A kind of soil active agent and preparation method thereof

A soil activator and revitalization technology, which is applied in the direction of chemical instruments and methods, soil conditioning materials, calcium fertilizers, etc., can solve problems such as deterioration of the ecological environment, threats to health, and damage to soil structure, so as to rebuild soil ecological balance and improve soil quality. The utilization rate of fertilizer efficiency and the effect of improving soil activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

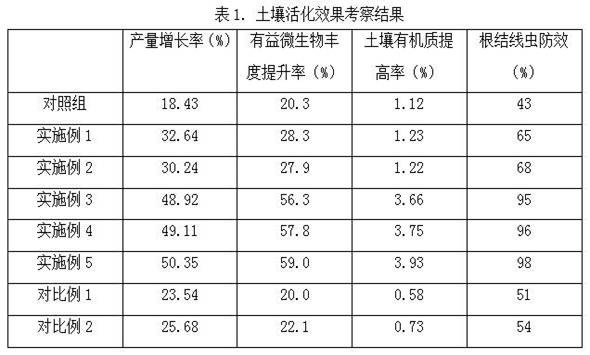

Examples

Embodiment 1

[0043] A method for preparing a soil activator, first of all, the active ingredient, nutrient mixture, binder and excipient are mixed evenly to obtain a mixed powder, and then the mixed powder is mixed with water and stirred evenly to make a semi-wet mixture, granulated, dried, i.e., a soil activator is obtained;

[0044] Wherein, the active ingredient is angelica, astragalus, ginseng production selection process removed from the rhizome residue in accordance with the mass ratio of 1: 1: 1: 1 mixed; The mixture of nutrient elements is obtained by mixing the following components: urea 1kg, potassium sulfate 1kg, ammonium nitrate 1kg, ammonium dihydrogen phosphate 1kg, fulvic acid 1kg; The binder is obtained by mixing attapulgite soil with carboxymethyl cellulose according to the mass ratio of 5: 1; The excipient is sodium compound nitrophenol.

[0045] The mass ratio of active ingredients, nutrient mixtures, binders and excipients is 55: 26: 10: 1.5.

[0046] The mass ratio of mixed ...

Embodiment 2

[0051] A method for preparing a soil activator, first of all, the active ingredient, nutrient mixture, binder and excipient are mixed evenly to obtain a mixed powder, and then the mixed powder is mixed with water and stirred evenly to make a semi-wet mixture, granulated, dried, i.e., a soil activator is obtained;

[0052] Wherein, the active ingredient is angelica, astragalus, ginseng production selection process removed from the rhizome residue in accordance with the mass ratio of 1: 1: 1: 1 mixed; The mixture of nutrient elements is obtained by mixing the following components: urea 1kg, potassium sulfate 1kg, ammonium nitrate 1kg, potassium dihydrogen phosphate 1kg, potassium humic acid 1kg; The binder is obtained by mixing attapulgite with methylcellulose according to the mass ratio of 5:1; The excipient is sodium 2,4-dinitrophenol.

[0053] The mass ratio of active ingredients, nutrient mixtures, binders and excipients is 75:10:18:0.5.

[0054] The mass ratio of mixed powder t...

Embodiment 3

[0059] A method for preparing a soil activator, first of all, the active ingredient, nutrient mixture, binder and excipient are mixed evenly to obtain a mixed powder, and then the mixed powder is mixed with water and stirred evenly to make a semi-wet mixture, granulated, dried, i.e., a soil activator is obtained;

[0060] Wherein, the active ingredient is angelica, astragalus, ginseng production selection process removed from the rhizome residue in accordance with the mass ratio of 1: 1: 1: 1 mixed; The mixture of nutrient elements is obtained by mixing the following components: urea 1kg, potassium sulfate 1kg, ammonium nitrate 1kg, ammonium dihydrogen phosphate 1kg, potassium humic acid 1kg; The binder is obtained by mixing attapulgite soil with carboxymethyl cellulose according to the mass ratio of 5: 1; The excipient is sodium compound nitrophenol.

[0061] The mass ratio of active ingredients, nutrient mixtures, binders and excipients is 55: 26: 10: 1.5.

[0062] The mass ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com