Halogen-free electronic material with high dielectric performance and preparation method of material

An electronic material and high dielectric technology, which is applied in the field of halogen-free high dielectric performance electronic materials and their preparation, can solve the problems of not achieving flame retardant effect, reducing the dielectric performance of materials, etc., to prevent insufficient curing and improve processing. performance, the effect of avoiding local defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

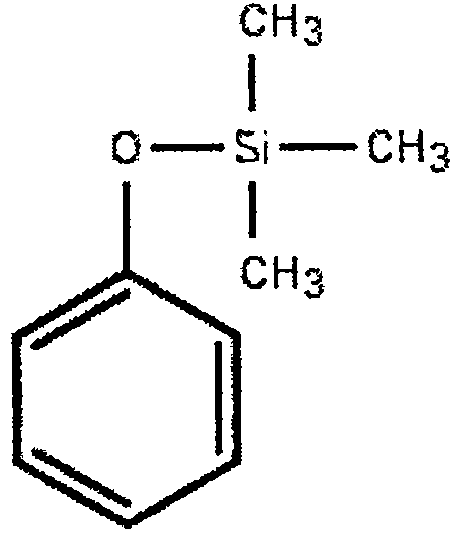

[0021] A preparation method of a halogen-free high dielectric performance electronic material, comprising the following steps: adding 4g of fullerene derivative PCBM to 4000g of cyanate ester chlorobenzene solution (25wt%), then adding 100g of maleic anhydride, and refluxing After reacting for 40 minutes, add 120g of biscarboxyphthalimide, react for 1 hour, and then dry and remove the solvent at 135°C to obtain a cyanate ester prepolymer; mix the cyanate ester prepolymer with 100g of diphenylphosphine oxide , 300g naphthol phenolic resin, 450g tetraglycidyl diaminodimethyl benzene mixed and stirred at 110°C for 1 hour, then added 60g titanium dioxide whiskers and 80g enol silicon ether, continued stirring for 50 minutes, and naturally cooled to obtain cyanic acid ester modified product; then crush the cyanate ester modified product, add 200g polyphenylene sulfide and 30g hollow alumina to the extruder, and extrude at 155°C to obtain halogen-free high dielectric performance part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com