Method for degrading organic pollutants in wastewater by catalyzing persulfate

A technology of organic pollutants and persulfate, applied in water pollutants, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the problems of high cost, secondary pollution of metal ions, high energy consumption, etc., and achieve long life , good stability and high degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

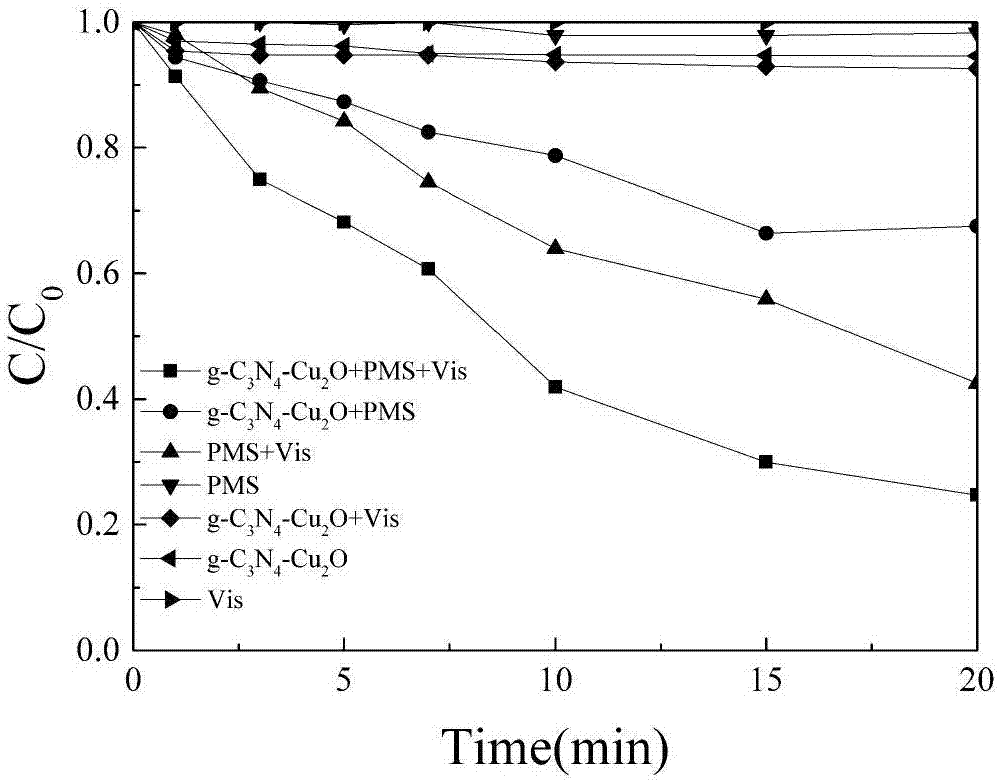

[0037] Wherein, the composite catalyst g-C 3 N 4 -Cu 2 O preparation methods include:

[0038] providing a first solution comprising Cu in a dissolved state 2+ ;

[0039] Add g-C to the first solution 3 N 4 , stirred, sonicated to obtain a suspension;

[0040] Add xylitol to the suspension under stirring, adjust the pH value to 10-12, and stir to obtain a mixed solution;

[0041] Heating the mixed solution to 150-200°C in a high-pressure reaction vessel, reacting at a constant temperature for 25-35 hours, and cooling naturally to obtain a reactant;

[0042] The cooled reactant was separated by suction filtration to obtain a solid product, which was washed and vacuum-dried;

[0043] The solid product is heated to 150-250°C under the protection of the atmosphere and kept at a constant temperature for 1h-3h to obtain g-C 3 N 4 -Cu 2 O composite catalyst.

[0044] The persulfates are selected from monopersulfates and complexes of monopersulfates, and peroxodisulfates a...

Embodiment 1

[0052] Raw Materials and Reagents

[0053] Dicyandiamide (C 2 h 4 N 4 ), copper sulfate pentahydrate (CuSO 4 ·5H 2 O), sodium hydroxide (NaOH), hydrochloric acid (HCl), tert-butanol (C 4 h 10 O), p-benzoquinone (C 6 h 4 o 2 ), disodium edetate (C 10 h 14 N 2 Na 2 o 8 ) were of analytical grade (AR), purchased from Sinopharm Chemical Reagent Co., Ltd.; xylitol (C 5 h 12 0 5 ), methyl orange (C 14 h 14 N 3 NaO 3 S), rhodamine B, methylene blue, etc. were of analytical grade (AR), purchased from Shanghai Aladdin Biochemical Technology Co., Ltd.

[0054] g-C 3 N 4 preparation of

[0055] Preparation of g-C by High Temperature Pyrolysis of Dicyandiamide 3 N 4 . Weigh 4g of dicyandiamide and place it in a corundum crucible with a cover, put the crucible in a muffle furnace, and place it in an air atmosphere at 2k / min -1 The heating rate was programmed to raise the temperature to 550°C and keep it warm for 4 hours. After the product was naturally cooled, th...

Embodiment 2

[0062] g-C not pre-protonated 3 N 4 preparation of

[0063] The g-C 3 N 4 The preparation method includes: weighing 4g of dicyandiamide and placing it in a corundum crucible with a cover, putting the crucible into a muffle furnace, and heating it up to 550°C at a heating rate of 2k / min in an air atmosphere, and keeping it warm for 4h , after the product was naturally cooled, the obtained yellow powder was ground for 30 min, and the obtained product was ground for later use.

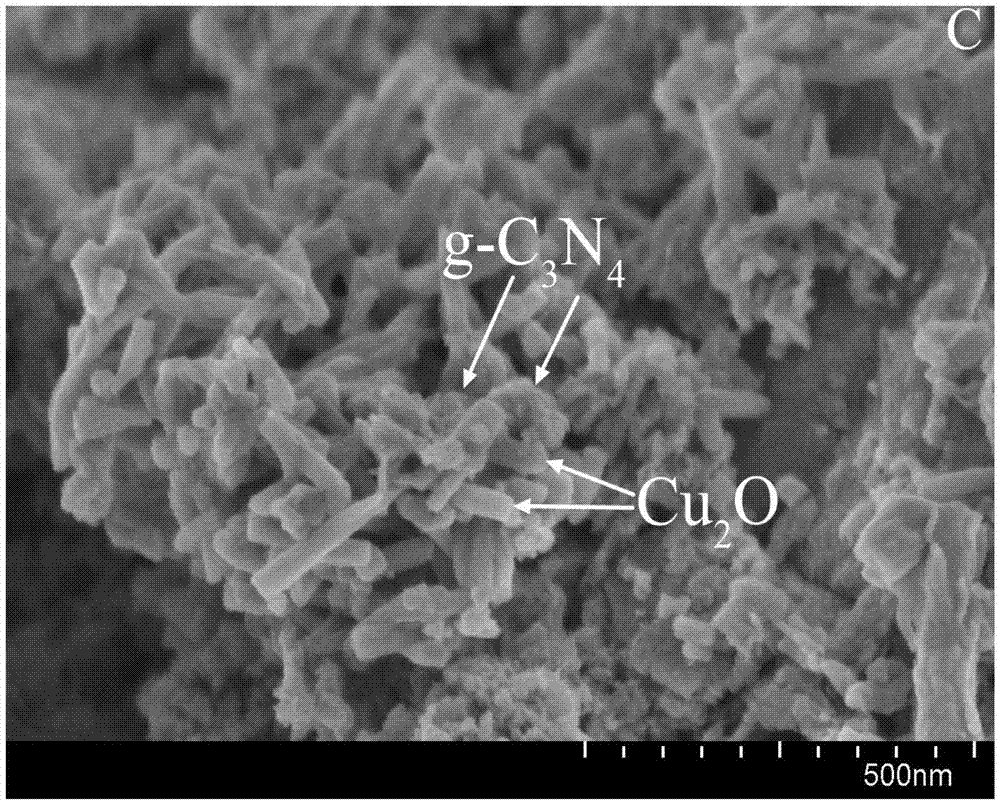

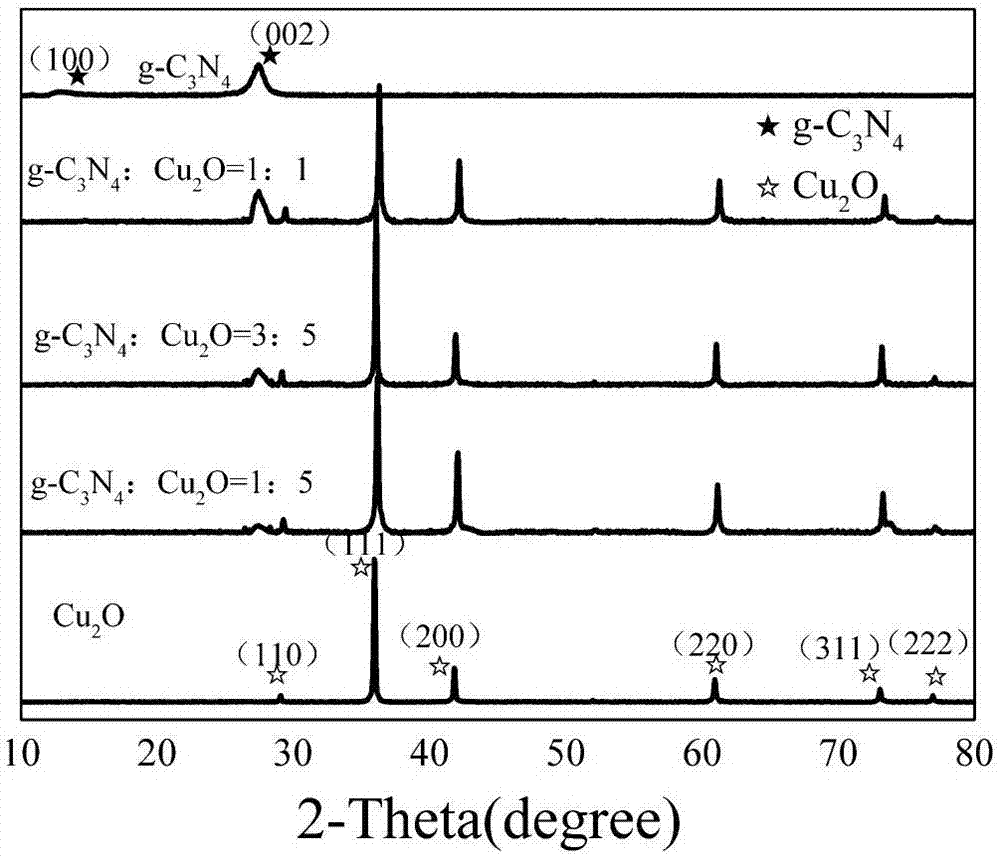

[0064] g-C 3 N 4 -Cu 2 Preparation of O composite catalyst

[0065] The g-C 3 N 4 grow to Cu 2 O surface, the specific steps are as follows: first, 1.25g CuSO 4 ·5H 2 O was added to 40mL deionized water, when the solution turned dark blue, continue to add g-C to the above solution 3 N 4 The powder was magnetically stirred for 2 h and then ultrasonicated for 2 h to obtain a homogeneous suspension (g-C 3 N 4 with Cu 2 The mass ratio of O is 1:1), then under the condition of magnetic stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com