PTFE composite filter bag having high-temperature catalytic decomposition function and preparation method thereof

A high-temperature catalysis and PTFE technology, applied in separation methods, chemical instruments and methods, dispersed particle filtration, etc., can solve the problems of increasing operating costs of waste incineration plants, difficult to decompose toxic and harmful gases, and discharge of toxic and harmful gases to achieve catalytic effects Improve, improve the surface finish, improve the effect of filtering accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

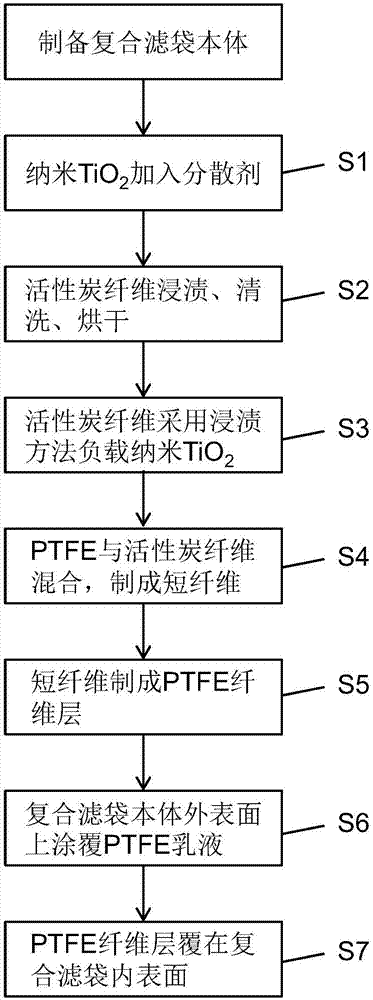

[0031] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

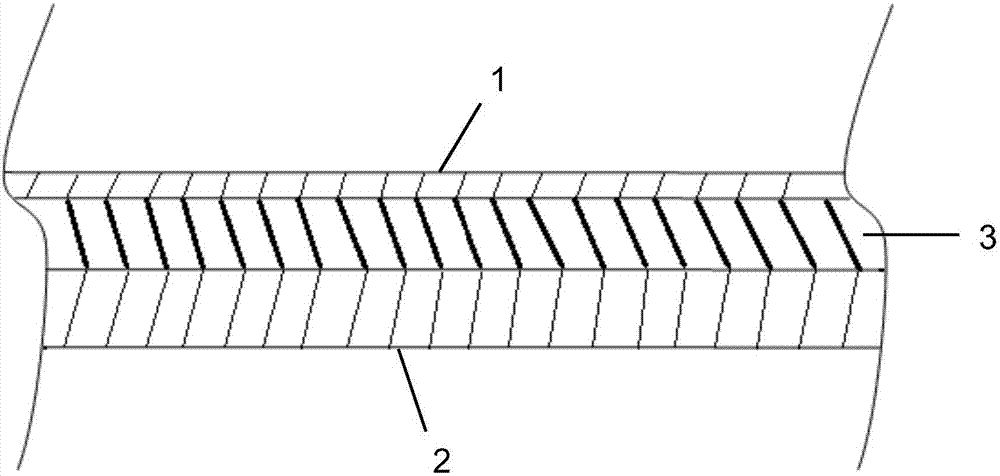

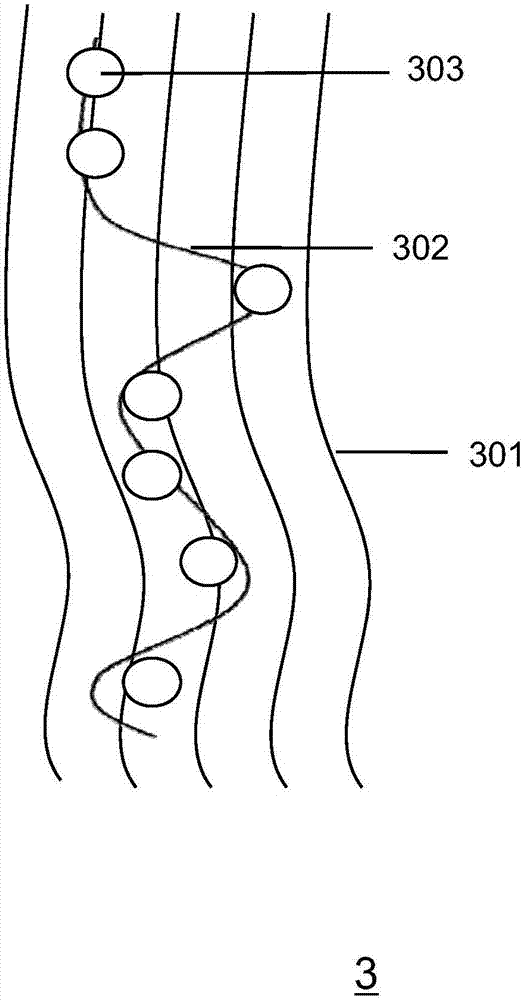

[0032] Please combine Figure 1 to Figure 2 As shown, a PTFE composite filter bag with high-temperature catalytic decomposition function provided by the present invention includes a composite filter bag body 1, and the composite filter bag body 1 is needle-punched felt or non-woven fabric, and the above is a prior art part. I won't repeat it here. Different from the prior art, the dust-facing surface (inner surface) of the composite filter bag body 1 is covered with a smooth layer 2, and the smooth layer 2 adopts PTFE emulsion, which improves the surface smoothness of the dust-facing surface of the composite filter bag. , which is conducive to the pulse cleaning in the actual use process, which improves the service life of the composite filter bag. There is also an adsorption layer 3 between the dust-facing surface of the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com