Method of removing seeds in passion fruit pulp

A technology of passion fruit and passion fruit juice, which is applied in the direction of food science, food preservation, and the function of food ingredients, etc., and can solve the problems that passion fruit pulp is prone to browning reaction, increases the production cost of pulp, and reduces the quality of pulp, etc. , achieve significant biological activity and health care function, reduce low activity and improve antiseptic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

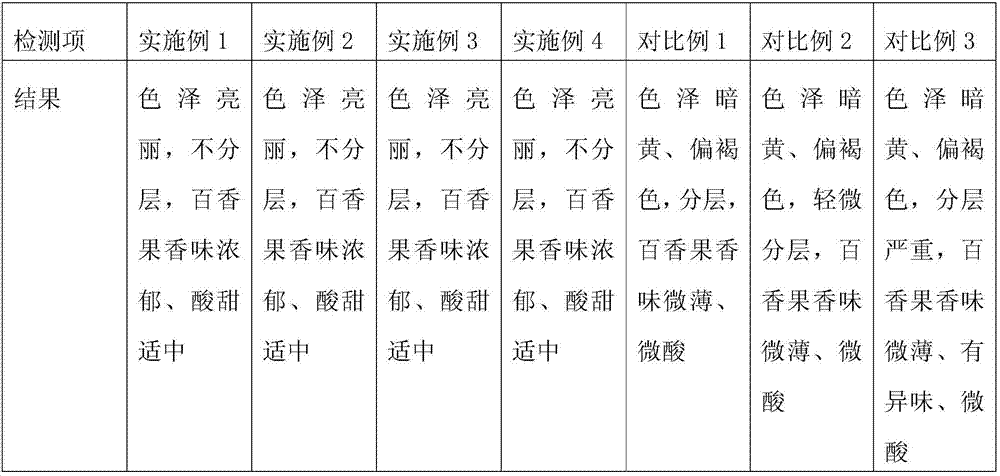

Examples

Embodiment 1

[0030] A method for deseeding passion fruit pulp comprises the following steps:

[0031] Add an enzyme preparation consisting of amylase, cellulase, pectinase, and β-glucosidase to passion fruit pulp for enzymolysis; place the enzymatically hydrolyzed passion fruit pulp in a 40-mesh sieve, and use 0.05% by mass percent of the stabilizer composed of sodium alginate, carboxymethyl cellulose and xanthan gum, 0.5% of the anti-browning agent composed of bromelain, propolis and laccase, 5% of the same mass ratio of rice Root polysaccharides, rice bran polysaccharides, guava polysaccharides, konjac polysaccharides, spirulina polysaccharides are washed with high-pressure water to obtain passion fruit seeds and passion fruit juice; The bacteria condition is a pressure of 700Mpa, and after the sterilization time is 30min, the finished product of passion fruit juice is obtained; the pressure of the high-pressure water is 30Mpa.

Embodiment 2

[0033] A method for deseeding passion fruit pulp comprises the following steps:

[0034] Add β-glucosidase to the passion fruit pulp for enzymolysis; the passion fruit pulp after enzymolysis is placed in a 40-mesh sieve, using 0.01% by mass percentage of sodium alginate and carboxymethyl cellulose 0.1% anti-browning agent consisting of cucurbit leaf extract, propolis and laccase in a mass ratio of 1:3:5, 3% rice root polysaccharide and rice bran in a mass ratio of 1:5:5 High-pressure water washing of plant polysaccharides composed of polysaccharides and konjac polysaccharides to separate passion fruit seeds and passion fruit juice; after the passion fruit juice is prepared, it is sterilized by ultra-high pressure, the sterilization condition is a pressure of 500Mpa, and the sterilization time is 30min. , to obtain the finished product of passion fruit juice; the pressure of the high-pressure water is 20Mpa;

[0035] Wherein, the cucurbit leaf extract is prepared by the follow...

Embodiment 3

[0037] A method for deseeding passion fruit pulp comprises the following steps:

[0038] Add an enzyme preparation composed of cellulase, pectinase and β-glucosidase to passion fruit pulp for enzymolysis; place the enzymatically hydrolyzed passion fruit pulp in a 40-mesh sieve, and use 0.03% stabilizer composed of carboxymethyl cellulose, xanthan gum and propylene glycol alginate, 0.2% anti-corrosion agent composed of cucurbit leaf extract, papain, propolis and laccase in a mass ratio of 3:1:4 Browning agent, 4% high-pressure water washing of plant polysaccharides composed of guava polysaccharides, konjac polysaccharides, and spirulina polysaccharides with a mass ratio of 1:5:5, and separation to obtain passion fruit seeds and passion fruit juice; the passion fruit juice is formulated Finally, adopt ultra-high pressure sterilization, the sterilization condition is a pressure of 600Mpa, after the sterilization time is 30min, the finished product of passion fruit juice is obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com