Testing method of content of nickel in cathode material for lithium ion battery

A technology for lithium-ion batteries and positive electrode materials, which is applied in the field of nickel content testing, can solve the problems of complex composition of positive electrode materials, different test results, and inconsistent color discrimination at the end point, and achieves uncomplicated operation process, high accuracy, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

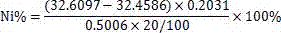

Embodiment 1

[0036] The test method is as follows:

[0037] S01: Weigh 0.5006 g of lithium-ion battery positive electrode material into a 150 mL beaker, add acid to dissolve, heat and evaporate to 5 mL.

[0038] The process of adding acid to dissolve the positive electrode material of the lithium-ion battery is as follows: first, use hydrochloric acid solution to dissolve at 100°C for 20 minutes, and then add concentrated nitric acid to continue dissolving until the sample is completely dissolved. The hydrochloric acid solution is a solution with a volume ratio of concentrated hydrochloric acid to water of 1:1, and the dosage ratio of positive electrode material, hydrochloric acid solution, and concentrated nitric acid is 1g:50mL:30mL, that is, add 25mL of the above hydrochloric acid solution and 15mL of concentrated nitric acid.

[0039] S02: Add 10mL of concentrated nitric acid to the 5mL test solution prepared above, heat to boil, then add 1g of potassium chlorate in 3 times, shake the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com