Preparation method of photocatalyst based on monodisperse elemental bismuth and carbon nitride

A photocatalyst and carbon nitride technology, which is applied in the direction of physical/chemical process catalysts, separation methods, chemical instruments and methods, etc., can solve the problem that the structure and shape of elemental bismuth particles are difficult to control, affect the reaction ability of composite photocatalysts, and composite materials Problems such as agglomeration are prone to occur, achieving uniform appearance, reducing preparation costs, and avoiding poor appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Use the method of the present invention to prepare the following materials, and carry out relevant characterization tests to the materials:

[0043] (1) Prepare carbon nitride with urea as the precursor. Dissolve 10g of urea in 20mL of deionized water, stir and dissolve, bake in an oven at 60°C for 8-12 hours to recrystallize, take it out and place it in a muffle furnace at 550°C Heating and calcining in medium temperature for 2 hours to obtain carbon nitride material;

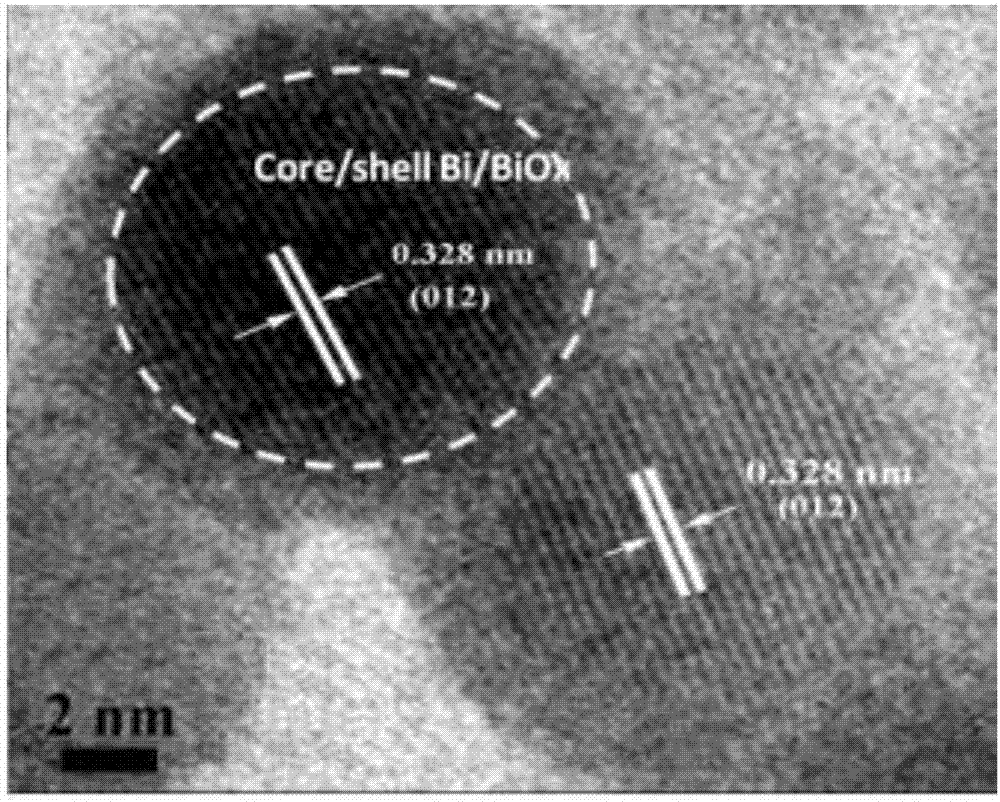

[0044] (2) Dissolve 1.0 mM bismuth dodecanoate, a precursor of bismuth, in 12 mL of tetralin, and heat and stir at 110° C. for 30 minutes after blowing nitrogen gas to remove oxygen and moisture in the system. After adding 0.24mL of dodecanethiol to the solution as a stabilizer, slowly add 1.5mL of reducing agent trioctylphosphine, pay attention to the color change in the system, the solution turns yellow after adding dodecanethiol, and trioctylphosphine After the base phosphine is added, the solution ...

Embodiment 2-5

[0055] The research is to control the size of bismuth particles in the bismuth / carbon nitride composite photocatalyst by using the method of the invention.

[0056] Prepare elemental bismuth particles according to step (2) in Example 1, and prepare elemental bismuth / carbon nitride composite materials of different sizes by controlling the reaction precursor and aging reaction temperature and time. The different formulations of Examples 3-6 The ratios and aging temperatures are shown in the table below:

[0057]

Example 2

Example 3

Example 4

Example 5

Dosage of trioctylphosphine (mL)

1.0

2.0

1.5

1.5

Aging reaction temperature (°C)

60

60

70

75

Aging reaction time (min)

30

30

5

5

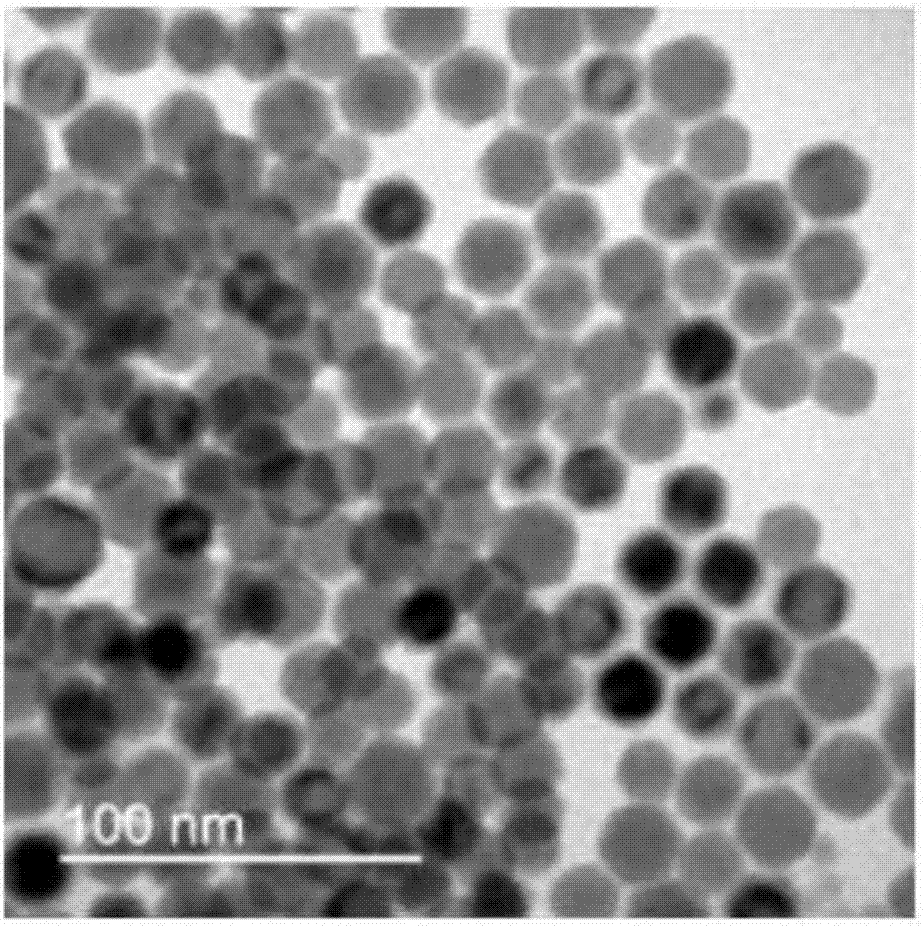

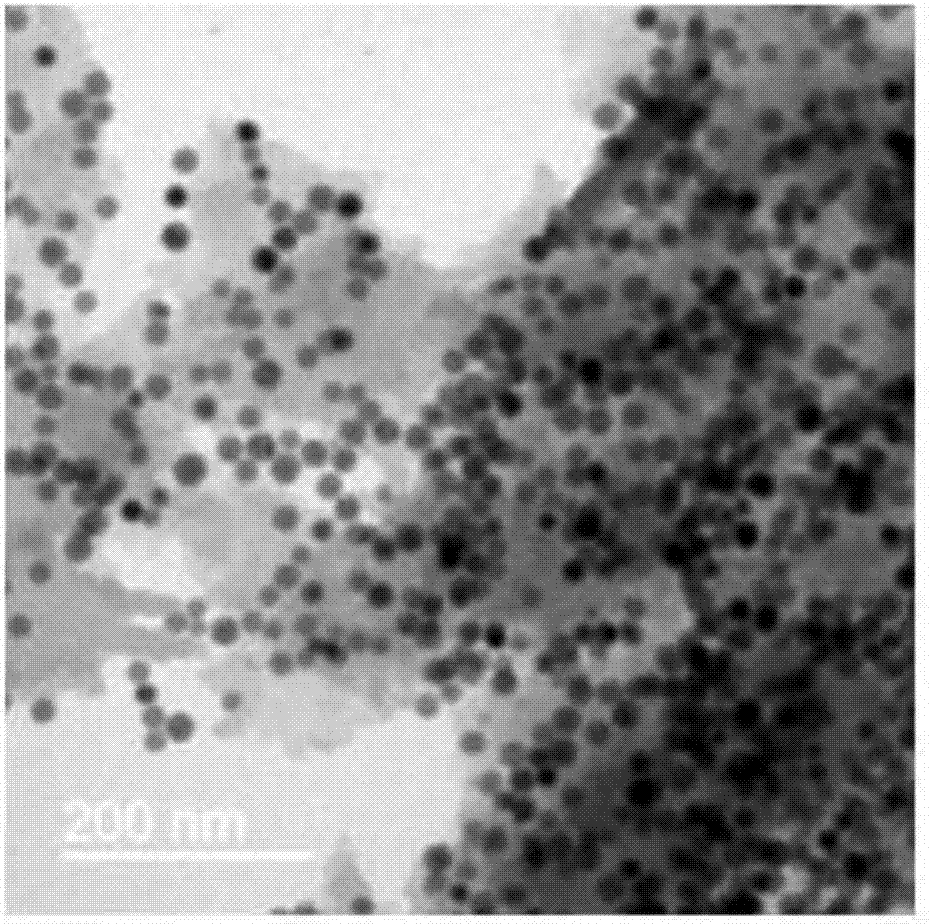

[0058] Figure 7 to Figure 10 It is a transmission electron microscope image of elemental bismuth particles with different particle sizes obtained according to Examples 2-5 of the present invention. It can be seen f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com