Method for compounding 2,4,6-trimethylbenzoyl-diphenylphosphine oxide through 'one-pot process'

A technology of trimethylbenzoyl and diphenylphosphine oxide, which is applied in chemical instruments and methods, organic chemistry, compounds of Group 5/15 elements of the periodic table, etc., and can solve the problem of total yield decline and post-processing steps Many problems, to achieve the effect of low cost, simple operation, and meet market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

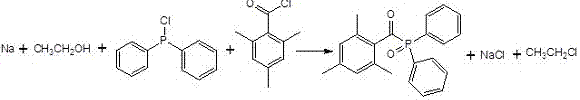

Image

Examples

Embodiment 1

[0022] In a 100ml reaction flask, add 25g of toluene and 3.45g of metal sodium particles (0.15mol), stir, then add 6.9g of ethanol (0.15mol) dropwise, and keep the temperature at 50-55°C during the dropwise addition. After the dropwise addition, stir for 2 hours, add 29.8 g (0.135 mol) of diphenylphosphine chloride dropwise to the reaction system, control the temperature at -10 to 0°C, after the dropwise addition, stir for 1 hour, continue to drop 2, 24.6g (0.135mol) of 4,6-trimethylbenzoyl chloride, the temperature was controlled at 70-75°C during the dropwise addition, and then stirred for 5h.

[0023] After the reaction was completed, 15 g of water was added to the reaction mass, stirred for 1 h, and allowed to stand for stratification. The obtained organic phase was adjusted to a pH value of 7 to 8 with saturated aqueous sodium bicarbonate solution, and the aqueous phase was separated, and the organic phase was washed and layered with water to obtain the organic phase. Pha...

Embodiment 2

[0025] In a 100ml reaction bottle, add 30g of xylene and 3.45g of metal sodium particles (0.15mol), stir, and add 6.9g (0.15mol) of ethanol dropwise, keeping the temperature at 55-60°C during the dropwise addition. After the dropwise addition, stir for 2h, add 30.9g (0.14mol) of diphenylphosphine chloride dropwise to the reaction system, control the temperature at -5~5°C, after the dropwise addition, stir for 1h, continue to dropwise add 2, 27.4g (0.15mol) of 4,6-trimethylbenzoyl chloride, the temperature was controlled at 75-80°C during the dropwise addition, and stirred for another 5h.

[0026] After the reaction was completed, 15 g of water was added to the reaction mass, stirred for 1 h, and allowed to stand for stratification. The obtained organic phase was adjusted to a pH value of 7 to 8 with saturated aqueous sodium bicarbonate solution, and the aqueous phase was separated, and the organic phase was washed and layered with water to obtain the organic phase. Phase dehyd...

Embodiment 3

[0028] In a 100ml reaction flask, add 32g of toluene and 3.45g of metal sodium particles (0.15mol), stir, and add 6.9g of ethanol (0.15mol) dropwise, keeping the temperature at 65-70°C during the dropwise addition. After the dropwise addition, stir for 2h, add 33.1g (0.15mol) of diphenylphosphine chloride dropwise to the reaction system, control the temperature at 5-10°C, after the dropwise addition, stir for 1h, continue to dropwise add 2,4 , 30.1g (0.16mol) of 6-trimethylbenzoyl chloride, the temperature was controlled at 70-75°C during the dropwise addition, and stirred for another 5h.

[0029] After the reaction was completed, 15 g of water was added to the reaction mass, stirred for 1 h, and allowed to stand for stratification. The obtained organic phase was adjusted to a pH value of 7 to 8 with saturated aqueous sodium bicarbonate solution, and the aqueous phase was separated, and the organic phase was washed and layered with water to obtain the organic phase. Phase dehy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com