Nonmetal barrier anti-explosion material and preparation method thereof

A technology that blocks explosion-proof materials and non-metals. It is applied in the direction of textiles, papermaking, containers, packaging, etc. It can solve the problems of easy failure, uncoordinated stability and mechanical properties, etc., so as to improve explosion suppression performance, increase service life, The effect of improving product toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

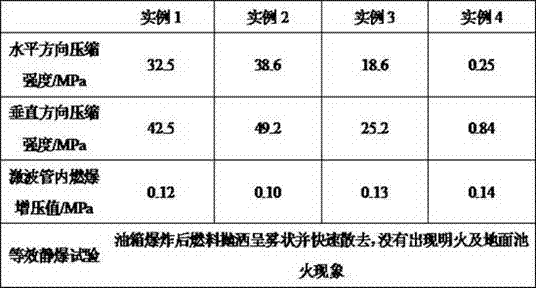

Examples

example 1

[0023]In parts by weight, pour 4 parts of polyvinyl alcohol, 6 parts of chitosan, 10 parts of gluten, and 0.1 part of sodium alginate into a beaker filled with 100 parts of water at a temperature of 20°C, and stir with a glass rod After swelling for 30 minutes, move the beaker into a water bath, heat and stir for 20 minutes at a temperature of 85°C, and wait for natural cooling to room temperature to obtain a spinning solution, which is then transferred to a high-voltage electrostatic spinning machine for spinning The filament voltage is 20kV, the temperature is 32°C, the propulsion speed is 0.3mm / s, and the receiving distance is 8cm, and the composite fiber is obtained by electrospinning, and the obtained composite fiber is mixed with a mass fraction of 80% ethanol solution according to the mass ratio of 1:20 mixing, ultrasonic dispersion at 40kHz frequency for 20min, then dropwise adding tetraethyl orthosilicate 0.8 times the weight of the composite fiber into the ethanol sol...

example 2

[0025] In parts by weight, pour 6 parts of polyvinyl alcohol, 8 parts of chitosan, 20 parts of gluten, and 0.3 parts of sodium alginate into a beaker filled with 120 parts of water at a temperature of 25 ° C, and stir with a glass rod After swelling for 45 minutes, move the beaker into a water bath, heat and stir for 40 minutes at a temperature of 90°C, and wait for natural cooling to room temperature to obtain a spinning solution, which is then transferred to a high-voltage electrostatic spinning machine for spinning The filament voltage is 22kV, the temperature is 38°C, the propulsion speed is 0.5mm / s, and the receiving distance is 10cm, and the composite fiber is obtained by electrospinning, and the obtained composite fiber is mixed with a mass fraction of 85% ethanol solution according to the mass ratio of 1:40 mixing, ultrasonic dispersion at 40kHz frequency for 40min, then dropwise adding tetraethyl orthosilicate which is 1.0 times the weight of the composite fiber to the...

example 3( comparative example 1

[0027] Commercially available spherical non-metallic barrier explosion-proof materials are used

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com