Raw material wine brewing technology

A process and raw material technology, which is applied in the fields of food processing and wine making, can solve the problems of high proficiency requirements for workers, unfavorable reuse of distiller's grains, and high labor demand, and achieve the goals of improving wine yield, saving manpower, and saving energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

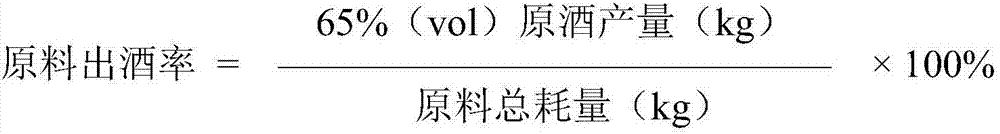

Image

Examples

Embodiment 1

[0047] A raw material wine making process, including the following steps: raw material crushing → batching fermentation → distilling wine → bottling; wherein:

[0048] (1) The raw material is pulverized, and the raw material is selected from grains such as rice, corn, wheat, sorghum, and the grain raw material is pulverized to a fineness of 100 mesh;

[0049] (2) Fermentation of ingredients, the selected volume is 0.2-1.0m 3 The pottery vat, plastic bucket, aluminum bucket or cement tank is used as a fermenter. First add water to the fermenter, then add the crushed grain raw materials, stir while adding, until the lumps and lumps are eliminated, and finally add the koji. The distiller's koji is made from the following raw materials in parts by weight: 8 saccharomyces cerevisiae active yeast, 14 rhizopus koji, 60 niger enzymes, 2 cellulase, 1.5 Lactobacillus acidophilus, 4 beta-amylase, 1.5 aroma active yeast ;The temperature of the water is 20°C, the ratio of grain raw materi...

Embodiment 2

[0053] A raw material wine making process, including the following steps: raw material crushing → batching fermentation → distilling wine → bottling; wherein:

[0054] (1) The raw material is pulverized, and the raw material is selected from grains such as rice, corn, wheat, sorghum, and the grain raw material is pulverized to a fineness of 80 mesh;

[0055] (2) Fermentation of ingredients, the selected volume is 0.2-1.0m 3 The pottery vat, plastic bucket, aluminum bucket or cement tank is used as a fermenter. First add water to the fermenter, then add the crushed grain raw materials, stir while adding, until the lumps and lumps are eliminated, and finally add the koji. The distiller's koji is made from the following raw materials in parts by weight: 8 saccharomyces cerevisiae active yeast, 14 rhizopus koji, 60 niger enzymes, 2 cellulase, 1.5 Lactobacillus acidophilus, 4 beta-amylase, 1.5 aroma active yeast , nitrifying bacteria 2.2; the temperature of the water is 24°C, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com