A cadmium-ammonia waste water zero-discharge process for a thin-film solar cell production line

A solar cell and production line technology, which is applied in the direction of energy wastewater treatment, water pollutants, multi-stage water treatment, etc., can solve the problems of incompatibility and other problems, achieve localization, reduce investment and operating costs, and solve zero discharge of cadmium and ammonia wastewater Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

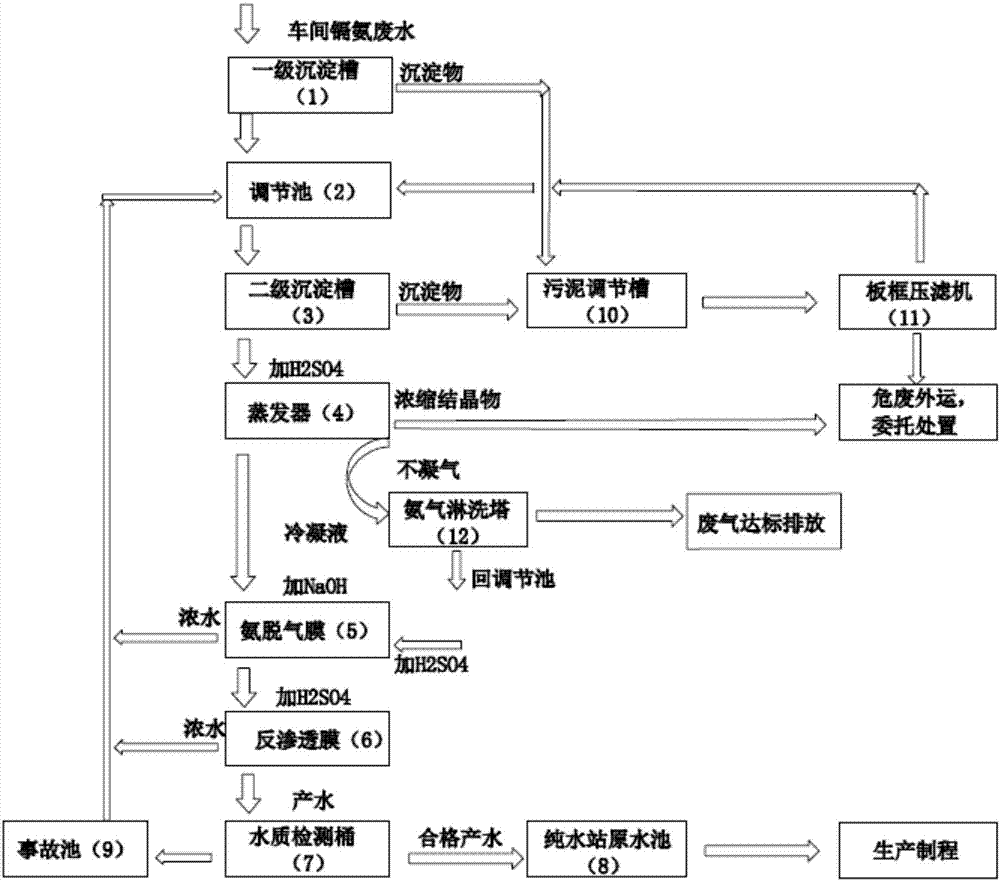

Method used

Image

Examples

example 1

[0034] Example 1: A thin-film solar technology Co., Ltd., copper indium gallium selenium solar cell module industrialization project (first phase project).

[0035] 1. Design water volume

[0036] The volume of cadmium and ammonia wastewater in the workshop is 87.8m3 / d, with an average of 3.66m3 / h.

[0037] 2. Design water quality

[0038] Total Cd57.62mg / L, ammonia 5161.69mg / L, S concentration 369.59mg / L, COD Cr 10000.00mg / L, pH9~11.

[0039] 3. Material output

[0040] (1) The produced water is reused in the pure water station of the production process, with a water volume of 87.8m 3 / d, water quality main control indicators: the concentration of cadmium and other metals is less than 0.0005mg / L, the concentration of ammonia nitrogen is 0.60mg / L, COD cr 2.90mg / L, pH6.5~7.5.

[0041] (2) Tail gas emission, the total amount of ammonia gas is 169.95g / d.

[0042] (3) Hazardous waste entrusted to qualified units for disposal: its solid components: compounds containing cadmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com