Sodium ion battery positive electrode material containing ferric acid nickel porous nanotubes and preparation method of sodium ion battery positive electrode material

A sodium-ion battery and cathode material technology, applied in battery electrodes, nanotechnology, nanotechnology, etc., can solve problems that restrict practical applications, and achieve the effects of low cost, excellent sodium storage performance, and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

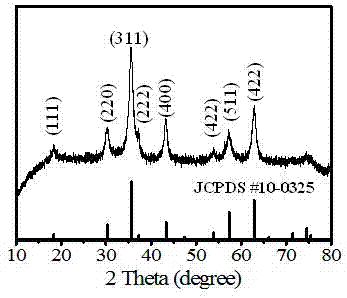

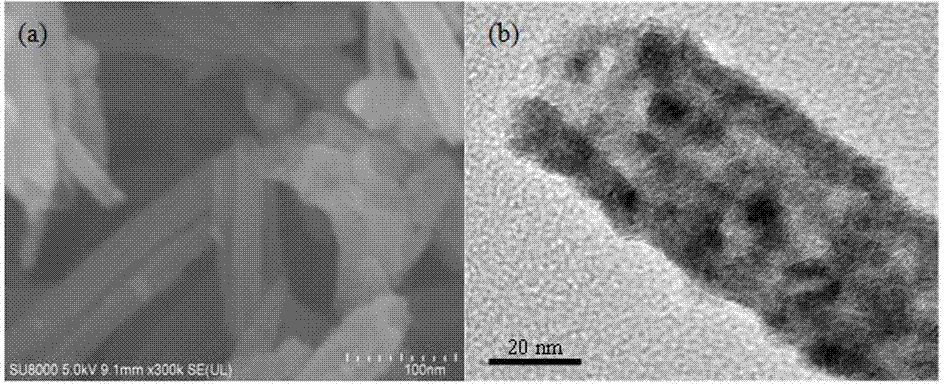

[0019] A NiFe-containing 2 o 4 The preparation method of the sodium ion battery cathode material of porous nanotube, comprises the following steps:

[0020] 1) Porous NiFe 2 o 4 Preparation of nanotubes: Dissolve 1.2 g of ferric chloride, 0.6 g of nickel nitrate and 0.3 g of terephthalic acid in 65 ml of N,N-dimethylformamide, stir well, then drop into 2 ml of 0.3 mol / L Sodium hydroxide, stirred for another 15 minutes, transferred to the reaction kettle, reacted at 150°C for 12 h, then centrifuged and washed to obtain a yellow-brown product, and finally annealed at 500°C in air to obtain the final product;

[0021] 2) Preparation of cathode material: porous NiFe 2 o 4 Nanotubes, gum arabic and acetylene black are mixed and ground at a mass ratio of 82:10:10 to prepare anode materials for sodium ion batteries.

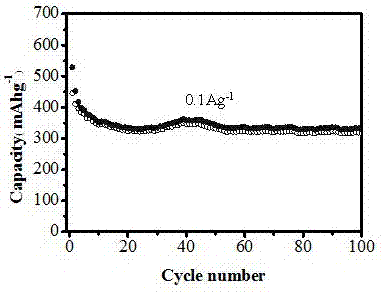

[0022] Na-ion battery assembly: Na-ion battery cathode material is evenly coated on a 1.2 cm 2 The copper sheet is used as the positive electrode, the negative e...

Embodiment 2

[0025] A NiFe-containing 2 o 4 The preparation method of the sodium ion battery cathode material of porous nanotube, comprises the following steps:

[0026] 1) Porous NiFe 2 o 4 Preparation of nanotubes: MIL-88B-Fe was prepared by one-step hydrothermal synthesis 2 Ni precursor, and then annealed in air to obtain porous NiFe 2 o 4 nanotube;

[0027] 2) Preparation of cathode material: porous NiFe 2 o 4 After mixing and grinding the nanotubes, gum arabic and acetylene black, the cathode material of the sodium ion battery is prepared.

[0028] Porous NiFe 2 o 4 The specific preparation steps of the nanotubes are as follows: dissolve 1.0 g ferric chloride, 0.5 g nickel nitrate and 0.1 g terephthalic acid into 50 ml N, N-dimethylformamide, stir well, and drop into 1 ml 0.1 mol / L sodium hydroxide, stirred for another 10 minutes, transferred to the reaction kettle, reacted at 130°C for 20 h, then centrifuged and washed to obtain a yellow-brown product, and finally annealed...

Embodiment 3

[0030] A NiFe-containing 2 o 4 The preparation method of the sodium ion battery cathode material of porous nanotube, comprises the following steps:

[0031] 1) Porous NiFe 2 o 4 Preparation of nanotubes: Dissolve 1.5 g of ferric chloride, 0.8 g of nickel nitrate and 0.6 g of terephthalic acid in 80 ml of N,N-dimethylformamide, stir well, then drop into 4 ml of 0.5 mol / L Sodium hydroxide, stirred for another 20 minutes, transferred to the reaction kettle, reacted at 170°C for 6 h, then centrifuged and washed to obtain a yellow-brown product, and finally annealed at 700°C in air to obtain the final product;

[0032] 2) Preparation of cathode material: porous NiFe 2 o 4 After mixing and grinding the nanotubes, gum arabic and acetylene black, the cathode material of the sodium ion battery is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com