A kind of preparation method of zeolite hydrocarbon adsorption reforming catalyst

A reforming catalyst, hydrocarbon technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low desorption temperature, inability to meet the emission reduction requirements of motor vehicles, and no catalytic effect, etc. Achieve high desorption temperature, improve catalytic reforming effect, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

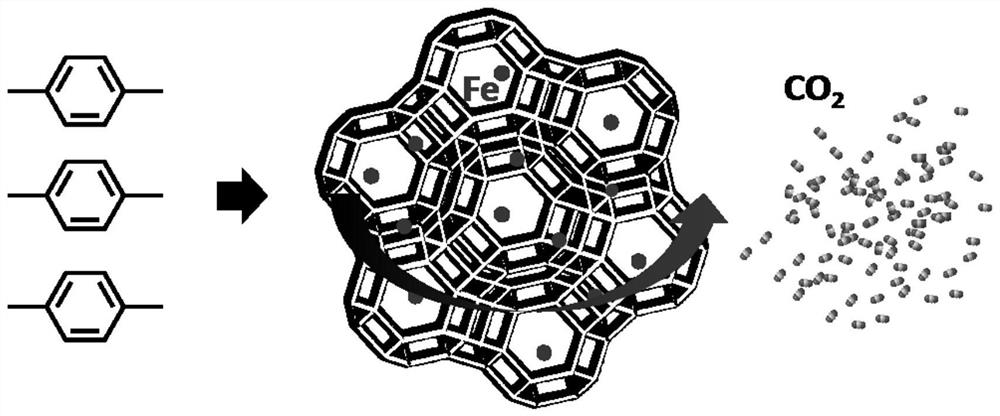

Method used

Image

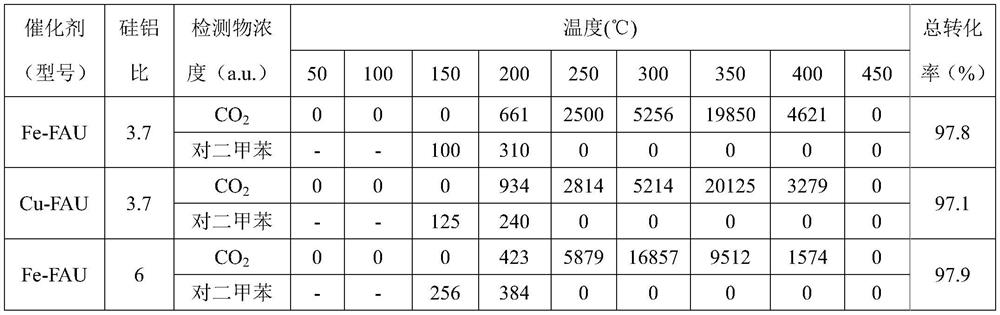

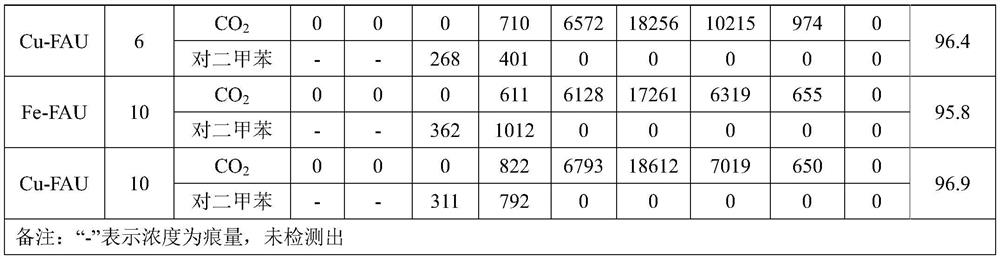

Examples

Embodiment 1

[0023] The preparation method of a kind of zeolite hydrocarbon adsorption reforming catalyst that the present invention proposes comprises the following steps:

[0024] The molecular sieve is mixed with the metal salt solution, stirred and reacted, filtered, washed and dried to obtain the zeolite hydrocarbon adsorption reforming catalyst.

Embodiment 2

[0026] The preparation method of a kind of zeolite hydrocarbon adsorption reforming catalyst that the present invention proposes comprises the following steps:

[0027] Mix the zeolite molecular sieve with the metal salt solution with a concentration of 0.6mol / L at a weight ratio of 1:15, stir for 26 hours, filter, wash, and dry at 105°C for 11 hours to obtain a zeolite with a molar ratio of silicon to aluminum of 3. whole catalyst.

Embodiment 3

[0029] The preparation method of a kind of zeolite hydrocarbon adsorption reforming catalyst that the present invention proposes comprises the following steps:

[0030] Mix the zeolite molecular sieve with a silicon-aluminum molar ratio of 4 and the metal salt solution with a concentration of 1.5mol / L at a weight ratio of 1:7, stir and react for 22 hours, filter, wash, and dry at 95°C for 13 hours to obtain zeolite carbon-hydrogen adsorption reforming catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com