Ginseng and semen cassiae tableted candy and preparation method thereof

A technology for compressing candy and cassia seeds, which is applied in the fields of confectionary, confectionery industry, and the function of food ingredients, etc., which can solve the problems of being easy to break, difficult to cover up the bitter taste of ginseng, and unfavorable for pressing into buccal tablets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

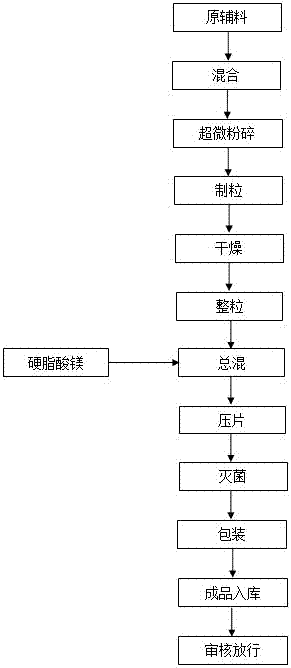

Method used

Image

Examples

Embodiment 1

[0020] (1) Selected raw and auxiliary materials: The selected materials are free from insects, pollution, mildew, and rot and deterioration, and meet the requirements of various indicators.

[0021] (2) Mixing: Except for magnesium stearate, accurately weigh the raw materials according to the following formula, and then put them into the mixer for mixing. Formula: 20% ginseng, 10% cassia seed, 20% turmeric, 25% brown sugar, 10% isomaltooligosaccharide, 5% hydroxypropyl starch, 10% cocoa powder, 2% magnesium stearate.

[0022] (3) Pulverization: The mixed materials are first coarsely powdered and then superfinely pulverized. After pulverization, the fineness of the powder shall not be lower than 100 mesh.

[0023] (4) Granulation: spray an appropriate amount of 85% ethanol on the superfine material powder, and adjust the humidity of the material to make a soft material. And put the soft material into the granulator, and select 20 mesh at the bottom of the sieve.

[0024] (5) ...

Embodiment 2

[0035] (1) Selected raw and auxiliary materials: The selected materials are free from insects, pollution, mildew, and rot and deterioration, and meet the requirements of various indicators.

[0036] (2) Mixing: Except for magnesium stearate, accurately weigh the raw materials according to the following formula, and then put them into the mixer for mixing. Formula: 10% ginseng, 5% cassia seed, 10% turmeric, 40% brown sugar, 10% isomaltooligosaccharide, 10% hydroxypropyl starch, 15% cocoa powder, 2% magnesium stearate.

[0037] (3) Pulverization: The mixed materials are first coarsely powdered and then superfinely pulverized. After pulverization, the fineness of the powder shall not be lower than 100 mesh.

[0038] (4) Granulation: spray an appropriate amount of 85% ethanol on the superfine material powder, and adjust the humidity of the material to make a soft material. And put the soft material into the granulator, and select 20 mesh at the bottom of the sieve.

[0039] (5) ...

Embodiment 3

[0050] (1) Selected raw and auxiliary materials: The selected materials are free from insects, pollution, mildew, and rot and deterioration, and meet the requirements of various indicators.

[0051] (2) Mixing: Except for magnesium stearate, accurately weigh the raw materials according to the following formula, and then put them into the mixer for mixing. Formula: 13% ginseng, 7% cassia seed, 20% mandarin turnip, 25% brown sugar, 10% isomaltooligosaccharide, 10% hydroxypropyl starch, 15% cocoa powder, 2% magnesium stearate.

[0052] (3) Pulverization: The mixed materials are first coarsely powdered and then superfinely pulverized. After pulverization, the fineness of the powder shall not be lower than 100 mesh.

[0053] (4) Granulation: spray an appropriate amount of 85% ethanol on the superfine material powder, and adjust the humidity of the material to make a soft material. And put the soft material into the granulator, and select 20 mesh at the bottom of the sieve.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com