Preparation method for anti-aging composite materials of sleepers

A composite material and anti-aging technology, applied in the field of track materials, can solve the problem of low anti-aging performance, and achieve the effects of enhancing anti-aging performance, improving anti-aging performance and reducing expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

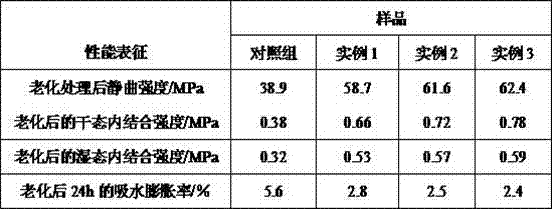

Examples

example 1

[0022] In terms of parts by weight, weigh 45 parts of bentonite, 35 parts of mica powder and 10 parts of titanium dioxide respectively and place them in a ball mill jar. : 10, mix the mixed ball mill powder and 5% aluminum sulfate solution by mass fraction, and disperse ultrasonically for 10 min at 200W to obtain a dispersion; mix bamboo and poplar wood with a mass ratio of 1:1 and airflow crush, pass through 50 mesh Sieve the mixed fiber, mix the mixed fiber with deionized water at a mass ratio of 1:10, stir and disperse to obtain a fiber mixed solution, add 5% hydrogen peroxide dropwise to the fiber mixed solution at a volume ratio of 1:20, stir After mixing for 20 minutes, the modified solution was obtained, and then according to the enzyme dosage of 20 U / g, xylanase was added to the modified solution, heated in a water bath at 50°C for 25 minutes, and then 5% sodium hydroxide solution was added dropwise to pH 8.0, after stirring and mixing for 2 hours, the enzymolysis mixt...

example 2

[0024] In terms of parts by weight, weigh 47 parts of bentonite, 37 parts of mica powder and 12 parts of titanium dioxide respectively and place them in a ball milling tank. : 10, mixing the mixed ball mill powder with mass fraction 5% aluminum sulfate solution, and ultrasonically dispersing at 250W for 12 minutes to obtain a dispersion; according to the mass ratio of 1:1, moso bamboo and poplar wood were mixed and jet-pulverized, and passed through 50 mesh Sieve the mixed fiber, mix the mixed fiber with deionized water at a mass ratio of 1:10, stir and disperse to obtain a fiber mixed solution, add 5% hydrogen peroxide dropwise to the fiber mixed solution at a volume ratio of 1:20, stir After mixing for 22 minutes, the modified solution was obtained, and then according to the enzyme dosage of 20 U / g, xylanase was added to the modified solution, heated in a water bath at 52°C for 27 minutes, and then 5% sodium hydroxide solution was added dropwise to pH 8.0, after stirring and...

example 3

[0026]In terms of parts by weight, weigh 50 parts of bentonite, 40 parts of mica powder and 15 parts of titanium dioxide respectively and place them in a ball mill jar. : 10, mixing the mixed ball mill powder with mass fraction 5% aluminum sulfate solution, and ultrasonically dispersing at 300W for 15min to obtain a dispersion; according to the mass ratio of 1:1, moso bamboo and poplar wood were mixed and jet-pulverized, and passed through 50 mesh Sieve the mixed fiber, mix the mixed fiber with deionized water at a mass ratio of 1:10, stir and disperse to obtain a fiber mixed solution, add 5% hydrogen peroxide dropwise to the fiber mixed solution at a volume ratio of 1:20, stir After mixing for 25 minutes, the modified solution was obtained, and then according to the enzyme dosage of 20 U / g, xylanase was added to the modified solution, heated in a water bath at 55°C for 30 minutes, and then 5% sodium hydroxide solution was added dropwise to pH 8.0, after stirring and mixing fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com