Low energy consumption method and device for rotational flow evaporation of liquid ammonia in power plants

A technology with low energy consumption and vaporized liquid, applied in the field of ammonia vaporization in coal-fired power plants, can solve the problems of low safety factor and high energy consumption of ammonia vaporization system, and achieve the effects of reducing the risk of explosion, improving ammonia vaporization rate, and simplifying ammonia vaporization system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] The present invention is further described below in conjunction with specific examples. However, it should be understood that these examples are only used to illustrate the present invention and not to limit the scope of the present invention. The test methods for which specific conditions are not indicated in the following examples are generally in accordance with conventional conditions, or in accordance with the conditions suggested by the manufacturer. All percentages and parts are by weight unless otherwise indicated.

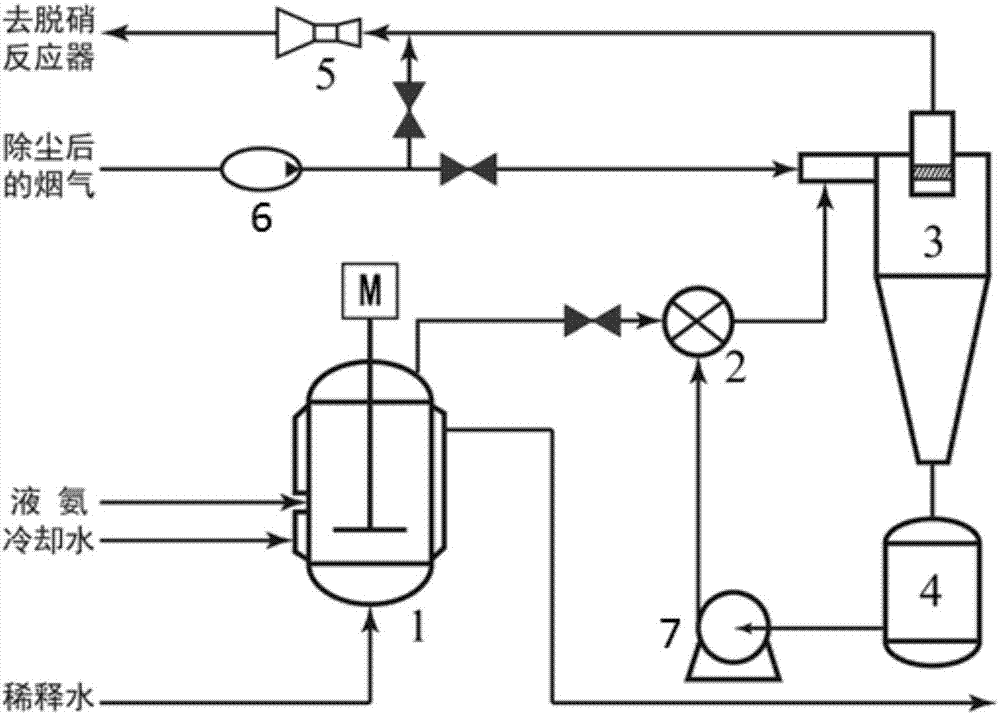

[0034] In the ammonia vaporization system of the pulverized coal furnace denitrification system of a 330MW scale power plant unit, according to the method of the present invention, flue gas reuse is used as the continuous phase to perform low-energy ammonia vaporization. The specific operation process and effects are described as follows:

[0035] 1. Material properties and related parameters

[0036] The temperature of recycled flue gas is 115°C,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap