Preparation method and applications of polyelectrolyte nano particle/NaA molecular sieve composite film capable of being protonated

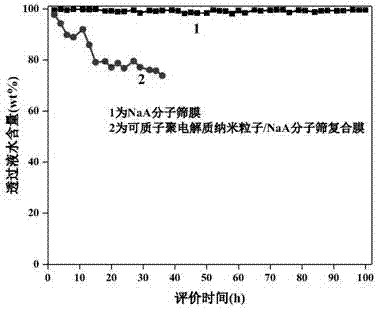

A polyelectrolyte and nanoparticle technology, which is applied in the field of membrane separation, can solve problems such as separation performance degradation and molecular sieve skeleton collapse, and achieve the effects of improving stability, not easy to peel or swell, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation condition and method of a protonatable polyelectrolyte nanoparticle / NaA composite film, comprising the steps of:

[0032] (1) Rinse the molecular sieve membrane with a length of about 5 cm with deionized water, soak it in 1 g / L dopamine solution for 12 hours, and then dry it in an oven at 30°C.

[0033] (2) preparation concentration is 0.02wt% sodium polyethylene sulfonate and pH is 4, concentration is the chitosan aqueous solution of 0.02wt%, by the ratio of sulfonate amino anion and cation molar ratio 0.2:1 the two are mixed, through After precipitation, washing and vacuum drying, the protonatable polyelectrolyte nanoparticle material is obtained.

[0034] (3) 0.15 g of protonatable polyelectrolyte nanoparticles was weighed and dissolved in 99.85 g of acetic acid with a volume fraction of 1%, and stirred and dissolved for 8 hours to obtain a solution with a concentration of 0.15 wt%.

[0035] (4) Immerse the molecular sieve membrane in (1) in (3) for 30...

Embodiment 2

[0038] A preparation condition and method of a protonatable polyelectrolyte nanoparticle / NaA composite film, comprising the steps of:

[0039] (1) Rinse the molecular sieve membrane with a length of about 5 cm with deionized water, soak it in 5 g / L dopamine solution for 24 hours, and then dry it in an oven at 40°C.

[0040] (2) preparation concentration is 2wt% sodium polystyrene sulfonate and pH is 8, concentration is the chitosan aqueous solution of 2wt%, by the ratio of sulfonate amino anion and cation molar ratio 0.8:1 the two are mixed, through precipitation , washing, and vacuum drying to obtain protonatable polyelectrolyte nanoparticle materials.

[0041] (3) 1.5 g of protonatable polyelectrolyte nanoparticles was weighed and dissolved in 98.5 g of acetic acid with a volume fraction of 2%, stirred and dissolved rapidly for 64 hours to obtain a solution with a concentration of 1.5 wt%.

[0042] (4) Soak the molecular sieve membrane in (1) in (3) for 1 min, take it out, an...

Embodiment 3

[0045] A preparation condition and method of a protonatable polyelectrolyte nanoparticle / NaA composite film, comprising the steps of:

[0046] (1) Rinse the molecular sieve membrane with a length of about 5 cm with deionized water, soak it in 1 g / L dopamine solution for 24 hours, and then dry it in an oven at 40°C.

[0047] (2) preparation concentration is that the dextran sodium sulfate of 0.02wt% and pH are 6, concentration is the chitosan aqueous solution of 0.02wt%, by the ratio of 0.8:1 molar ratio of sulfate radical amino anion and cation molar ratio both are mixed, through After precipitation, washing and vacuum drying, the protonatable polyelectrolyte nanoparticle material is obtained.

[0048] (3) 1.5 g of protonatable polyelectrolyte nanoparticles was weighed and dissolved in 98.5 g of acetic acid with a volume fraction of 2%, stirred and dissolved rapidly for 48 hours to obtain a solution with a concentration of 1.5 wt%.

[0049] (4) Soak the molecular sieve membra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com