Poling method for relaxor ferroelectric single crystal as nonlinear optical material

A technology of relaxor ferroelectric single crystal and nonlinear optics, which is applied in the fields of optical information processing and optical communication, can solve the problems of easy cracking of crystals and difficulty in obtaining large sizes, and achieve large electro-optic coefficients, highly monodomain optical properties, and optical properties strong folding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

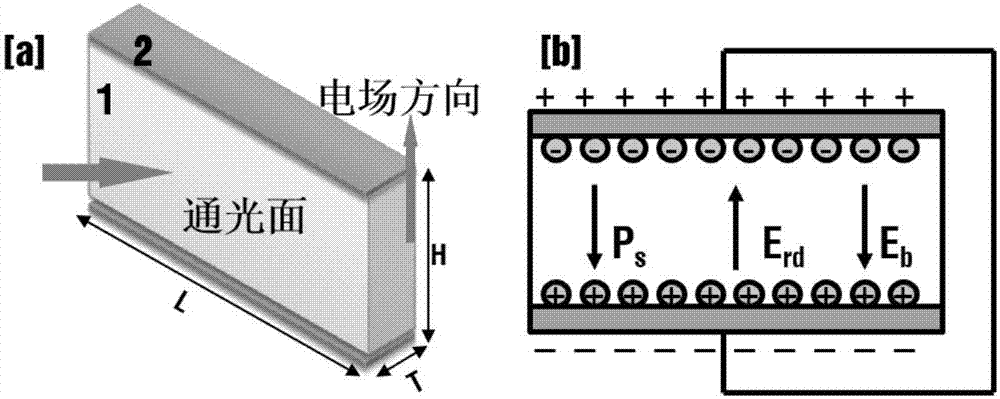

[0046] (1) Crystal processing

[0047] (a) The [111] oriented trigonal phase PMNT system relaxor ferroelectric single crystal selects a crack-free, well-crystallized region, three-dimensionally oriented, and cuts into the shape required for the experiment 6*2*6 mm (L*T *H), grinding and polishing plane 1 and its parallel planes, such as figure 1 (a) shown. Grind lightly with sandpaper until there are no obvious scratches, and then polish it on a polishing machine until it is close to an optical plane (flatness is less than 1 μm) to obtain the sample required for the experiment.

[0048] (2) Annealing process

[0049] (a) Annealing the relaxed ferroelectric single crystal of the trigonal phase PMNT system with the [111] crystal orientation described in (1-a) to eliminate the stress generated during growth, cutting, polishing and ferroelectric phase formation . The crystal was placed in an atmosphere furnace, and the temperature was raised to 800° C. at a rate of 4° C. per m...

Embodiment 2

[0058] (1) Crystal processing

[0059] (a) The [110] oriented orthorhombic phase PIMNT system relaxor ferroelectric single crystal selects a crack-free and well-crystallized region, three-dimensionally oriented, and cuts into the shape required for the experiment 4*1*3 mm (L* T*H), grind and polish plane 1 and its parallel planes, such as figure 1 (a) shown. Grind lightly with sandpaper until there are no obvious scratches, and then polish it on a polishing machine until it is close to an optical plane (flatness is less than 1 μm) to obtain the sample required for the experiment.

[0060] (2) Annealing process

[0061] (a) Anneal the relaxation ferroelectric single crystal of the orthorhombic phase PIMNT system with the [110] crystal orientation described in (1-a), to eliminate the generated during growth, cutting, polishing and ferroelectric phase formation stress. The crystal was placed in an atmosphere furnace, and the temperature was raised to 500°C at a rate of 0.2°C ...

Embodiment 3

[0070] (1) Crystal processing

[0071] (a) Select a crack-free and well-crystallized region of the relaxation ferroelectric single crystal of the tetragonal PIMNT system with the [001] crystal orientation, and cut it into the shape required for the experiment 2*1*2 mm (L*T *H), grinding and polishing plane 1 and its parallel planes, such as figure 1 (a) shown. Grind lightly with sandpaper until there are no obvious scratches, and then polish it on a polishing machine until it is close to an optical plane (flatness is less than 1 μm) to obtain the sample required for the experiment.

[0072] (2) Annealing process

[0073] (a) Annealing the relaxed ferroelectric single crystal of tetragonal phase PIMNT system with the [001] crystal orientation described in (1-a) to eliminate the stress generated during growth, cutting, polishing and ferroelectric phase formation . The crystal was placed in an atmosphere furnace, the temperature was raised to 750°C at a rate of 1°C / min, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electro-optic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com