Production method of beta-phase silicon nitride, and beta-phase silicon nitride

A technology of phase silicon nitride and production methods, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of intermittent production pollution, poor product quality uniformity, occupational health damage, etc., and shorten the production cycle. , Controllable performance, the effect of prolonging the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment provides a method for producing β-phase silicon nitride, comprising the following steps:

[0026] Feed raw material silicon and nitrogen into at least two fluidized bed devices connected in series for reaction at a reaction temperature of 1281-1600° C. to obtain β-phase silicon nitride.

[0027] In this example, the raw material silicon and nitrogen gas are fed into at least two-stage series fluidized bed devices to react at 1281-1600°C, and the multi-stage series series fluidized bed devices prolong the residence time of raw material silicon and nitrogen gas in it. Time, thereby increasing the contact time of raw material silicon and nitrogen, controlling the reaction rate of silicon and nitrogen, which is conducive to prolonging the reaction time, improving reaction efficiency, shortening the production cycle, and further improving the yield and uniformity of the generated β-phase silicon nitride .

Embodiment 2

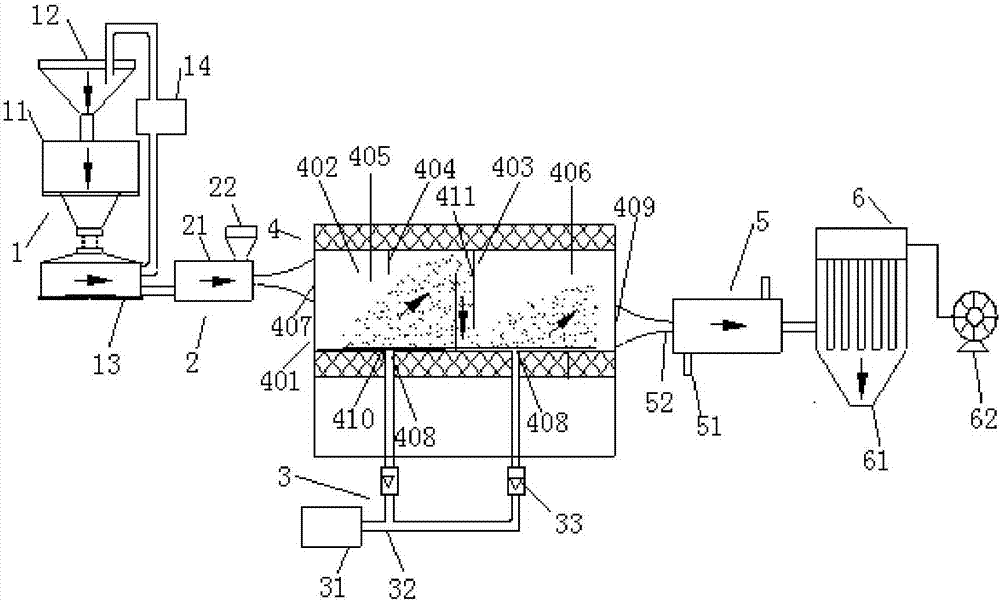

[0029] like figure 1 As shown, the present embodiment provides a production method of β-phase silicon nitride, comprising the following steps:

[0030] Pass silicon powder with a particle size of 1 μm, nitrogen, and auxiliary material silicon nitride with a particle size of 20 μm into the fluidized bed device 4 in series in two stages for reaction, wherein the mass ratio of the silicon powder to the auxiliary material is 1:10, the pressure in the fluidized bed device 4 is 50KPag, the reaction temperature is 1400°C, and the reaction time in each stage of the fluidized bed device 4 in series is 600 seconds to obtain β-phase silicon nitride. The auxiliary material can separate or disperse the silicon solid phase. The auxiliary material silicon nitride has the function of separating or dispersing the silicon solid phase, avoiding the formation of by-products, and further facilitating the improvement of the yield of β-phase silicon nitride.

[0031] In this embodiment, the raw ma...

Embodiment 3

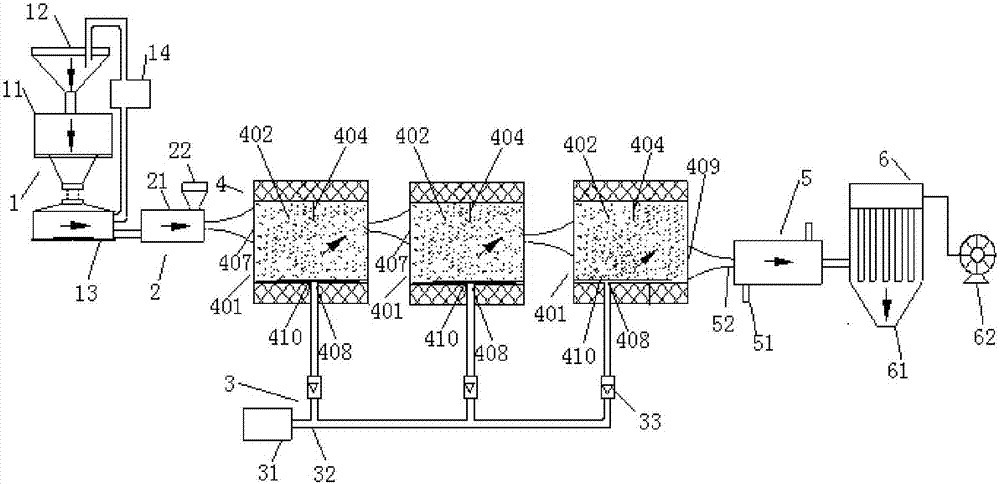

[0061] like figure 2 As shown, the present embodiment provides a production method of β-phase silicon nitride, comprising the following steps:

[0062] Pass silicon powder with a particle size of 60 μm, nitrogen, and auxiliary material silicon nitride into a three-stage series fluidized bed device 4 for reaction, wherein the mass ratio of the silicon powder to the auxiliary material is 10:1, and the flow The pressure in the fluidized bed device 4 is 0 KPag, the reaction temperature is 1600° C., and the reaction time in each stage of the fluidized bed device 4 in series is 300 seconds to obtain β-phase silicon nitride. The auxiliary material can separate or disperse the silicon solid phase. The auxiliary material silicon nitride has the function of separating or dispersing the silicon solid phase, avoiding the formation of by-products, and further facilitating the improvement of the yield of β-phase silicon nitride.

[0063] like figure 2 As shown, the difference between t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com