Preparation method of magnetic mesoporous molecular sieve based nNOS-PSD-95 uncoupler surface molecularly imprinted polymer

A technology of mesoporous molecular sieve and uncoupling agent, which is applied in the directions of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc. Complex, many interfering components, and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

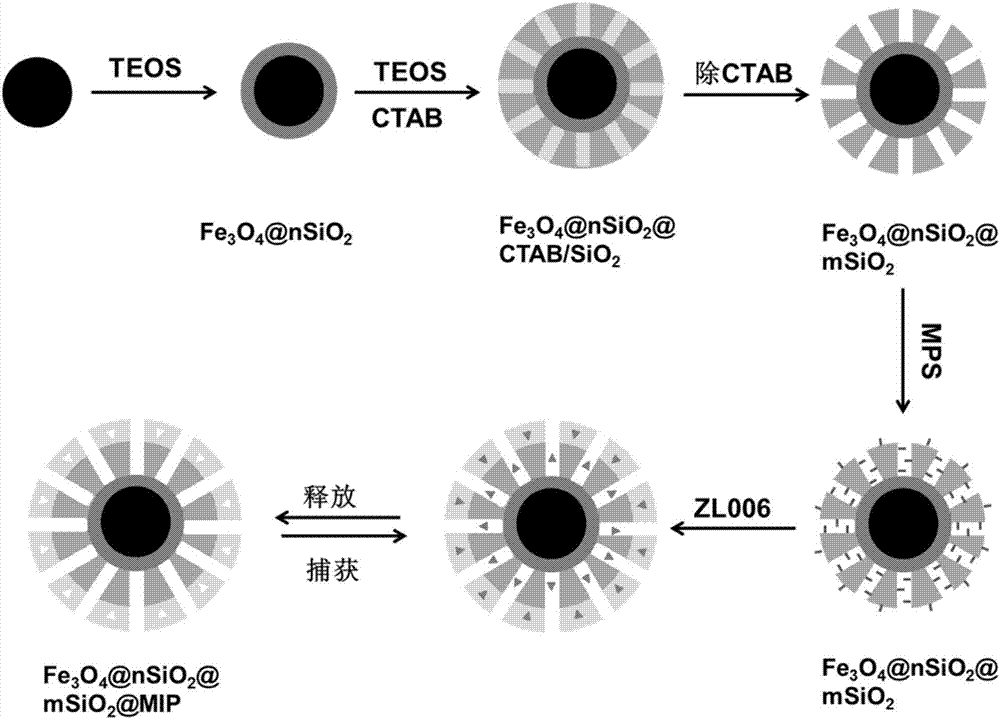

Method used

Image

Examples

Embodiment 1

[0037] (1). Weigh 2.7g FeCl 3 ·6H 2 O and 7.2g NaAc were dissolved in 100mL ethylene glycol with magnetic stirring until a uniform yellow solution was obtained, transferred to a tetrafluoroethylene autoclave, left standing at 200°C for 8h, cooled at room temperature, washed 6 times with absolute ethanol, magnetically separated, and vacuum-dried at 45°C to constant weight, get Fe 3 o4 powder.

[0038] (2). Weigh the obtained Fe 3 o 4 Ultrasonically disperse 0.1g powder in 80mL ethanol, add 20mL deionized water and 1mL concentrated ammonia water, add dropwise 0.1gTEOS to the solution under magnetic stirring, stir at room temperature for 6h, wash with ethanol and deionized water, and redisperse in 60mL ethanol and 80mL deionized water , 1g concentrated ammonia water mixed solution, add 0.3gCTAB, stir at room temperature for 30min, then dropwise add 0.4gTEOS, continue to stir for 6h, the rotation speed is 500rpm, the TEOS addition rate is one drop every 2s, and finally collect...

Embodiment 2

[0044] (1). Weigh 2.7g FeCl 3 ·6H 2 O and 7.2g NaAc were dissolved in 100mL ethylene glycol with magnetic stirring until a uniform yellow solution was obtained, transferred to a tetrafluoroethylene autoclave, left standing at 200°C for 8h, cooled at room temperature, washed 6 times with absolute ethanol, magnetically separated, and vacuum-dried at 45°C to constant weight, get Fe 3 o 4 powder.

[0045] (2). Weigh the obtained Fe 3 o 4 Ultrasonically disperse 0.1g powder in 80mL ethanol, add 20mL deionized water and 1mL concentrated ammonia water, add dropwise 0.1gTEOS to the solution under magnetic stirring, stir at room temperature for 6h, wash with ethanol and deionized water, and redisperse in 60mL ethanol and 80mL deionized water , 1g concentrated ammonia solution, add 0.3gCTAB, stir at room temperature for 30min, then dropwise add 0.4gTEOS, continue to stir for 6h, the rotation speed is 600rpm, the TEOS addition rate is one drop every 10s, and then collect the product...

Embodiment 3

[0051] (1). Weigh 2.7g FeCl 3 ·6H 2 O and 7.2g NaAc were dissolved in 100mL ethylene glycol with magnetic stirring until a uniform yellow solution was obtained, transferred to a tetrafluoroethylene autoclave, left standing at 200°C for 8h, cooled at room temperature, washed 6 times with absolute ethanol, magnetically separated, and vacuum-dried at 45°C to constant weight, get Fe 3 o 4 powder.

[0052] (2). Weigh the obtained Fe 3 o 4 Ultrasonically disperse 0.1g powder in 80mL ethanol, add 20mL deionized water and 1mL concentrated ammonia water, add dropwise 0.1gTEOS to the solution under magnetic stirring, stir at room temperature for 6h, wash with ethanol and deionized water, and redisperse in 60mL ethanol and 80mL deionized water , 1g concentrated ammonia water mixed solution, add 0.3gCTAB, stir at room temperature for 30min, then dropwise add 0.4gTEOS, continue to stir for 6h, the rotation speed is 700rpm, TEOS drop rate is one drop every 15s, and finally collect the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com