Medicine-carrying system of vitamin E-modified silicon-base hydrogel contact lens and preparation method of medicine-carrying system

A contact lens and silicon hydrogel technology, which is applied in the direction of medical formula, glasses/goggles, medical preparations with non-active ingredients, etc., can solve the problem of ofloxa in vitamin E modified silicon-based hydrogel contact lenses. Star loading research or reports and other issues, to achieve the effect of alleviating dry eye syndrome, good biocompatibility, and prolonging the sustained release time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

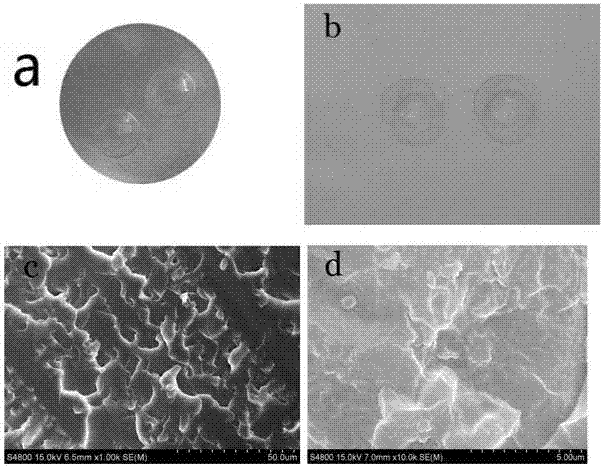

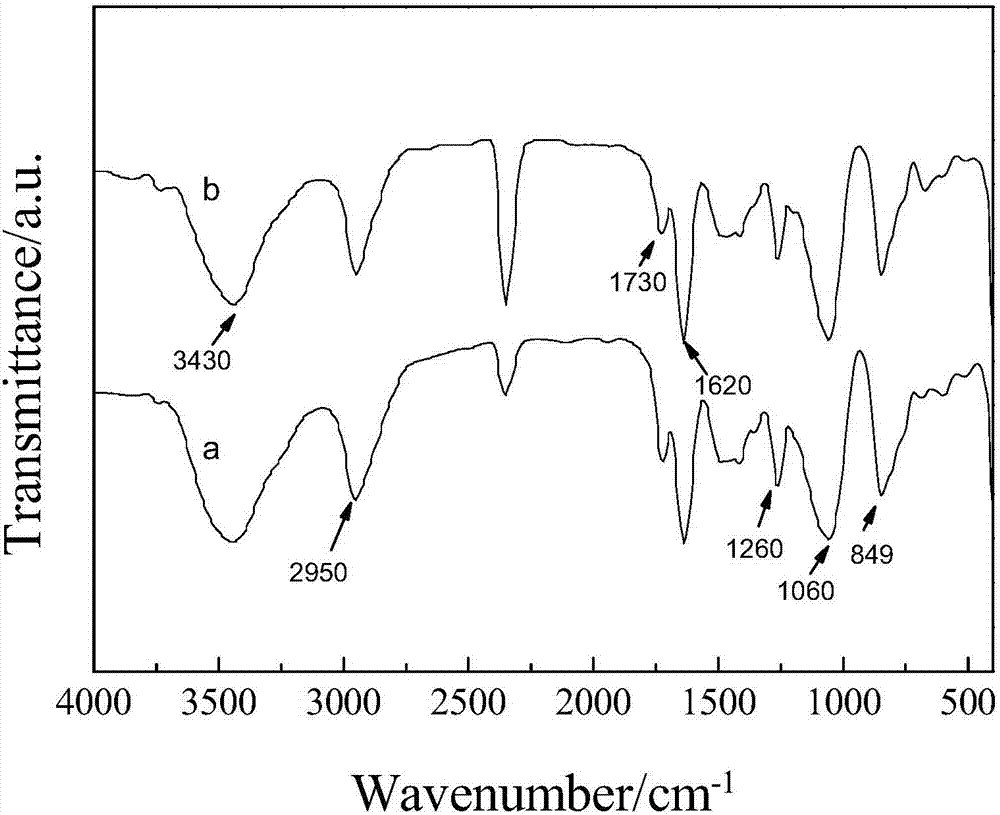

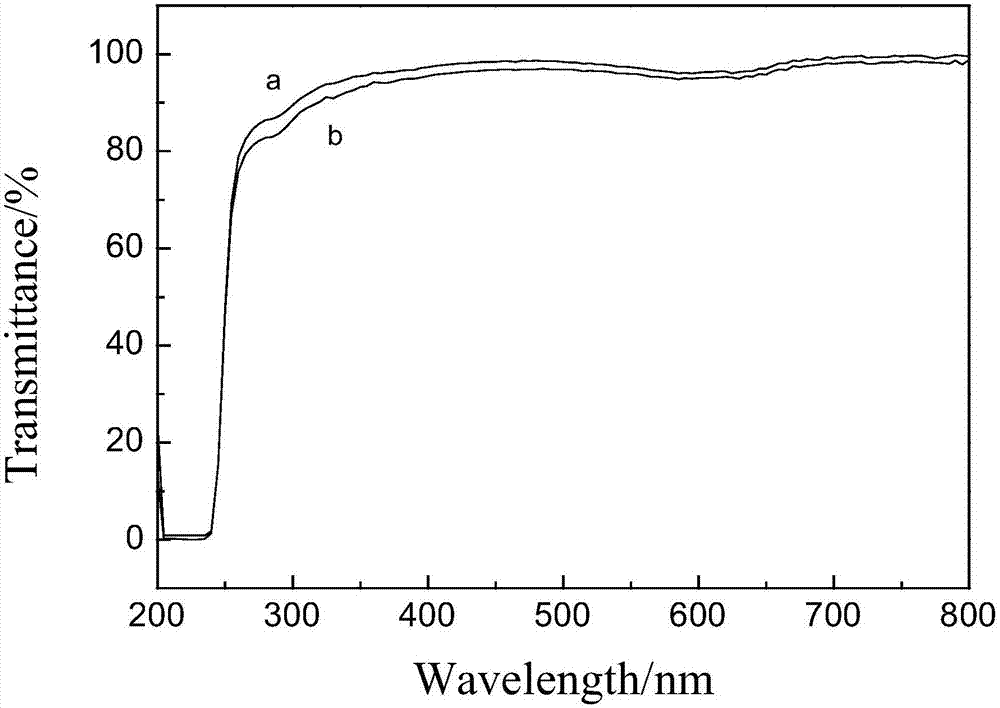

[0063] Step 1: Synthesizing a silicone prepolymer with a methacrylate end group, and curing it by a one-time compression molding method to obtain a silicon-based hydrogel.

[0064] Add GMA and KF8010 with a substance ratio of 1:1 into a 100ml flask and stir to mix evenly. 2 A drying tube was inserted on the flask to isolate moisture, and the prepolymer GKF8010 was obtained by stirring and reacting at 70°C for 5 hours. GKF8010, TRIS, Darocur1173 and 40% DMA were weighed and mixed in a 10ml beaker at a mass ratio of 28:28:6:38, and nitrogen gas was continuously injected into the beaker, and electric stirring was performed at room temperature for 9 hours. Drop the reacted mixture into the mold, press it tightly, irradiate with ultraviolet light for 5 minutes, soak the mold in distilled water overnight, and demould.

[0065] Step 2: Modification of silicon-based hydrogel contact lenses with vitamin E.

[0066] Take a piece of the prepared silicon hydrogel contact lens, soak it i...

Embodiment 2

[0070] Step 1: Synthesizing a silicone prepolymer with a methacrylate end group, and curing it by a one-time compression molding method to obtain a silicon-based hydrogel.

[0071] Add GMA and KF8010 with a substance ratio of 2:1 into a 100ml flask, stir and mix evenly, and fill with CaCl 2 A drying tube was inserted on the flask to isolate moisture, and the prepolymer GKF8010 was obtained by stirring and reacting at 80°C for 6 hours. Weigh GKF8010, TRIS, Darocur1173, and 40% DMA in a mass ratio of 28:29:5:38 and mix them uniformly in a 10ml beaker, continuously inject nitrogen gas into the beaker, and stir electrically at room temperature for 10 hours. Drop the reacted mixture into the mold, press it tightly, irradiate with ultraviolet light for 10 minutes, soak the mold in distilled water overnight, and demould.

[0072] Step 2: Modification of silicon-based hydrogel contact lenses with vitamin E.

[0073] Take a piece of the prepared silicon hydrogel contact lens, soak it...

Embodiment 3

[0077] Step 1: Synthesizing a silicone prepolymer with a methacrylate end group, and curing it by a one-time compression molding method to obtain a silicon-based hydrogel.

[0078] Add GMA and KF8010 with a substance ratio of 3:1 into a 100ml flask, stir and mix evenly, and fill with CaCl 2 A drying tube was inserted on the flask to isolate moisture, and the prepolymer GKF8010 was obtained by stirring and reacting at 90°C for 7 hours. GKF8010, TRIS, Darocur1173 and 40% DMA were weighed and mixed in a 10ml beaker according to the mass ratio of 29:29:4:38, and nitrogen gas was continuously injected into the beaker, and electric stirring was performed at room temperature for 11 hours. Drop the reacted mixture into the mold, press it tightly, irradiate with ultraviolet light for 15 minutes, soak the mold in distilled water overnight, and demould.

[0079] Step 2: Modification of silicon-based hydrogel contact lenses with vitamin E.

[0080] Take a piece of the prepared silicon h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com