Industrial molding binder for powder catalyst and application in preparing molding catalyst

A technology for forming binders and catalysts, which is applied in the directions of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc. It can solve problems such as inability to apply catalyst molding well, achieve high bonding performance, and catalyze The effect of high efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

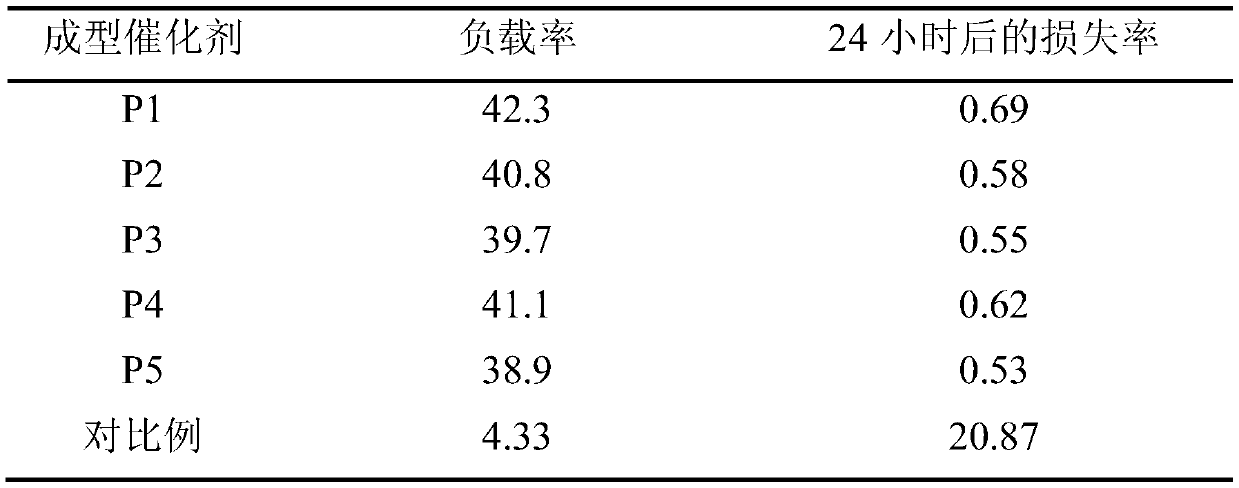

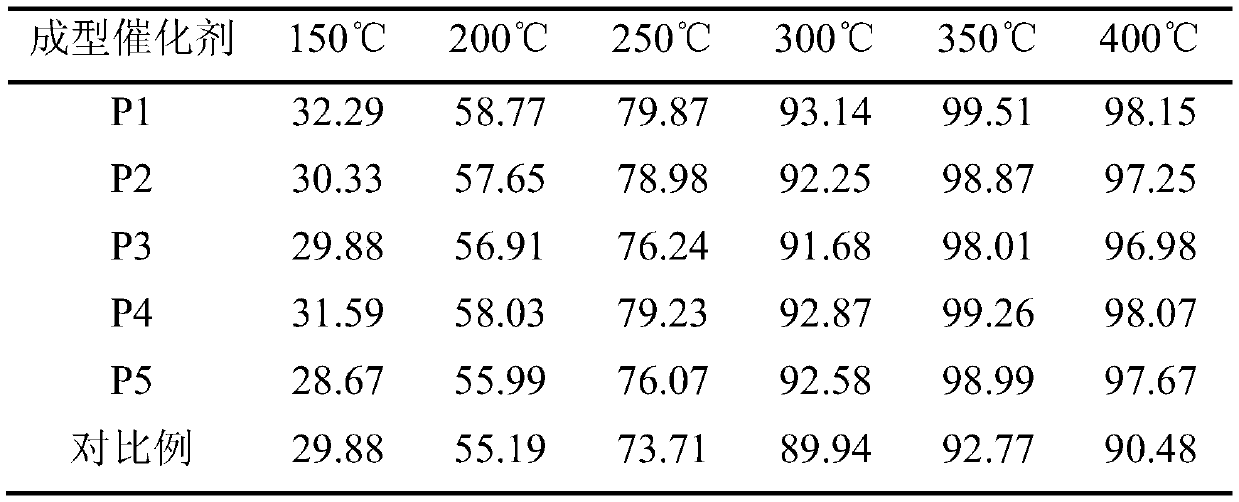

Examples

Embodiment 1

[0034] Cut the honeycomb ceramics with a pore diameter of 2 mm into small cubes with a length, width and height of 21 mm×21 mm×35 mm.

[0035] a) Preparation of powder catalyst industrial molding binder

[0036] a1) 0.50g methyltrimethoxysilane, 0.31g dimethyldimethoxysilane, 0.11g ethyl acetate, 0.02g ethylene glycol butyl ether, 0.07g phthalic acid bis(2-ethylhexyl ) ester, mixed with 0.04g methanol to obtain component A;

[0037] a2) Mix 6.03g methyltrimethoxysilane, 2.25g dimethyldimethoxysilane, 0.27g tetraisopropyl titanate, 0.18g methanol, and 0.27g propylene glycol methyl ether to obtain component B, silica sol pH = 8.0;

[0038] a3) Slowly raise the temperature of component A from normal temperature to 100°C, react at this temperature for 10 minutes, add component B, 10g of silica sol and 5g of ethanol, and stir thoroughly for 30 minutes to prepare a powder catalyst for industrial molding bonding agent.

[0039] b) Preparation of Shaped Catalyst P1

[0040] b1) A...

Embodiment 2

[0052] Cut the honeycomb ceramics with a pore diameter of 2 mm into small cubes with a length, width and height of 21 mm×21 mm×35 mm.

[0053] a) Preparation of powder catalyst industrial molding binder

[0054] a1) 0.70g methyltrimethoxysilane, 0.12g dimethyldimethoxysilane, 0.06g diethyl acetate, 0.01g ethylene glycol butyl ether, 0.07g dimethyl phthalate, 0.14g Methanol is mixed to obtain component A;

[0055] a2) Mix 6.81g of methyltrimethoxysilane, 2.54g of dimethyldimethoxysilane, 0.30g of n-propyl titanate, 0.20g of methanol, and 0.30g of dipropylene glycol dimethyl ether to obtain component B, silicon The pH of the sol=9.0;

[0056] a3) Slowly raise the temperature of component A from normal temperature to 100°C, react at this temperature for 10 minutes, add component B, 10g of silica sol and 5g of water, and stir thoroughly for 30 minutes to prepare a powder catalyst for industrial molding bonding agent.

[0057] b) Preparation of Shaped Catalyst P2

[0058] b1) ...

Embodiment 3

[0064] Cut the honeycomb ceramics with a pore diameter of 2 mm into small cubes with a length, width and height of 21 mm×21 mm×35 mm.

[0065] a) Preparation of powder catalyst industrial molding binder

[0066] a1) 0.50g methyltrimethoxysilane, 0.31g dimethyldimethoxysilane, 0.11g propyl acetate, 0.02g ethylene glycol butyl ether, 0.07g di-sec-octyl phthalate, 0.04g Methanol is mixed to obtain component A;

[0067] a2) Mix 10.50g methyltrimethoxysilane, 3.00g dimethyldimethoxysilane, 0.15g tetrabutyl titanate, 0.45g methanol, and 0.90g methyl tert-butyl ether to obtain component B, The pH of silica sol=10.0;

[0068] a3) Slowly raise the temperature of component A from normal temperature to 100°C, react at this temperature for 10 minutes, add component B, 10g of silica sol and 5g of n-hexane, stir thoroughly for 30 minutes, and prepare a powder catalyst industrial molding stick Binder.

[0069] b) Preparation of Shaped Catalyst P3

[0070] b1) Add 3 g of powdery denitrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com