A minimum loss control method for surface-mounted permanent magnet synchronous motors

A permanent magnet synchronous motor, loss control technology, applied in motor generator control, electronic commutation motor control, control system and other directions, can solve problems such as insufficient motor efficiency, difficult adjustment of regulator parameters, and insufficient system response speed. , to ensure fast dynamic response, small steady-state loss, and steady-state accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0041] According to the above detailed introduction to the minimum loss control method of the surface-mounted permanent magnet synchronous motor, the specific implementation of the present invention will be described below by taking the minimum loss control of a surface-mounted permanent magnet synchronous motor whose parameters are shown in Table 1 as an example. .

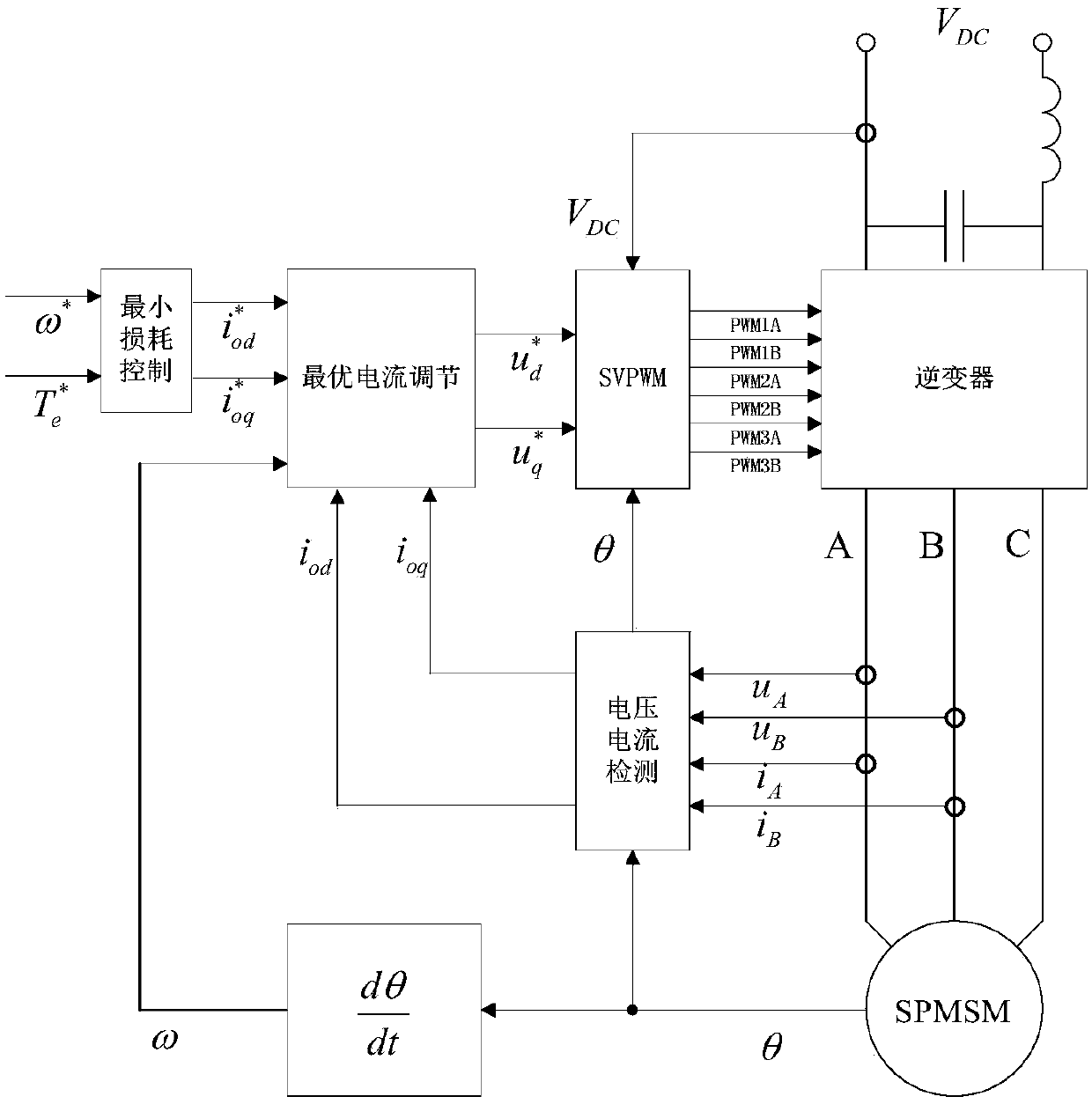

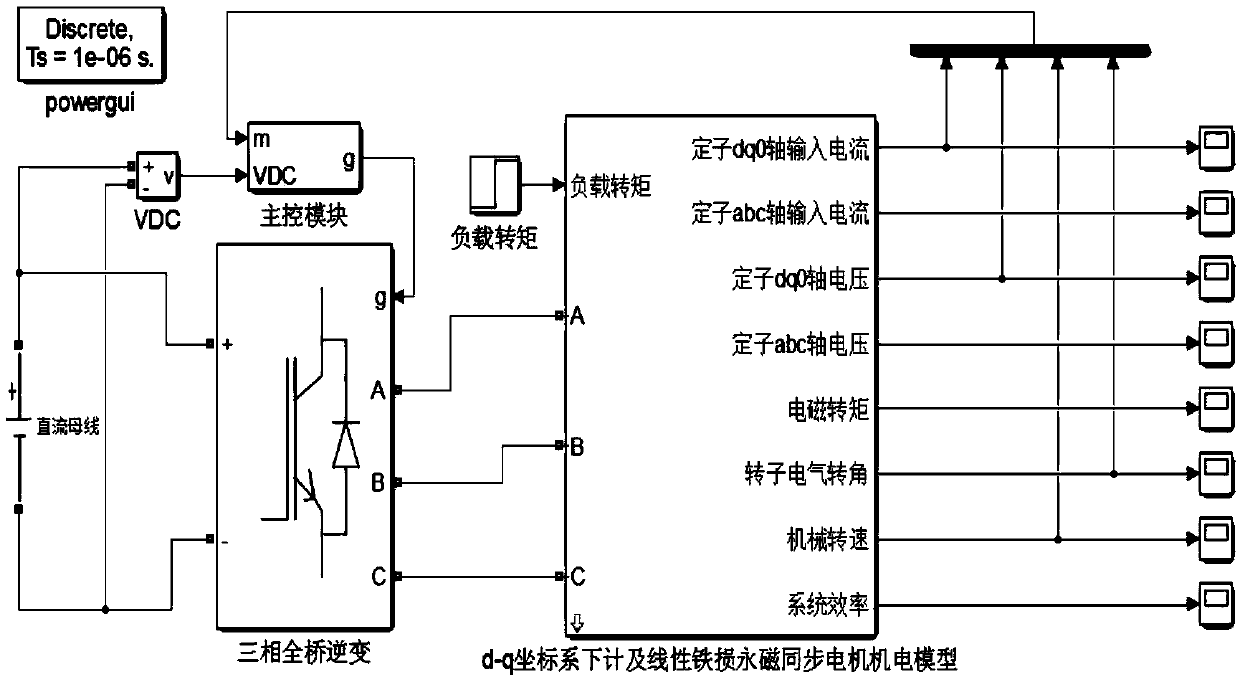

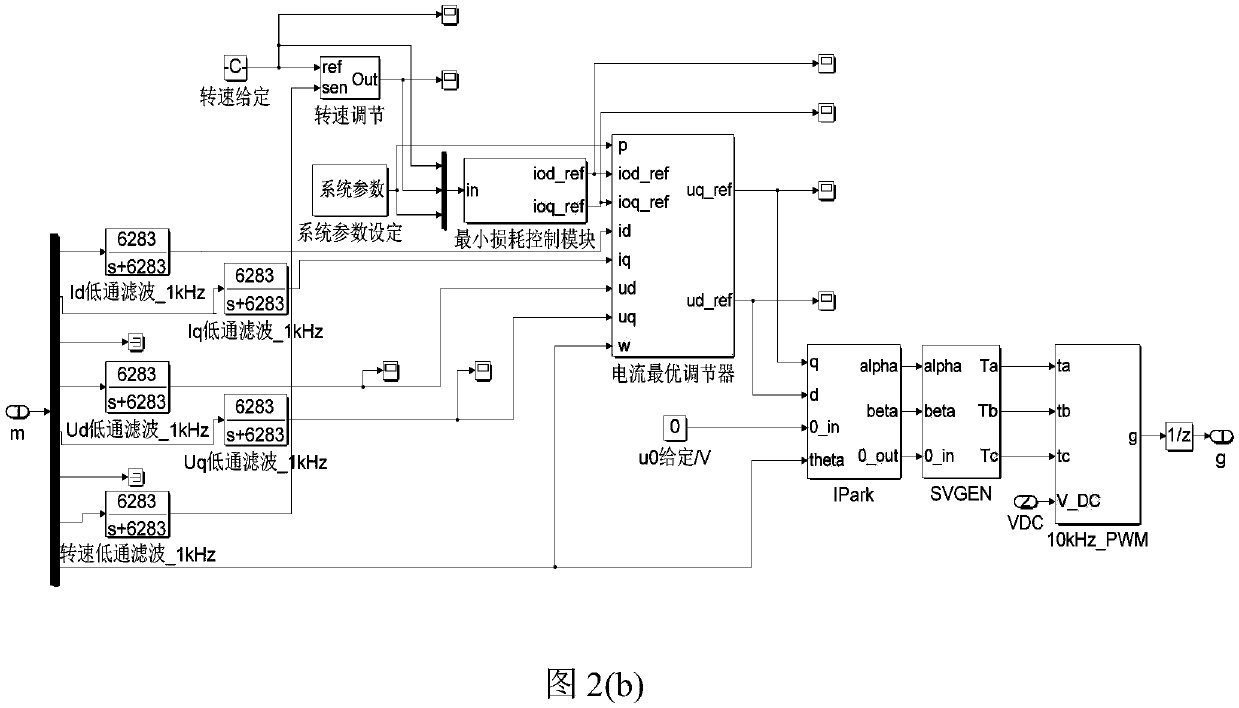

[0042] according to figure 1 The schematic diagram of the minimum loss control of surface-mounted permanent magnet synchronous motor based on the loss model is shown. The simulation model of the minimum loss control system of surface-mounted permanent magnet synchronous motor is built on the MATLAB / SIMULINK simulation software, as shown in figure 2 As shown in (a), the internal structure of the main control module is as follows figure 2 (b) Shown, the inverter switch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com