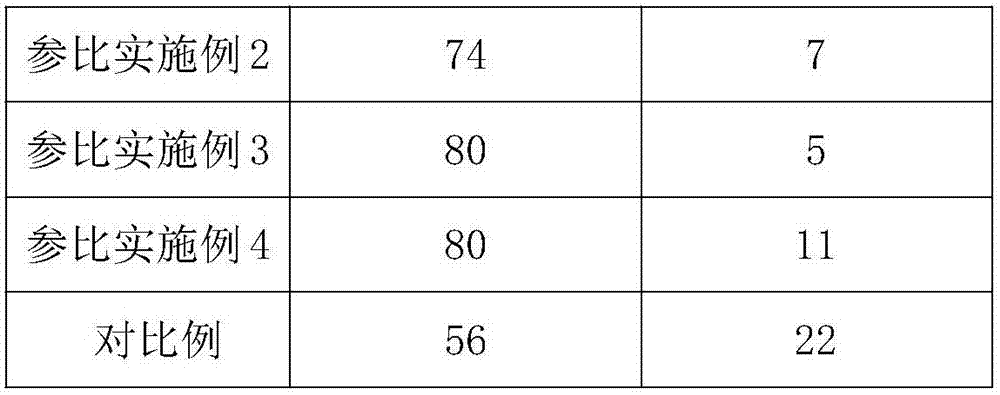

Examples

Embodiment 1

[0024] Desensitizing toothpaste, made of the following raw materials in parts by weight: 27 parts of glycerin, 2.5 parts of sodium lauryl sulfate, 32 parts of hydrated silicon dioxide, and a bonding agent made by mixing equal masses of sodium alginate and hydrolyzed peach gum 3 parts of stevioside, 2 parts of stevioside, 2.1 parts of eugenol, 5.5 parts of strontium chloride, 2.7 parts of co-desensitizer mixed with equal mass of tannin and zinc phenolsulfonate, 1.2 parts of sodium malate, deionized 30 parts of water.

[0025] The preparation method of this desensitization toothpaste comprises the following steps:

[0026] (1) Wash the persimmon skin with distilled water for 2 minutes, dry it at 70°C for 4 hours, and then crush it to 40 mesh to obtain persimmon skin powder. Add the persimmon skin powder to ethanol at a solid-liquid ratio of 1:14.5, and extract 2 Cool to room temperature after 1 hour, vacuum filter to obtain the filtrate, vacuum dry the filtrate at 70°C to obtai...

Embodiment 2

[0030] Desensitizing toothpaste, made of the following raw materials in parts by weight: 25 parts of glycerin, 3.5 parts of sodium lauryl sulfate, 44 parts of hydrated silicon dioxide, and a bonding agent made by mixing equal masses of sodium alginate and hydrolyzed peach gum 5 parts of stevioside, 1.6 parts of stevia, 2 parts of eugenol, 5 parts of strontium chloride, 3 parts of co-desensitizer mixed with equal mass of tannin and zinc phenolsulfonate, 2 parts of sodium malate, deionized 10 parts of water.

[0031] Its preparation method is identical with embodiment 1.

Embodiment 3

[0033] Desensitizing toothpaste, made of the following raw materials in parts by weight: 30 parts of glycerin, 4 parts of sodium lauryl sulfate, 40 parts of hydrated silicon dioxide, and a bonding agent made by mixing equal masses of sodium alginate and hydrolyzed peach gum 4.5 parts of stevioside, 1 part of stevia, 2.5 parts of eugenol, 6.5 parts of strontium chloride, 2 parts of co-desensitizer mixed with equal mass of tannin and zinc phenolsulfonate, 1 part of sodium malate, deionized 15 parts of water.

[0034] Its preparation method is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com