Method for synthesizing Beta molecular sieve through hydrothermal treatment

A technology of hydrothermal treatment and synthesis method, applied in the direction of molecular sieve catalyst, molecular sieve and base exchange compound, chemical instrument and method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Exchange 1.0 g of Beta molecular sieve (on a dry basis) synthesized without organic templates with 15 g of an aqueous solution containing 3.0 g of inorganic ammonium salt at 100 ° C for 20 minutes, and then use 15 g of aqueous solution containing 1.0 g (NH 4 ) 2 SO 4 The aqueous solution was exchanged once, filtered, and washed to remove SO 4 2- , dried at 100°C.

[0025] (2) Intermediate roasting: Place the sample after (1) exchange in a muffle furnace, raise the temperature to 510° C. at room temperature, and keep the temperature constant for 3 hours.

[0026] (3) Use 60g of roasted zeolite containing 3.0g (NH 4 ) 2 SO 4 The aqueous solution was exchanged at 100°C for 30 minutes, filtered and repeated exchanged once, filtered, and washed to remove SO 4 2- ion.

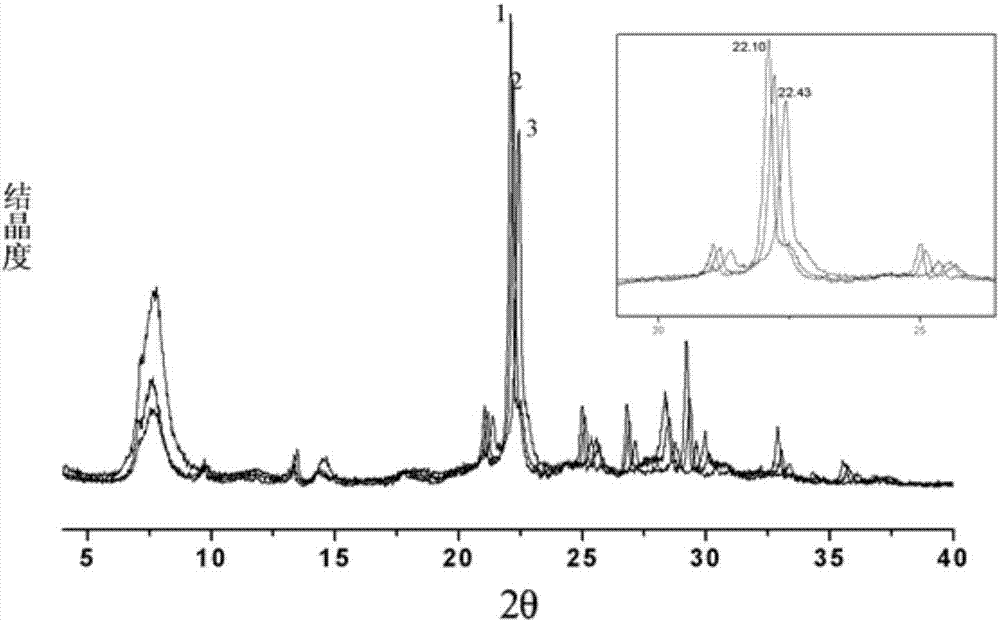

[0027] (4) Press the above-mentioned filter cake, place it in a crucible, put it in a muffle furnace, heat it up to 560°C, 650, and 760°C for 1 hour and bake it for 4 hours.

Embodiment 2

[0029] (1) Exchange 1.0 g of Beta (on a dry basis) synthesized without an organic template with 15 g of an aqueous solution containing 3.0 g of inorganic ammonium salt at 100° C. for 20 minutes, and then filter it with 15 g of an aqueous solution containing 1.0 g (NH 4 ) 2 SO 4 The aqueous solution was exchanged once, filtered, and washed to remove SO 4 2- , dried at 100°C.

[0030] (2) Intermediate roasting: Place the sample after (1) exchange in a muffle furnace, raise the temperature to 510° C. at room temperature, and keep the temperature constant for 3 hours.

[0031] (3) Use 60g of roasted zeolite containing 3.0g (NH 4 ) 2 SO 4 The aqueous solution was exchanged at 100°C for 30 minutes, filtered and repeated exchanged once, filtered, and washed to remove SO 4 2- ion.

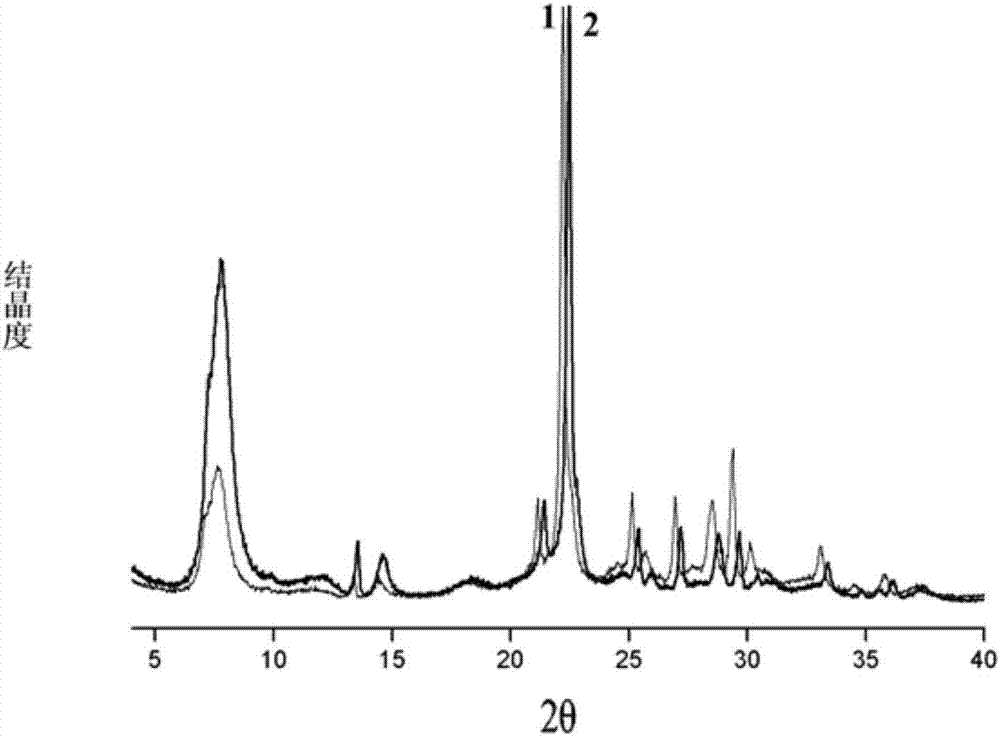

[0032] (4) Put the exchanged zeolite into a roasting furnace and roast for 3-8 hours at 560, 650, 750 and 800° C. under the condition of 100% water vapor atmosphere.

Embodiment 3

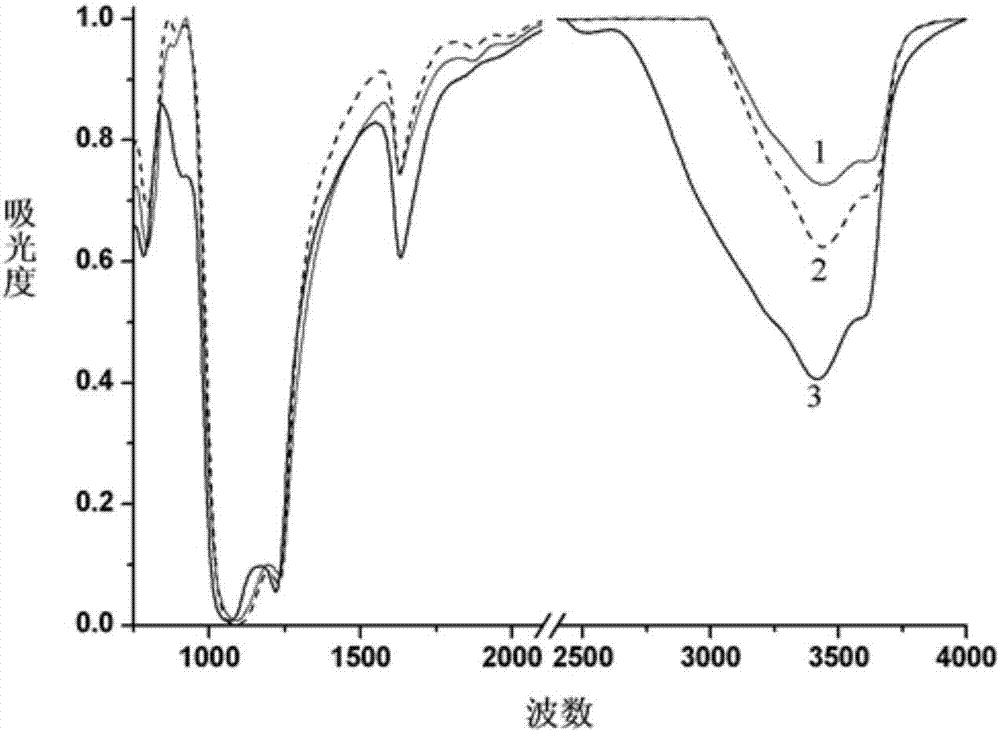

[0034] Exchange 1.0 g of Beta (on a dry basis) synthesized without an organic template with 50 g of an aqueous solution containing 4.0 g of ammonium nitrate at 80°C for 2 hours, filter and wash with deionized water, dry it, and place it in a muffle furnace , heat up to 500°C and bake for 3 hours. Repeat the above steps once to obtain a hydrogen-type molecular sieve containing little sodium.

[0035] The prepared sample was then exchanged with 50 g of an aqueous solution containing 4.0 g of ammonium nitrate at 80° C. for 1 hour, and the wet sample was placed in a roasting furnace for 1 hour at 800° C. under a 100% water vapor atmosphere.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com